Why Do Injection Molded Parts Crack After a Period of Time?

Injection molded parts are widely used across automotive, electronics, medical, and industrial sectors. While these components may initially pass inspections

Injection molded parts are widely used across automotive, electronics, medical, and industrial sectors. While these components may initially pass inspections

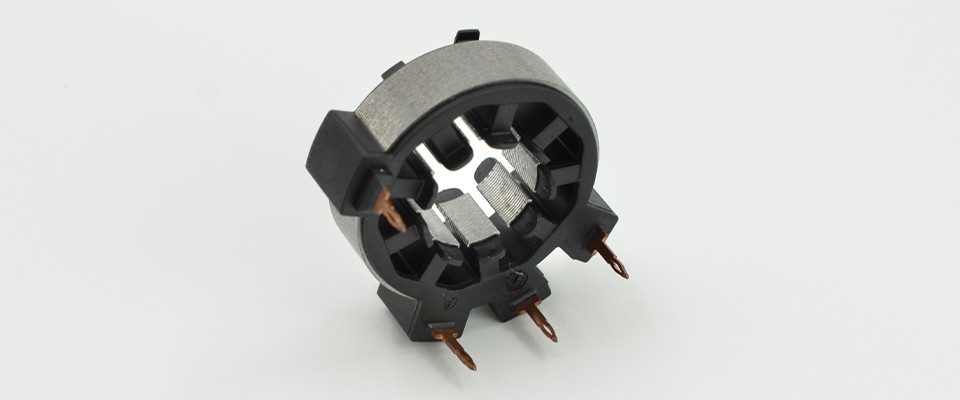

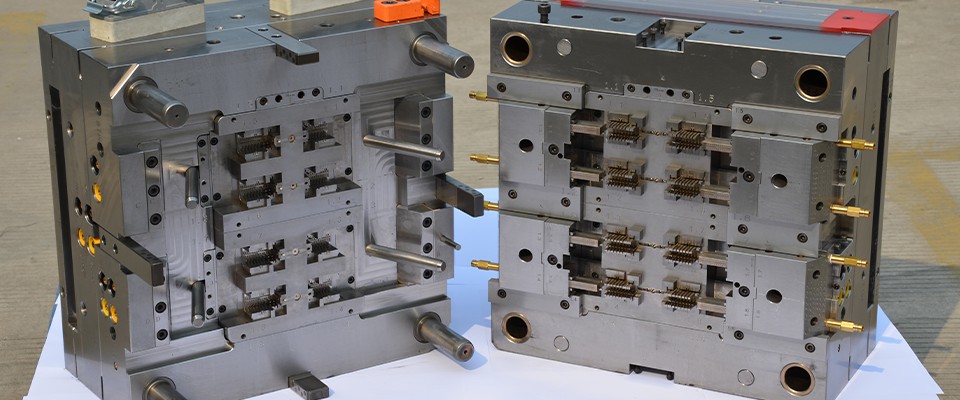

Insert molding is an advanced injection molding process where one or more pre-formed components (inserts) are placed into a mold,

In electric vehicles (EVs) and hybrid systems, high-voltage (HV) wires are critical for transferring power between the battery, inverter, motor,

Medical Luer connectors are widely used in IV sets, syringes, and infusion systems. Their mold design demands exceptional precision and

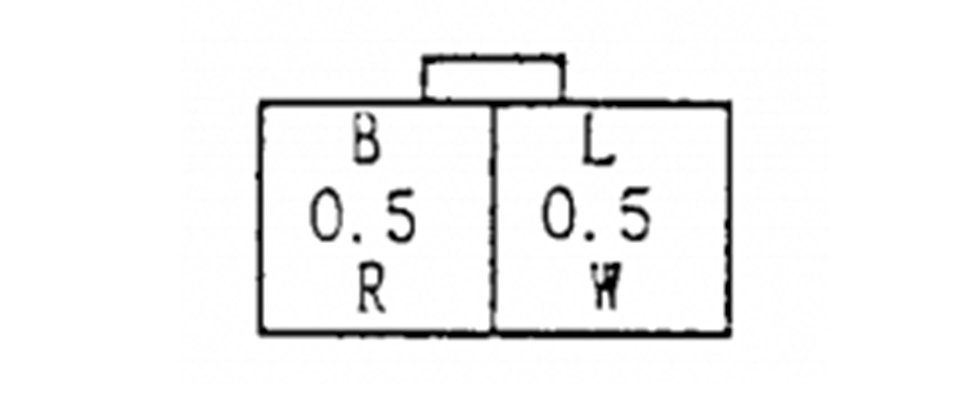

Understanding how information is presented on a wiring harness 2D drawing is the key to accurate interpretation. While different companies

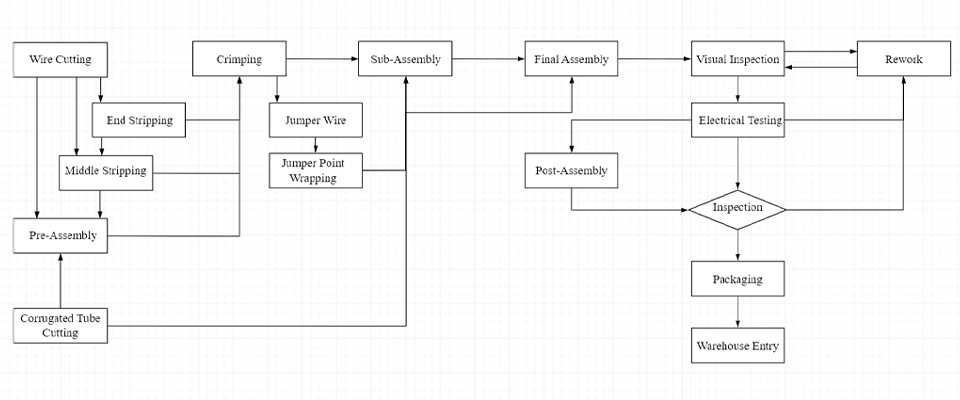

Definition of Process:According to the Oxford Dictionary, a process is defined as a series of actions taken in a specific

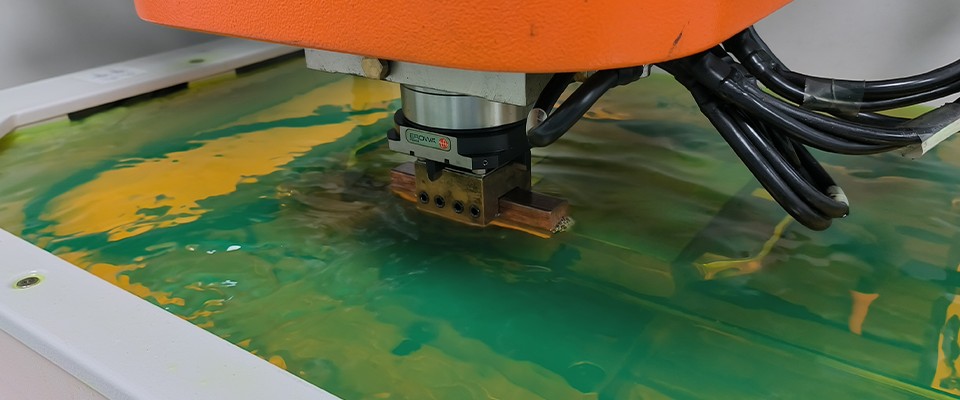

Electrical Discharge Machining (EDM) plays a critical role in precision mold manufacturing, especially for high-value components like micro connectors, IC

Understanding how information is presented on a wiring harness 2D drawing is the key to accurate interpretation. While different companies

The true cost of forceful disassembly goes far beyond the broken component: Surface Damage: Scratches and dents on critical surfaces