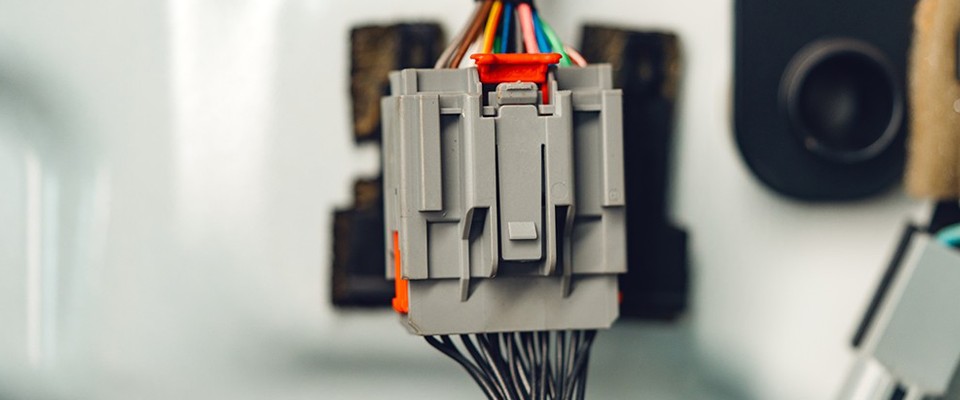

A connector is a device used to join two or more electrical circuits. It typically consists of a plug (male) and a socket (female). The male plug is also known as “plug” or “header,” while the female socket is referred to as “receptacle,” “socket,” or “jack.”

Connectors establish and break electrical connections through mechanical actions. Their primary functions include:

Transmitting signals or electrical power

Connecting or disconnecting electrical circuits

Why Are Connectors Important?

Connectors play an essential role in virtually all systems by enabling safe and reliable operation. They are responsible for the transmission of signals and power across various system components, directly affecting the performance and reliability of electronic devices and systems.

Key Benefits of Using Connectors:

Improved Manufacturing Efficiency: Simplifies the assembly process and accelerates mass production.

Ease of Maintenance and Upgrades: Facilitates easy maintenance and upgrades in the future.

Design Flexibility: Offers engineers greater flexibility when designing and integrating new products, ultimately reducing both volume and costs.

Main Types of Connectors

Connectors are classified in many ways based on their functions, signal types, electrical requirements, and operating environments. Let’s break down these categories for a clearer understanding.

1. Classification by Function:

Connectors can be classified based on the level and function of connection between electronic components, such as:

Component-to-Packaging: Connecting individual components to packaging.

Packaging-to-Circuit Board: Connecting packaging to circuit boards.

Board-to-Board: Connecting different circuit boards together.

Component-to-Component: Connecting various components within a system.

Component-to-I/O Interfaces: Linking components to input/output interfaces.

System-to-System: Interconnecting entire systems.

2. Classification by Signal Type:

Connectors can also be categorized based on the type of signal they transmit:

Power Connectors: For transmitting electrical power.

Signal Connectors: For transmitting electrical signals (e.g., data signals).

High-Frequency Connectors: Specifically designed for high-speed data transmission.

3. Classification by Electrical Requirements:

Connectors are designed to meet different electrical requirements based on their application:

General Connectors: Standard connectors suitable for general applications.

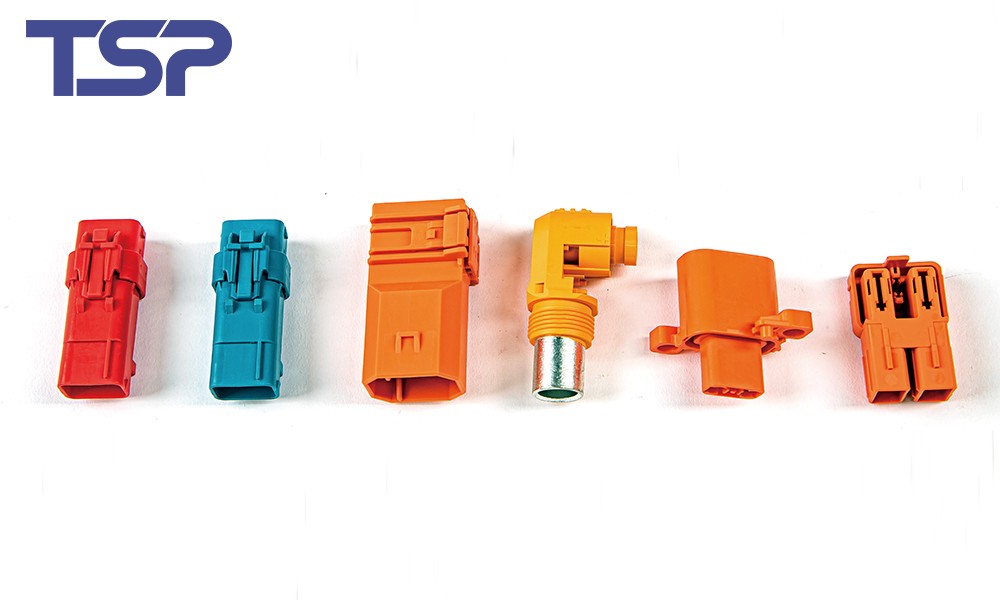

High-Power Connectors: Used for applications involving the transmission of large amounts of electrical power.

High-Voltage Connectors: Designed to handle high-voltage environments.

Pulse Connectors: Special connectors for high-speed pulse transmissions.

Low-Noise Connectors: Used in applications where minimizing electrical noise is critical.

Precision Coaxial Connectors: For high-precision signal transmission, such as in RF applications.

4. Classification by Environmental Conditions:

Many connectors are designed to perform under specific environmental conditions, including:

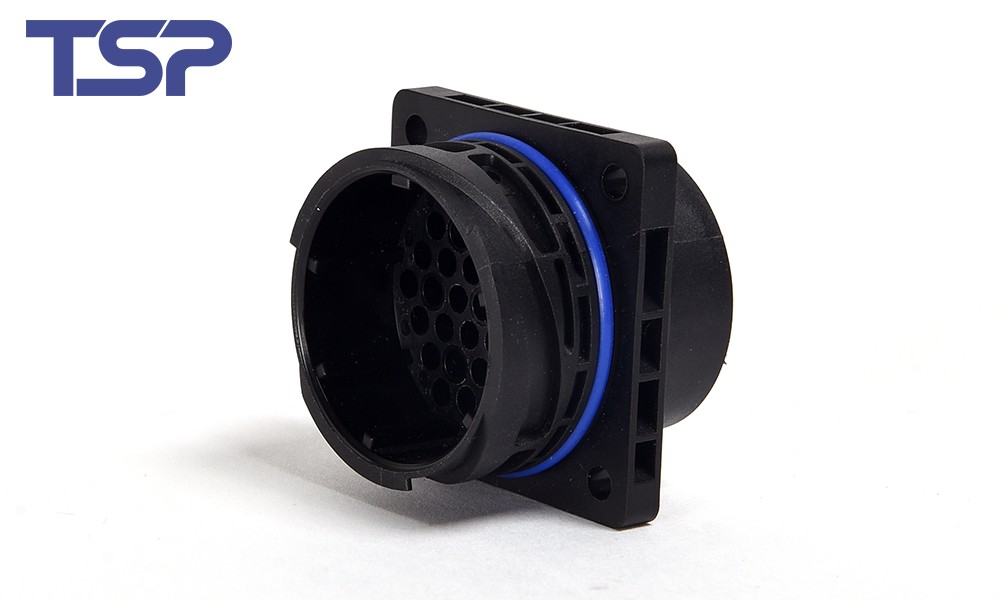

Sealed Connectors: Waterproof and dustproof, used for outdoor or harsh environments.

High-Pressure Sealed Connectors: Designed to withstand high-pressure conditions.

High-Vacuum Sealed Connectors: Used in vacuum environments.

Three-Proof Connectors: Designed for waterproof, dustproof, and anticorrosion applications. These are commonly used in industrial and military environments.

Radiation-Resistant Connectors: Made to resist exposure to radiation.

High-Temperature Connectors: For use in extremely hot environments.

Low-Temperature Connectors: Suitable for cold or freezing environments.

5. Classification by Shape:

Connectors also come in different shapes to suit specific applications:

Circular Connectors: Commonly used in military or aerospace industries. They have various connection methods, such as quick disconnect, threaded, automatic locking, push-pull, and direct insert-pull.

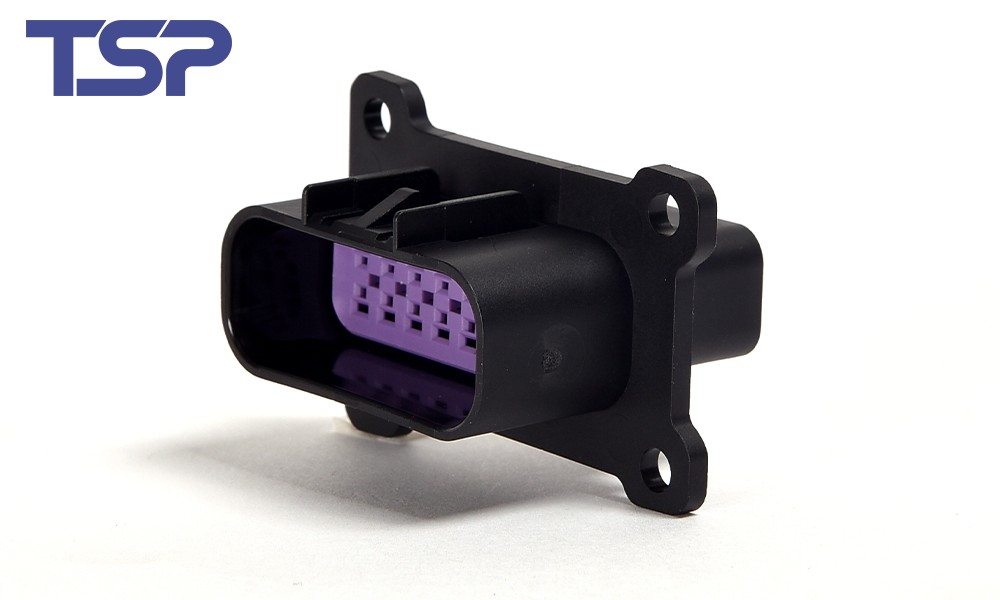

Rectangular Connectors: Widely used in industrial and consumer applications. Many PCB connectors are rectangular, and they typically use direct insert-pull or threaded locking methods.

6. Classification by Application Direction:

Connectors can be categorized by the direction and type of application:

RF Connectors: Used for high-frequency signal transmission in radio frequency (RF) applications.

Fiber-Optic Connectors: Used for light-based signal transmission in fiber-optic communications.

Non-Contact Connectors: Such as proximity switches, which work without direct physical contact.

How to Select the Right Connector

When choosing a connector, several factors should be considered to ensure optimal performance and reliability:

1. Current Capacity

For power connectors, it is essential to choose connectors that can handle the required current without overheating. Pay attention to the connector’s current rating and use a derating factor to avoid power loss.

2. Size and Dimensions

Ensure that the connector fits within the available space, especially in compact or limited spaces like single-board designs. Select connectors with the correct mounting style and dimensions.

3. Impedance Matching

For RF (radio frequency) signals, impedance matching is crucial. Improper impedance matching can result in signal reflection and data loss.

4. Shielding

Electromagnetic compatibility (EMC) is critical in many applications. Look for connectors with proper shielding to prevent signal interference, especially in communication devices.

5. Error-Proofing

Ensure the connector design prevents incorrect connections. Some connectors are polarized to ensure they can only be inserted in one way. This prevents mismatches and electrical damage.

6. Reliability

For long-term performance, connectors should provide reliable contact. For example, surface contact connectors are more reliable than point contact connectors, and pin-style connectors are typically preferred over spring connectors.

7. Environmental Considerations

Choose connectors that are suitable for the operating environment, whether it’s high temperature, humidity, extreme cold, or exposure to moisture.

8. Insertion/Removal Frequency

Some connectors are designed for frequent insertion and removal (hot-swapping). If you need to unplug and replug a connector regularly, choose one that can withstand high insertion cycles.

Connector Selection Criteria:

To make the best selection, consider all relevant factors, including:

Electrical Requirements: Ensure that the connector can handle the power and signals it will carry.

Mechanical Requirements: Ensure it fits within your system and can be installed easily without interference.

Environmental Suitability: Select a connector that is suited to the conditions it will operate in, whether it’s high or low temperature, high humidity, or corrosive environments.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone