Injection molded parts are widely used across automotive, electronics, medical, and industrial sectors. While these components may initially pass inspections and function perfectly, it’s not uncommon for them to crack or fail after weeks or even months of use.

Why does this delayed failure happen, even if the part was manufactured under seemingly ideal conditions?

As a precision mold manufacturer with expertise in insert molding and overmolding for wire harness components, we’ve helped many customers identify and resolve such issues. Here’s a complete breakdown of why cracks form over time—and what you can do to prevent them.

1. The Silent Killer: Environmental Stress Cracking (ESC)

The number one overlooked cause of delayed cracking is Environmental Stress Cracking (ESC). This occurs when a plastic part is exposed to a specific combination of residual internal stress and external chemical agents.

Real-world examples:

A PC/ABS automotive vent trim appears flawless after injection but cracks within weeks of being cleaned regularly with alcohol wipes.

A PE pesticide bottle cap splits in the warehouse even though it was stored undisturbed.

What’s happening?

Internal stress (from uneven cooling, high injection pressure, or poor part design)

External chemical exposure (like alcohol, oils, cleaning agents)

These two work synergistically, weakening the polymer structure until a crack propagates.

2. Which Plastics Are Most Vulnerable?

Plastics aren’t all the same. Some are far more prone to delayed cracking:

| Material Type | ESC Resistance |

|---|---|

| Amorphous plastics (e.g. PC, ABS, PMMA) | ✖ Low – More vulnerable |

| Crystalline plastics (e.g. PA66, POM, PBT) | ✔ Higher – Better resistance |

| High molecular weight polymers | ✔ Higher resistance |

Why? Amorphous plastics have looser molecular chains, making it easier for chemicals to penetrate and for stress to concentrate.

3. The Role of Chemical Agents

Even chemicals that seem mild can cause cracking:

Alcohols, esters, ketones (like ethanol or acetone) are common ESC triggers.

Low molecular weight solvents penetrate faster.

The closer the solvent’s solubility parameter is to the polymer, the higher the risk.

Example: PC and PMMA crack easily when exposed to isopropyl alcohol, especially if internal stress remains in the part from molding.

4. Sources of Internal Stress in Injection Molding

These stresses are often invisible—until it’s too late.

Main types of stress:

Thermal stress: Caused by uneven cooling.

Orientation stress: From fast flow and quick freezing of molecules.

Shrinkage stress: In thick/thin wall transitions.

Demolding stress: From poor mold design or excessive ejection force.

5. How to Prevent Delayed Cracking in Injection Molded Parts

Here are practical strategies we use in our manufacturing process to prevent cracking and ensure long-term durability:

A. Material selection

Choose high-ESC-resistant plastics for chemically exposed parts.

Use high molecular weight grades where possible.

B. Mold design

Avoid sharp corners and thick-thin transitions.

Include stress-relieving features such as radii or ribs.

For insert molding, preheat metal inserts to reduce stress from differential cooling.

C. Molding process optimization

Control injection speed, pressure, and cooling rate to minimize residual stress.

Optimize gate location and type (edge vs. pinpoint).

Extend cooling time where needed to ensure proper stress relief.

D. Post-molding treatment

Annealing can help reduce internal stress in amorphous plastics.

Limit exposure to aggressive chemicals in packaging, shipping, and cleaning stages.

6. How Wintone Helps Solve Cracking in Precision Molded Parts

At Wintone, we specialize in:

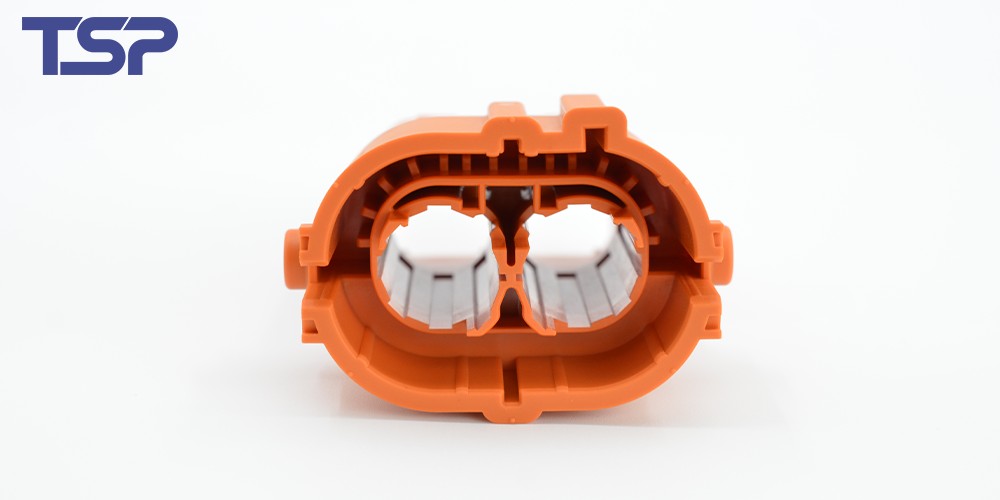

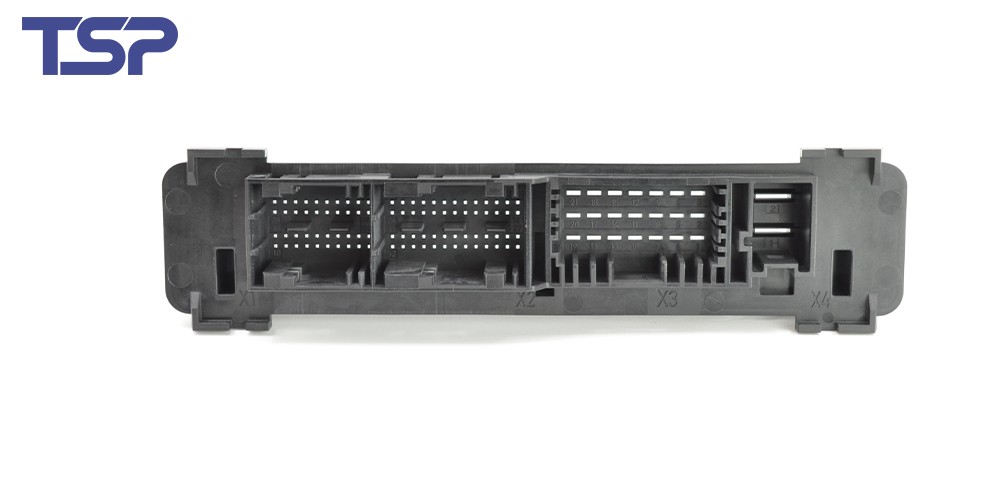

Insert molding for high-performance wire harness connectors and structural parts.

Using advanced materials such as our proprietary Z33 wear-resistant, low-humidity-sensitive engineering plastic.

Providing design feedback to improve part geometry and reduce stress concentration.

Offering low-shrink, high-torque solutions for precision gear applications, such as e-bike motors, planetary gear reducers, and silent transmission systems.

Conclusion

Delayed cracking in injection molded parts is often misunderstood. While mechanical stress or poor design may be suspected, Environmental Stress Cracking (ESC) is a more common culprit—especially when residual stress meets an unexpected chemical agent.

Understanding ESC and internal stress formation is critical to producing reliable, long-lasting parts.

Whether you’re designing high-precision gears, electrical connectors, or structural plastic parts, partnering with a knowledgeable mold manufacturer that understands both materials science and process control is essential.

Looking for crack-resistant, dimensionally stable injection molded parts?

Let’s talk about how our precision molds and insert molding expertise can support your next product.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone