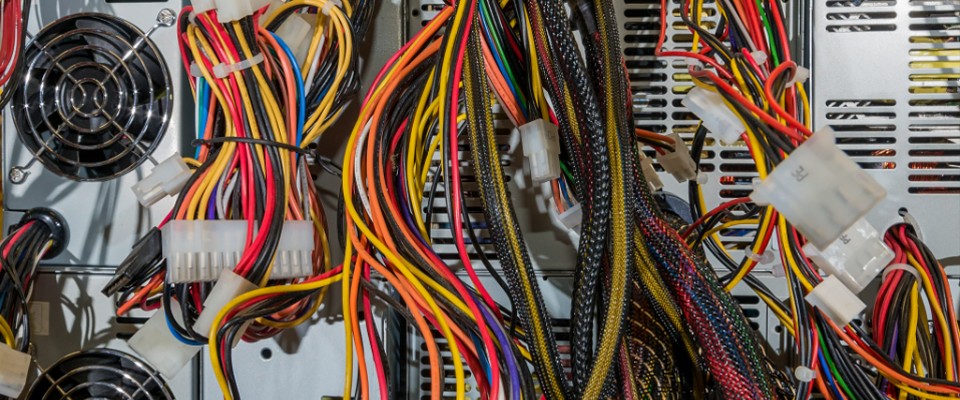

A wiring harness, also called a cable harness or wire loom, is a bundle of electrical wires. It includes terminals and connectors. This bundle transmits electrical power and signals. Many areas, such as cars, motorcycles, industrial machines, medical devices, and aerospace systems, use wiring harnesses.

Knowing what a wiring harness is, how it works, and why it is important is key in our electrified world. If you’re designing or building a product that involves electrical connectivity, this guide is for you.

1. Wiring Harness Definition

A wiring harness is an organized assembly of wires or cables. Strong materials like tape, conduit, or plastic hold these together. A wiring harness helps to safely and efficiently send electrical power or data signals throughout a system.

It simplifies installation, secures connections, reduces electrical shorts and vibrations, and improves system safety and performance. Instead of running dozens of separate wires, engineers can use a single harness assembly to streamline complexity.

2.What does a wiring harness include?

A typical wiring harness consists of:

- Wires & cables: Made of copper or aluminum, used to carry current or signals

- Connectors: Plug and socket components that interface with devices or components

- Terminals: Crimped metal pieces that connect wires to connectors

- Protective sheathing: Includes tubing, sleeves, or conduit to protect wires from heat, abrasion, or moisture

- Clips and grommets: Help mount the harness securely in the system

- Labels or color coding: Assist in maintenance and assembly

Every wiring harness is customized to match the unique design and functional requirements of the product it powers.

3. What Is the Purpose of a Wiring Harness?

The primary function of a wiring harness is to organize and protect the wires in an electrical system. But beyond that, a well-designed harness brings several benefits:

- Simplified installation: Instead of routing dozens of wires individually, one harness can connect multiple components at once

- Enhanced safety: Reduces risks of short circuits, fires, and connection failures

- Improved durability: Protective sleeving guards against moisture, heat, vibration, and abrasion

- Space efficiency: Harnesses are often tailored to fit tight spaces and engineered for 3D routing

- Standardization: Ensures consistent quality and easier maintenance or replacement

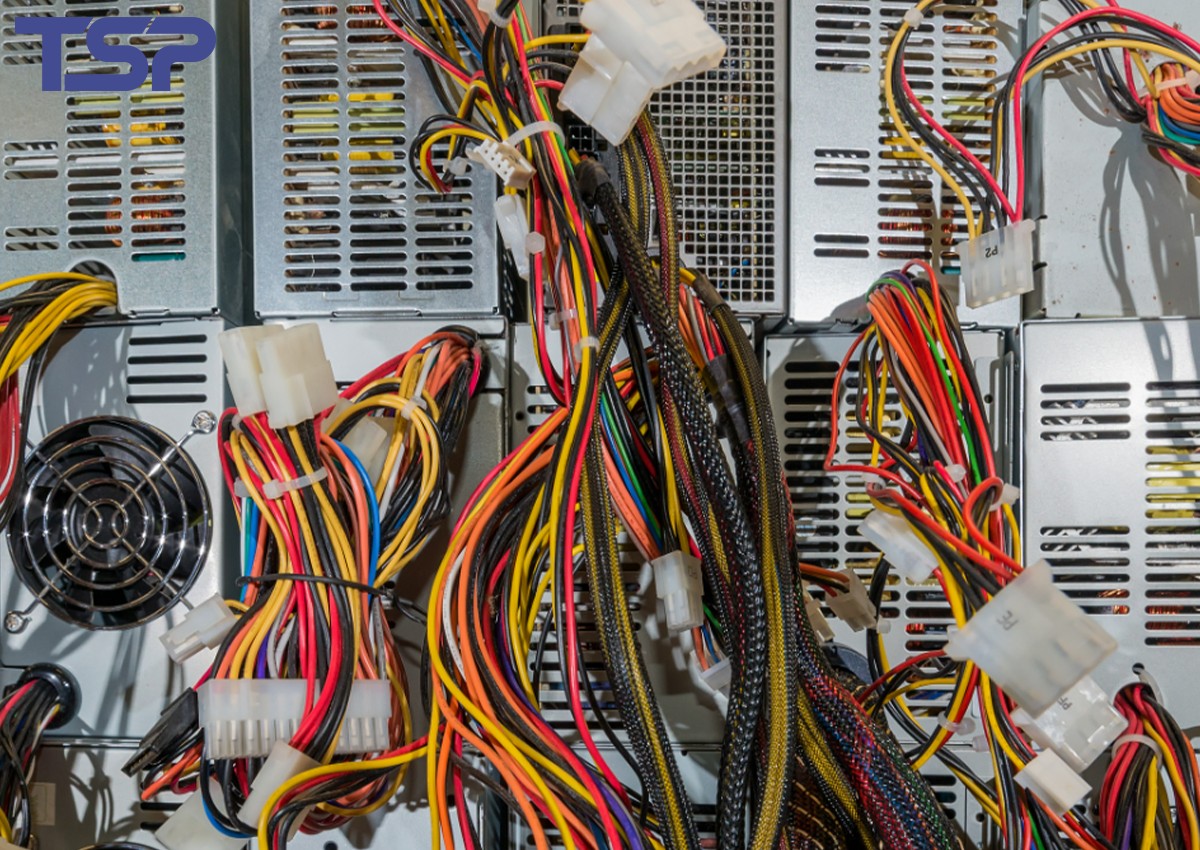

4. Where Are Wiring Harnesses Used?

Wiring harnesses are found in nearly every sector that uses electricity, including:

- Automotive and motorcycles: For power windows, airbags, headlights, infotainment, and engine control

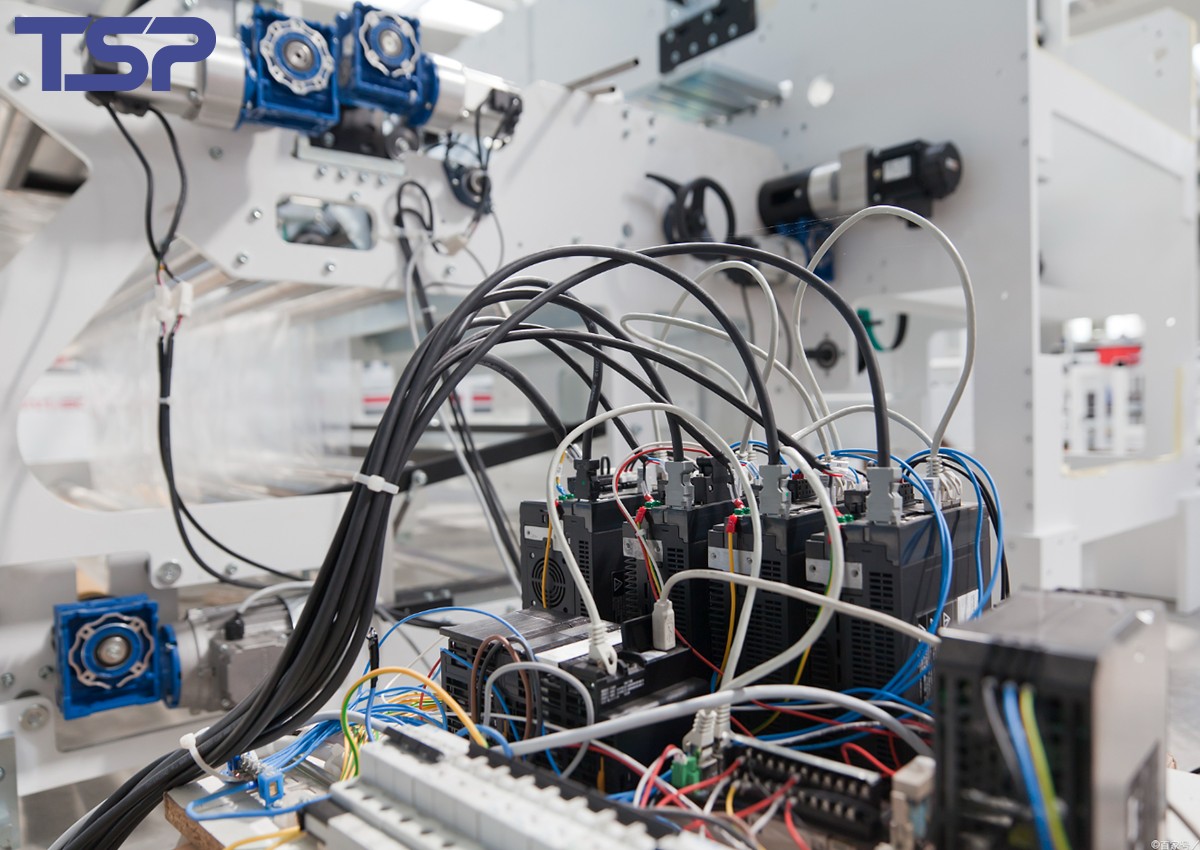

- Industrial machinery: Connects sensors, motors, control panels, and PLCs

- Medical devices: Used in imaging equipment, diagnostic tools, and surgical systems

- Consumer electronics: Inside appliances, gaming consoles, or wearables

- Aerospace and defense: Demands ultra-lightweight, EMI-shielded harnesses

- Renewable energy and batteries: Used to connect battery cells, inverters, and control units

- Electric vehicles (EVs): Feature high-voltage harnesses for drivetrain and charging systems

Each of these fields requires precision, reliability, and often customization, making precision wiring harness manufacturers indispensable partners.

5. Wiring Harness vs. Cable Assembly

These two terms are often confused, but they’re not the same:

| Feature | Wiring Harness | Cable Assembly |

|---|---|---|

| Composition | Multiple wires bundled, often exposed | One or more insulated cables inside a single protective jacket |

| Flexibility | High; wires may split into branches | Lower; more rigid |

| Applications | Complex systems like cars, control panels | Harsh environments like outdoors or heavy machinery |

| Protection | Moderate | Heavy-duty |

| Cost | Generally lower | Higher due to materials and protection |

Understanding this difference helps engineers choose the right solution for performance and cost-effectiveness.

6. How Are Wiring Harnesses Made?

Designing and manufacturing a wiring harness involves these steps:

- Requirements defining: Specify electrical, mechanical, and environmental needs.

- Schematic design: Create circuit diagrams and 3D routing models (ECAD + MCAD)

- Wire selection: Choose conductors, insulation, and shielding

- Assembly layout: Use nail boards or automated systems to guide layout

- Crimping and soldering: Attach terminals and connectors with high precision

- Bundling and protection: Apply sleeving, conduit, or heat-shrink tubing

- Testing: Check for continuity, insulation resistance, and signal integrity

- Labeling and packaging: For traceability and final assembly

Top manufacturers use both automated machines and skilled labor to ensure high quality, especially for custom and precision harnesses.

7. The Future of Wiring Harness Design

With the rise of electric vehicles, 5G, and smart manufacturing, wiring harnesses are evolving rapidly:

- High-voltage systems for EVs and hybrid cars

- Lightweight materials to reduce weight and improve fuel efficiency

- Digital twin and simulation tools to model electrical systems before production

- Recyclable materials and modular designs for sustainability

- Automated assembly and testing for higher consistency

Investing in an experienced and forward-looking harness manufacturer ensures your system stays ahead of the curve.

8. Why Work With a Precision Wiring Harness Manufacturer?

Not all manufacturers create wiring harnesses equally. If you need precise, custom, and reliable it with minimal defects, we’re the right manufacturer for you.

We specialize in:

- Custom-engineered it for automotive, industrial, battery, and medical applications

- Cleanroom-grade assembly for sensitive electronic systems

- High-mix, low-volume or high-volume production capacity

- In-house design + prototyping + testing

- ISO, IATF, and IPC-certified quality control

💡 We provide high-precision wiring harnesses tailored for EV batteries, medical devices, and industrial automation systems.

Conclusion

So, what is a wiring harness? It’s more than just wires—it’s the circulatory system of modern electrical systems. From simplifying installation to ensuring reliable operation, wiring harnesses are an essential yet often overlooked engineering component.

Looking for a reliable partner for custom, high-precision wiring harnesses? We’re ready to help.

👉 Contact us today to discuss your project and see how we can power your innovation.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone