Precision mold accuracy plays a critical role in industries such as connectors, wiring harness components, medical devices, and electronic parts manufacturing. Even minor dimensional deviations can lead to assembly issues, performance instability, or increased rejection rates.

So, what are the common factors affecting precision mold accuracy?

Based on industry best practices and high-performing manufacturing cases, mold accuracy is determined by a combination of material selection, mold design, machining precision, molding process control, and production environment.

1. Material Selection: The Foundation of Mold Accuracy

Mold Steel Quality and Stability

High-precision molds require premium-grade mold steels with:

Stable chemical composition

Uniform heat treatment

Low internal stress

Poor-quality steel or improper heat treatment can cause deformation during machining or long-term production, directly reducing mold accuracy.

Plastic Material Shrinkage Characteristics

Different plastic materials exhibit different:

Shrinkage rates

Crystallization behavior

Thermal expansion properties

If these characteristics are not fully considered during mold design, final part dimensions may deviate even when mold machining accuracy is high.

2. Mold Design Factors: Defining the Accuracy Limit

Structural Design Rationality

Precision mold accuracy depends heavily on:

Gate location and runner design

Uniform cooling system layout

Effective venting structures

Unreasonable mold design often leads to uneven filling, internal stress concentration, warpage, or dimensional instability.

Tolerance Allocation and Assembly Fit

In precision molds, each component’s tolerance directly affects overall performance. Scientific tolerance allocation ensures stable assembly and long-term accuracy during high-volume production.

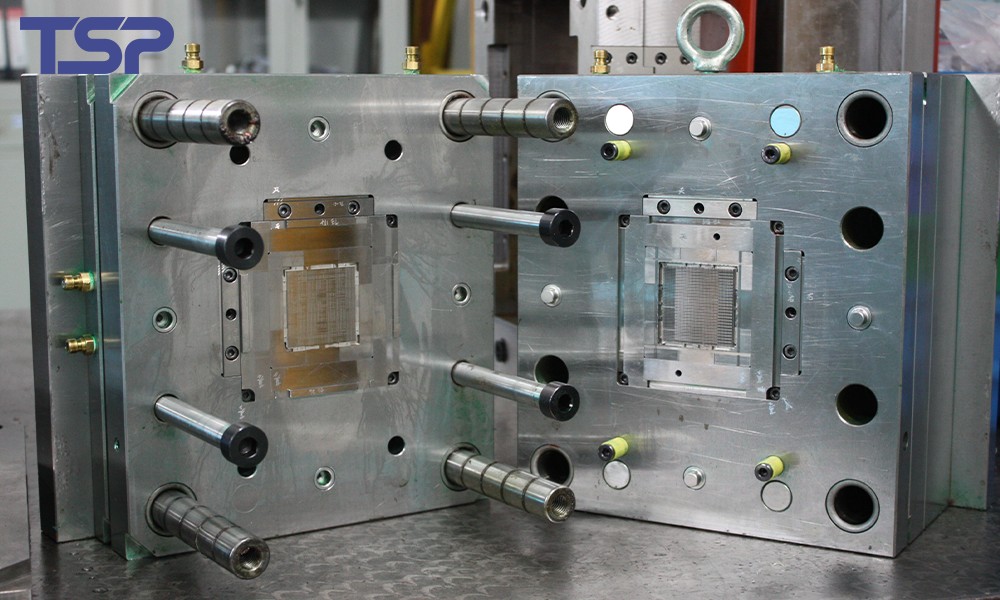

3. Mold Machining Precision: Turning Design into Reality

Machining Equipment and Technology

High-accuracy molds rely on:

Advanced CNC machining

Precision grinding

EDM and fine finishing processes

The repeatability and stability of machining equipment directly influence dimensional consistency between mold components.

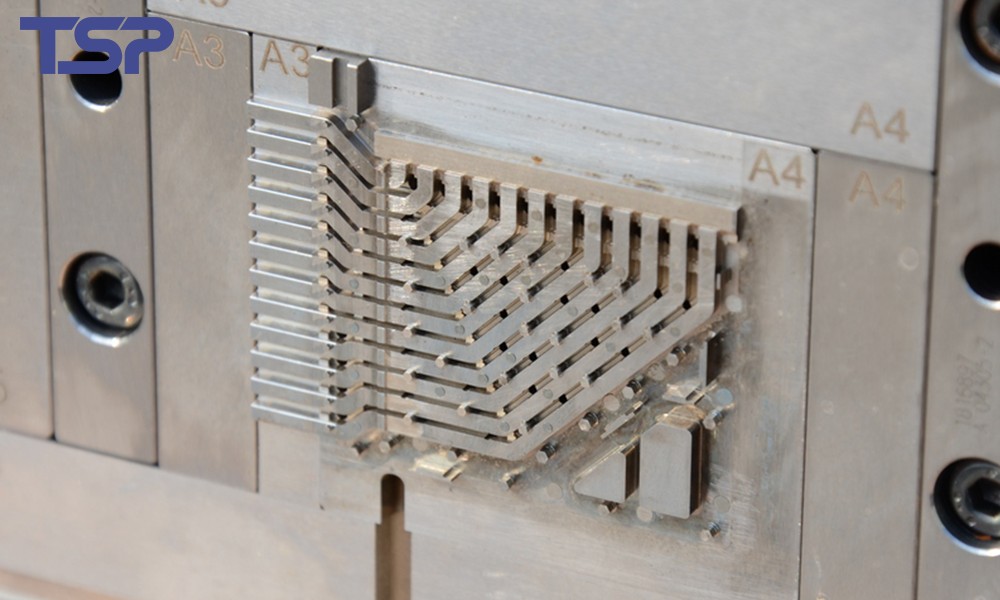

Process Control During Machining

Precision mold manufacturing requires strict control of:

Tool wear

Thermal deformation

Multi-stage machining and stress relief

Experienced manufacturers focus on these details to maintain micron-level accuracy.

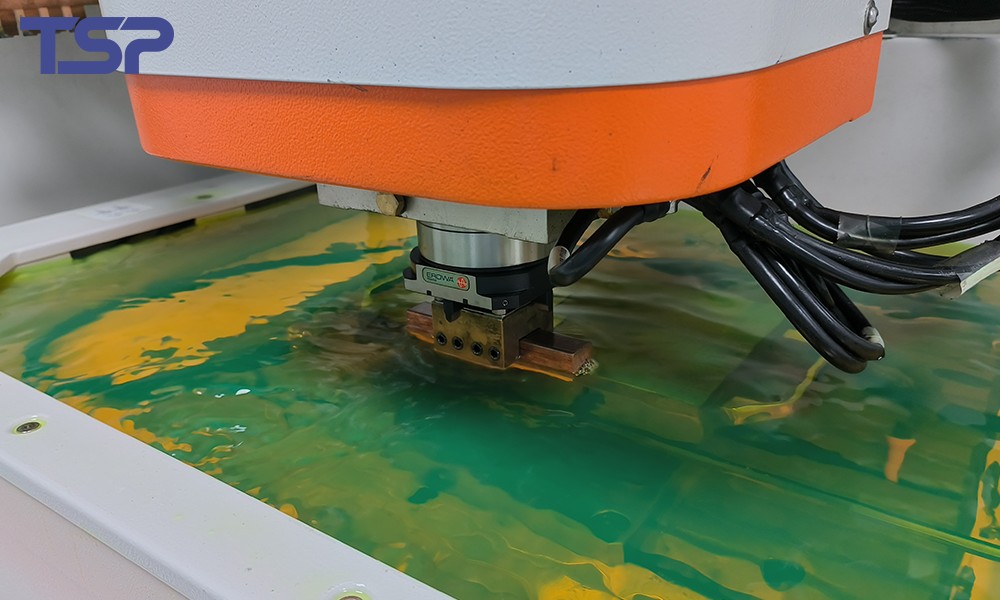

4. Injection Molding Process Parameters: Ensuring Accuracy Repeatability

Even a highly precise mold cannot guarantee accurate products without proper molding process control.

Key process parameters include:

Injection pressure and speed

Mold temperature control

Holding pressure and cooling time

Precision molds typically operate within narrow process windows, requiring experienced technicians and stable molding systems.

5. Equipment and Production Environment

Injection Molding Machine Stability

High-precision molding requires machines with:

High repeatability

Stable pressure control

Accurate temperature regulation

Equipment fluctuations can directly cause dimensional variation in molded parts.

Environmental Conditions

Temperature and humidity changes in the production environment can subtly affect material behavior, especially during long-term mass production.

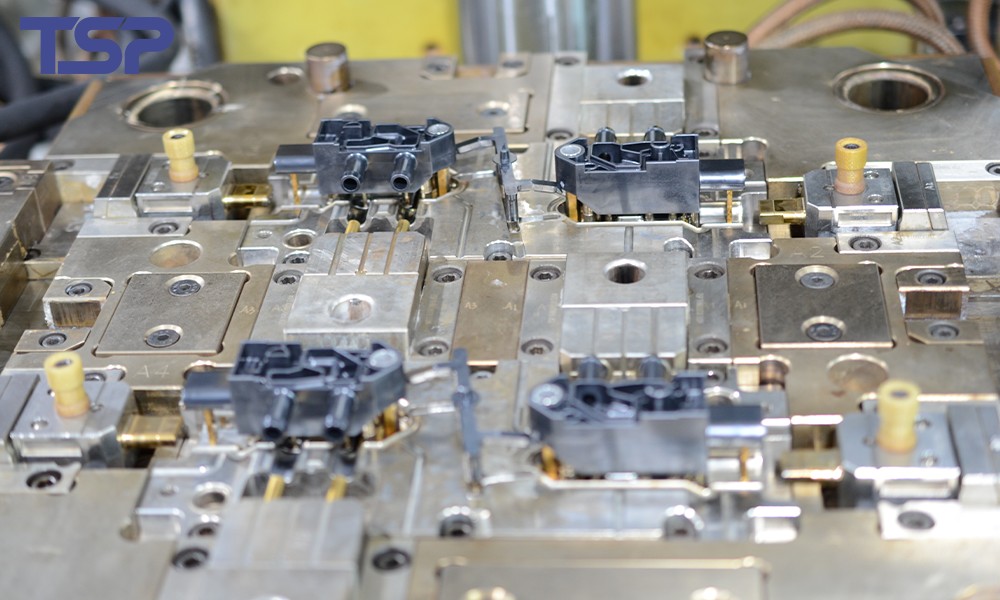

6. Why Choosing an Experienced Precision Mold Manufacturer Matters

Precision mold accuracy is never determined by a single factor. It is the result of a complete manufacturing system, including design expertise, machining capability, process control, and quality management.

Professional manufacturers like tsp.cn focus on:

Customized mold design based on product application

Stable machining and quality control processes

Consistent accuracy across mass production cycles

This is particularly critical for high-precision components such as connectors and wiring harness parts, where reliability and dimensional consistency are essential.