In today’s fast-paced electronics and automotive sectors, precision matters more than ever—especially when it comes to injection-molded wire harness components. These parts not only require perfect dimensional stability, but they also demand durability, insulation reliability, and compatibility with electrical performance standards.

So, what really impacts the precision of these molded parts? Whether you’re a product designer or a sourcing manager, understanding these factors will help you reduce defects, lower production costs, and choose the right manufacturing partner.

1. The Role of Shrinkage in Precision Molding

Plastic shrinkage is the most influential factor in dimensional accuracy. It occurs during the cooling phase of the injection molding process. Types of shrinkage include:

Thermal shrinkage – caused by temperature drop during solidification

Orientation shrinkage – from polymer alignment during high-speed flow

Compression & elastic recovery shrinkage – occurs when pressure is released

Choosing the right plastic material (such as PA66 with GF) and controlling the mold temperature can significantly improve stability.

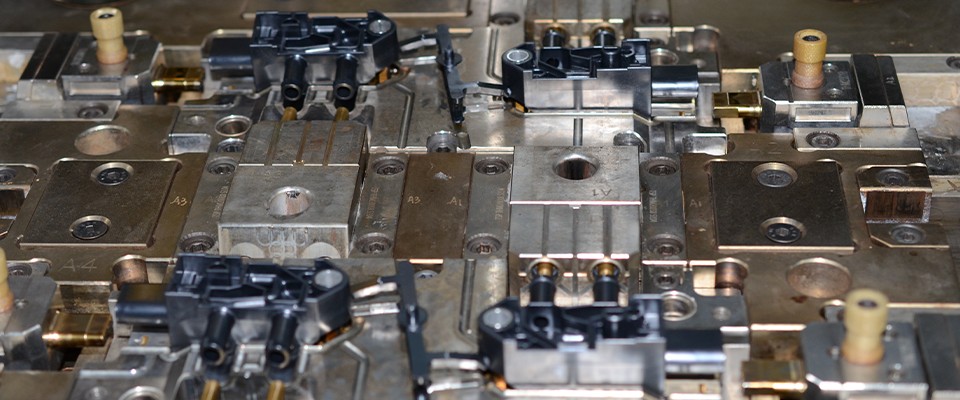

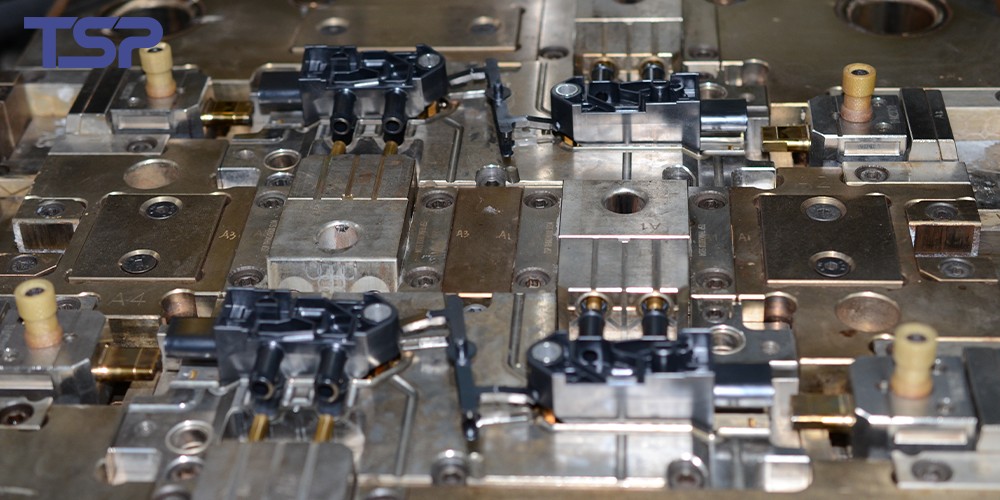

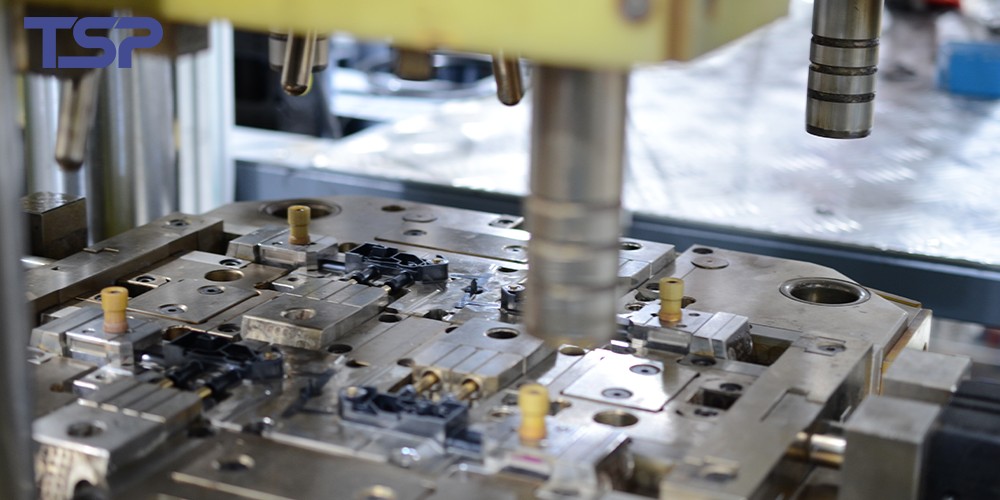

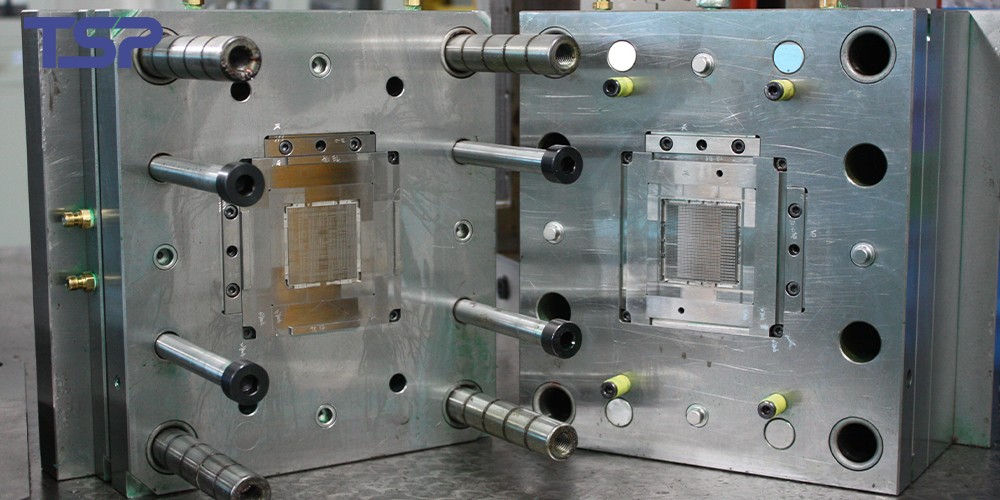

2. Mold Design: Accuracy Starts at the Core

A high-precision mold must have:

Tight tolerance cavities and cores

Proper alignment of parting lines

Optimized flow channels to avoid weld lines and voids

Venting and cooling systems to maintain temperature uniformity

For wire harness components—especially for connector housings or overmolded cable exits—every micron counts.

3. Injection Parameters Matter

Process settings play a huge role in precision:

| Parameter | Impact on Precision |

|---|---|

| Injection speed | Affects flow and part filling |

| Holding pressure | Maintains cavity pressure |

| Melt temperature | Influences flowability and shrinkage |

| Cooling time | Controls dimensional stability |

Consistent settings, coupled with real-time process monitoring, help reduce batch variability.

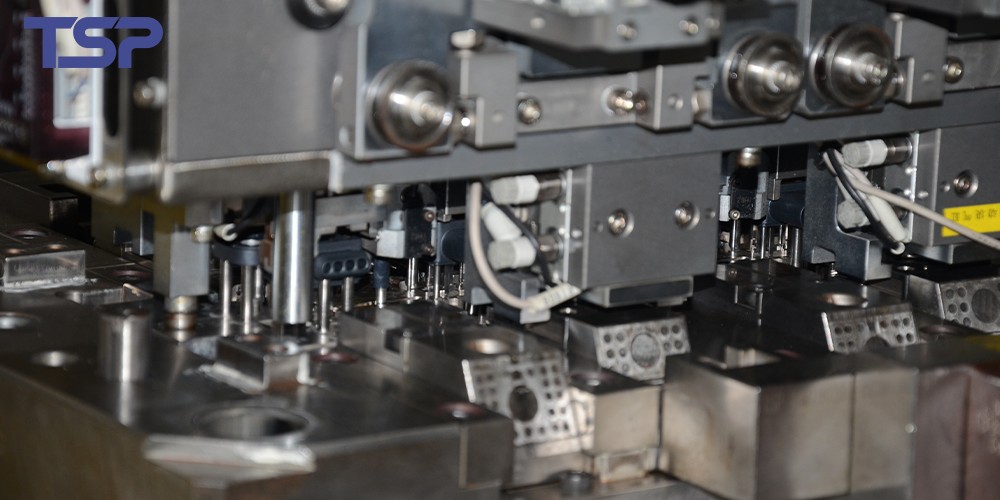

4. Machine Capabilities and Calibration

Using high-end machines with precise servo control and repeatable injection units ensures consistent part quality. Equally important is routine maintenance and calibration—a poorly maintained press can cause tolerance drift, flash, or short shots.

At our facility, we use micro-tolerance molding machines combined with precision-built molds to meet the strict demands of automotive and medical wire harness clients.

5. Material Matters: Choose Wisely

Not all plastics behave the same. When it comes to precision:

High-performance polymers like PBT, PA66, or LCP are preferred

Glass-filled materials reduce shrinkage but require better tooling

Consistent material batches are key—variations can ruin precision

We work closely with certified material suppliers to ensure consistent mechanical and thermal properties in every injection batch.

6. Quality Inspection: Beyond Visual Checks

Precision requires measurement. We employ:

CMM (Coordinate Measuring Machines)

2D/3D profile projectors

Pin gauge and tolerance testers

Each part undergoes dimensional inspection before shipment—especially important for terminal housings or sensor overmolds where fitting errors can cause full-system failure.

Why Partner With Us?

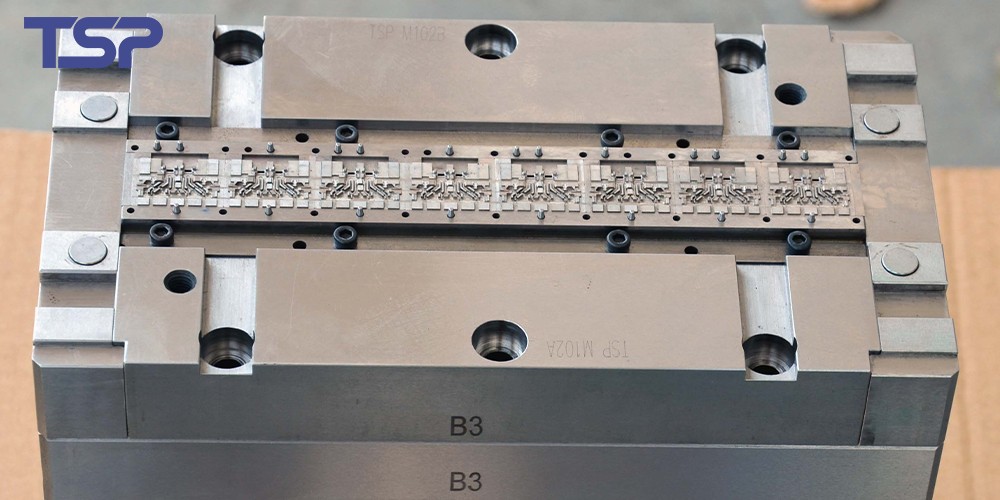

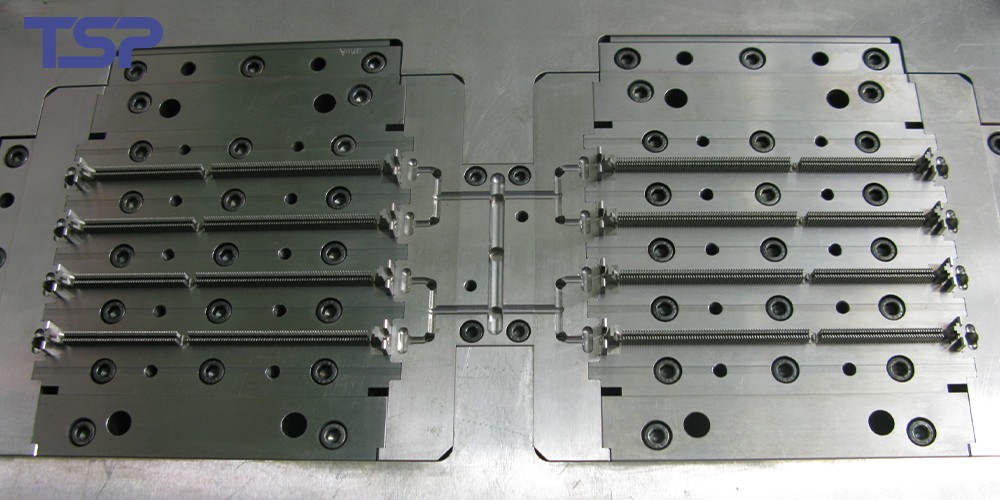

At TSP, we specialize in:

✅ Precision injection molding for wire harness components

✅ Custom mold design and in-house mold making

✅ Metal stamping for terminals and brackets

✅ Full-service wire harness assembly

Whether you’re developing EV battery harnesses, sensor connectors, or medical signal lines—we offer end-to-end manufacturing that ensures speed, precision, and quality.

Final Thoughts

Precision injection molding for wire harness components is a delicate balance of material, mold, process, and control. Small errors can lead to big issues—short circuits, poor fitting, or even recalls. That’s why choosing the right manufacturing partner is crucial.

Need reliable, dimensionally-accurate plastic components? Contact us today for a custom quote or design review.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone