Introduction

With the global transition towards sustainable transportation, electric vehicles (EVs) are rapidly gaining popularity. Unlike traditional internal combustion engine vehicles, EVs require a completely new electrical transmission system to ensure that high-power energy is safely and efficiently transferred from the battery to the electric motor. Connectors play a crucial role in this system. They are not only responsible for power transmission but also for data communication, safety performance, and even the overall durability and performance of the vehicle.

This article will explore how connectors are vital to EVs, ensuring efficient power transfer, stable vehicle performance, and discussing the future development of connector technology.

Connectors in Electric Vehicle Systems

In electric vehicles, connectors play a primary role in ensuring safe and reliable power and data transmission. Multiple systems inside and outside the EV rely on connectors to integrate components like batteries, electric motors, sensors, and charging interfaces.

Power transmission

High-voltage connectors are responsible for transmitting high power from the battery to the electric motor, ensuring the EV operates properly. These connectors must handle high voltages and currents, adhering to stringent safety standards.

Data communication

Modern EVs rely on a network of complex sensors for real-time monitoring and data processing. Low-voltage and data connectors are used to transfer information between these sensors and control units, allowing the vehicle to manage the battery, motor, and various safety systems accurately.

Based on their functions, connectors in EVs can be categorized as:

• High-voltage connectors: Handle high-power transmission in the powertrain.

• Low-voltage connectors: Used in auxiliary systems and internal communications.

• Data connectors: Responsible for transmitting sensory and control data within the vehicle.

Challenges of Power Transmission

The primary challenge for EV connectors is handling high currents and voltages. As battery capacity increases and charging speeds improve, connectors must endure higher power loads. Typically, an EV’s battery system operates above 400V, and in high-performance models, this can reach up to 800V, while charging currents may exceed hundreds of amperes.

Selecting the right connector is crucial, as they must not only ensure efficient power transmission but also prevent energy loss, overheating, and electrical arcing. The quality of insulation materials, optimized contact resistance, and secure connections directly affect the safety and longevity of the EV.

Advanced Connector Technologies

To address these challenges, advanced connector technologies have been developed to ensure safer and more efficient power transmission.

Efficient power transmission

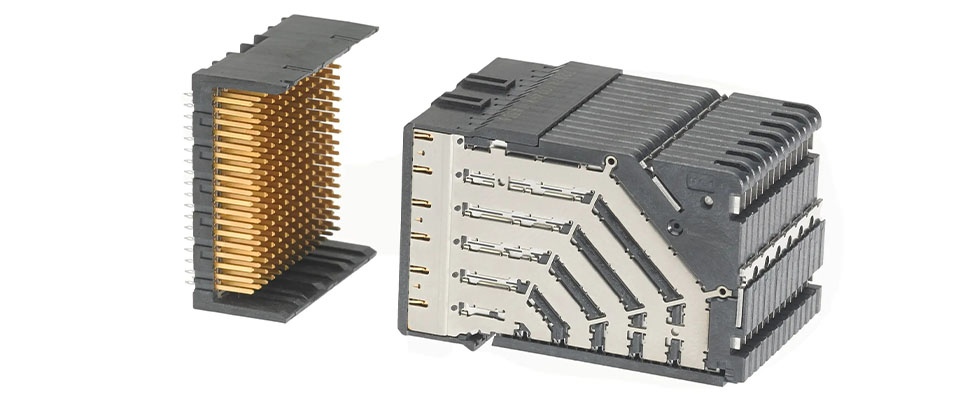

The next generation of connectors uses low-resistance, high-conductivity materials such as copper alloys or silver-plated contacts to reduce energy losses and enhance transmission efficiency. These designs maintain contact stability during high-current flow, improving the lifespan and performance of the connector.

Durability and reliability

Given that EVs may be exposed to high temperatures, vibrations, and moisture, connectors need exceptional durability. Many advanced connectors offer heat resistance, vibration resilience, and are designed with waterproof and dustproof features, achieving high IP (Ingress Protection) ratings such as IP67 or IP68, ensuring stability even in harsh environments.

Thermal management

High-power transmission generates significant heat. If this heat is not properly dissipated, it can degrade connector performance or lead to failure. Modern connectors incorporate thermal management designs, using conductive materials or heat sinks to efficiently lower operating temperatures, enhancing reliability.

The Role of Connectors in Vehicle Performance

The performance of connectors is directly linked to the overall efficiency of EVs. Efficient power transmission can significantly enhance motor output efficiency, thereby improving vehicle acceleration and extending driving range. On the other hand, poorly designed connectors can lead to power losses, reducing battery range or damaging critical components.

High-performance electric vehicles, especially sports cars or long-range models, demand connectors with higher power density to accommodate extreme power transmission scenarios. Moreover, as EVs become more intelligent, connectors not only transmit power but must also handle high-speed data communication to support features like adaptive cruise control and autonomous driving.

Connectors in Charging Systems

Connectors play a vital role in EV charging systems. With the growing adoption of EVs, consumers are demanding faster charging times, making fast-charging technology a mainstream requirement. Connectors must support high-power transmission, working under high voltage while ensuring safety and stability.

Currently, several charging connector standards exist, including:

• CCS (Combined Charging System): Widely used in Europe and North America, supporting DC fast charging.

• CHAdeMO: Predominantly used in Japan and gradually expanding globally, supporting bi-directional charging.

• GB/T: The primary standard in the Chinese market, adapted to local power transmission needs.

With the development of wireless charging technology, future connectors may shift away from physical interfaces, using wireless connectors to transfer energy via electromagnetic fields. This will revolutionize the charging experience, simplifying operations and enhancing user convenience.

Future Trends and Developments

In the future, EV connectors will continue to evolve toward lighter, modular, and more intelligent designs to meet higher technological demands.

• Lightweight materials: To reduce overall vehicle weight and increase range, lightweight materials such as aluminum alloys and composite materials will be increasingly used in connector manufacturing. These materials not only reduce weight but also offer high conductivity while improving durability.

• Modular design: Modular connectors can be quickly replaced or upgraded based on the specific needs of the vehicle, enhancing the maintainability and flexibility of EVs. This design approach will also reduce production and maintenance costs.

• Intelligent management: With the rise of connected vehicle technology (V2X) and autonomous driving, connectors will increasingly integrate more data transmission and management capabilities. Future connectors will not only serve as a medium for power transfer but will also become key nodes in the vehicle’s smart network, enabling intelligent coordination of power and data management.

Conclusion

In conclusion, connectors are a critical component in electric vehicle technology, determining the efficiency of power transmission, operational stability, and overall vehicle performance. As connector technology continues to advance, the next generation of EVs will be more efficient, offer safer charging experiences, and feature greater intelligence. In this technology-driven era, the development of advanced connectors will undoubtedly propel the EV industry towards a more mature stage.