In today’s competitive manufacturing landscape, producing high-precision molds demands not only exceptional design capabilities but also cutting-edge technologies and world-class equipment. At our precision mold manufacturing facility, we implement seven industry-leading machining technologies to deliver exceptional accuracy, efficiency, and quality in every mold we produce. Whether you’re an industry expert or exploring mold manufacturing for the first time, this article offers a comprehensive guide to the technologies driving precision mold production—and why you should trust your project with us.

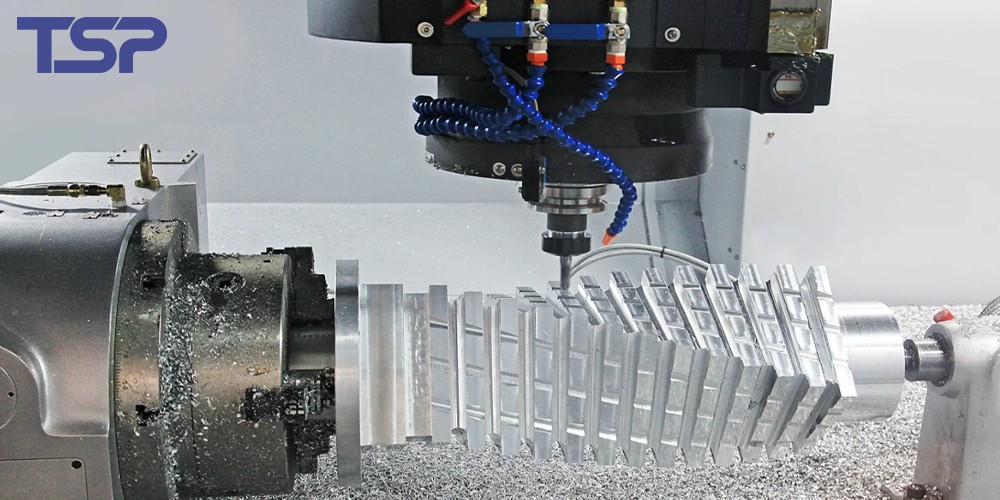

1. High-Speed CNC Milling

CNC milling is the foundation of modern plastic mold making. With advanced 5-axis milling capabilities, we can precisely machine complex 3D geometries with outstanding accuracy.

Our facility is equipped with high-speed CNC machines from MORISEIKI and Makino, offering:

Accuracy up to 0.002mm

Surface roughness Ra < 0.15μm

Capable of machining hardened steel up to 60HRC

Thanks to 5-axis technology, we minimize repositioning and achieve high-quality finishes, ideal for intricate mold cavities and cores.

2. Wire EDM (Electrical Discharge Machining)

Wire EDM is essential for machining intricate contours and sharp internal corners that milling cannot reach.

We use top-of-the-line wire EDM machines from AgieCharmilles and Sodick, capable of:

Accuracy: 0.002mm

Surface roughness: Ra 0.05μm

Ideal for inserts, ejector pin holes, and complex punch/die elements

Wire EDM plays a vital role in producing high-performance stamping and injection molds.

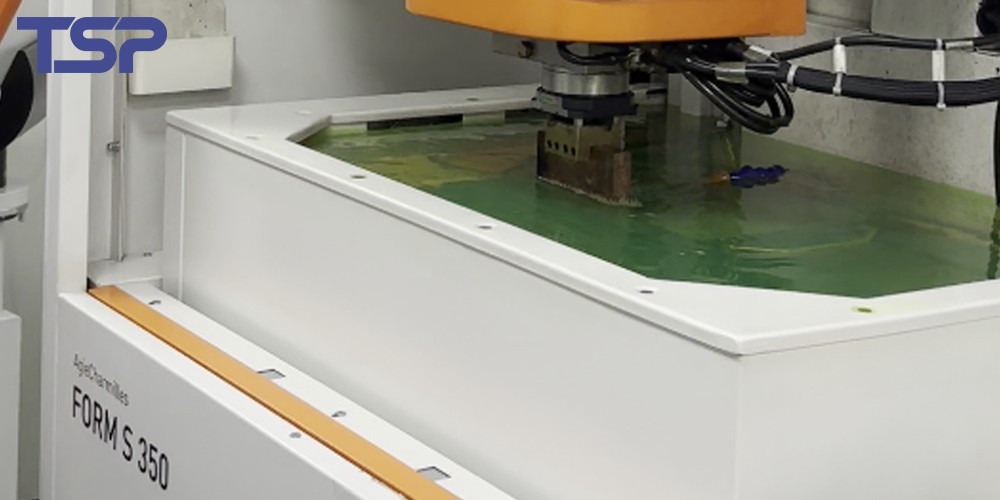

3. Sink EDM (Die-Sinking EDM)

For deep cavities, narrow slits, and complex geometries, sink EDM delivers unmatched precision.

With machines from AgieCharmilles and Makino, we offer:

Accuracy: 0.002mm

Mirror surface finishes (Ra < 0.1μm)

Precise sharp-corner finishing up to 5μm

Sink EDM complements CNC milling by enabling precision machining in areas unreachable by conventional cutting tools.

4. Precision Grinding

Grinding is critical in finalizing surface accuracy and achieving tight tolerances, especially on hardened steel components.

Our grinding capabilities include:

Surface Grinders from OKAMOTO: Accuracy 0.001mm

Profile Grinders from WAIDA: Accuracy 0.001mm

We perform flat grinding, cylindrical grinding, and optical profile grinding to ensure perfect finishes on inserts, slides, and mold bases.

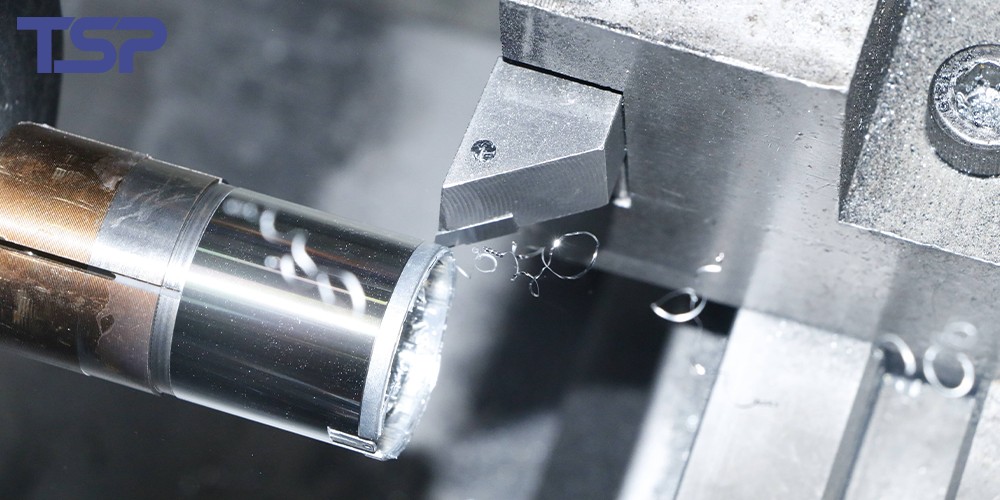

5. CNC Turning (Lathe Processing)

We use CNC turning for high-precision round components, such as circular inserts, cores, and guide sleeves.

Thanks to our advanced CNC lathes:

Complex geometries are easily programmable

Multi-tool changing ensures faster production

Ideal for mass production of precision round parts

In some cases, CNC turning even replaces grinding, reducing processing time and costs.

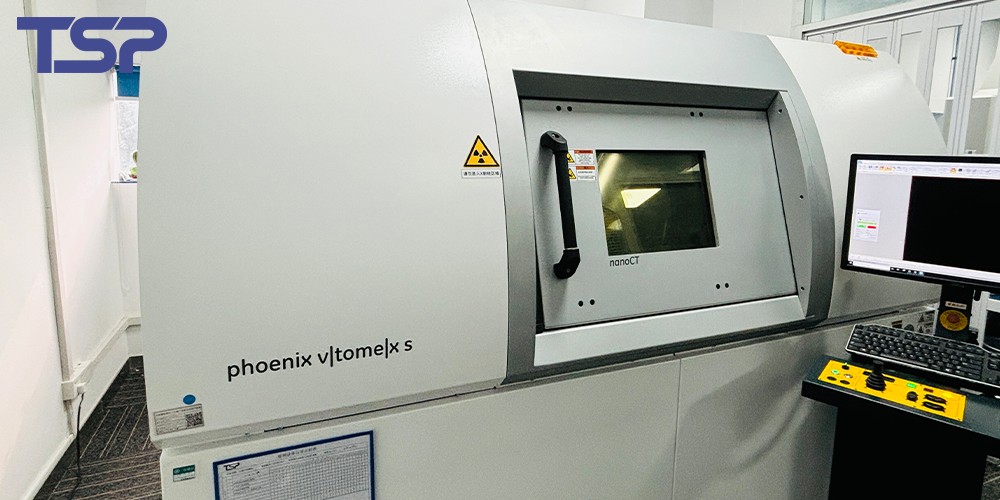

6. Precision Measurement & Quality Control

Quality is at the heart of everything we do. We employ industry-leading metrology tools to inspect every mold component:

CMMs (Coordinate Measuring Machines) from ZEISS and Mitutoyo

Vision Measuring Systems for complex geometries

These tools ensure:

Measurement accuracy within microns

Full 3D tolerance inspection

Reverse engineering capabilities

We also utilize high-resolution X-ray computed tomography (CT) systems such as the Phoenix v|tome|x s, enabling full 3D internal inspections without destroying the part. This advanced non-destructive technology allows us to:

Detect internal defects, voids, and cracks in complex components

Perform high-precision 3D metrology for internal and external geometries

Support reverse engineering of highly complex parts with full volumetric data

CT scanning ensures that every mold and molded part meets the strictest quality standards—inside and out.

7. Quick Clamping & Automation Systems

Efficiency is maximized with System 3R and EROWA quick clamping systems, enabling:

Repositioning accuracy within 3μm

Setup time reduced to under 1 minute

Seamless integration between milling, EDM, and measuring stations

Our workshop also embraces semi-automated and fully automated workflows using robotic handling and software integration, ensuring faster turnaround and consistent quality.

Why Choose Us as Your Mold Manufacturing Partner?

We are more than just a mold shop. With 140+ high-precision machines from global brands including Yamada, Kyori, Micron, CF, Arburg, Fanuc, Sumitomo, ENGEL, Nissei, and Multiplas, we handle everything from tooling to large-volume molding production.

Our capabilities:

Injection machines ranging from 30T to 320T

Press machines from 40T to 200T

Full in-house mold design, tooling, and production

Every product we deliver reflects our commitment to precision, efficiency, and reliability.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone