The true cost of forceful disassembly goes far beyond the broken component:

Surface Damage: Scratches and dents on critical surfaces lead to flash, burrs, and product defects.

Invisible Cracks: Stress points become ticking time bombs, causing sudden mold failure.

Lost Accuracy: Bent guide pins or distorted mold bases throw off alignment forever.

Soaring Costs: Emergency repairs, remakes, line shutdowns… every hammer blow bleeds your profit.

The solution? Embrace a gentle, methodical approach to mold disassembly.

🛠 Principle 1: Clean and Inspect Before Disassembly

Disassembly is not a race—it’s a strategic operation. Dirt, residue, and corrosion are hidden enemies.

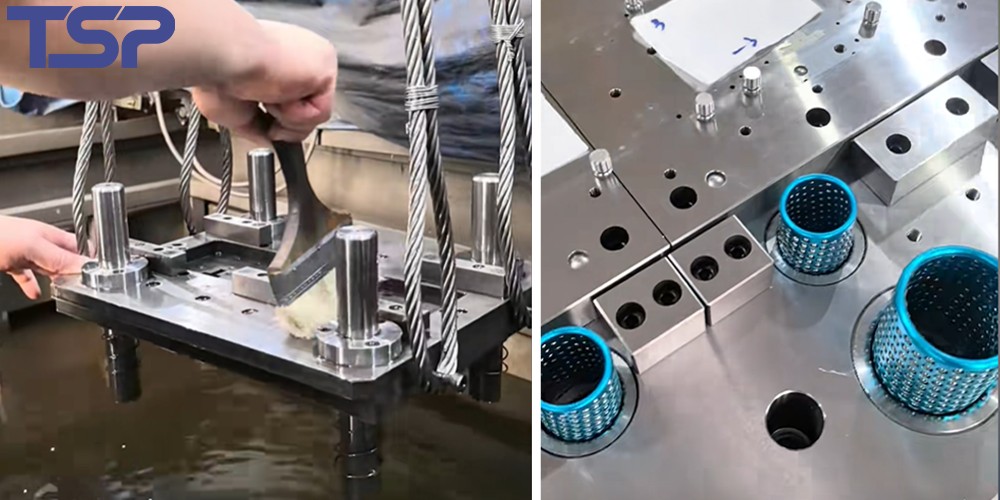

✔ Complete Cleaning:

Use solvent or cleaner to remove grease, plastic residue, and rust.

Clear ejector pinholes, guide pin holes, and cooling channels with air or brushes.

Dry thoroughly and apply light anti-rust oil to prevent further corrosion.

✔ Careful Inspection:

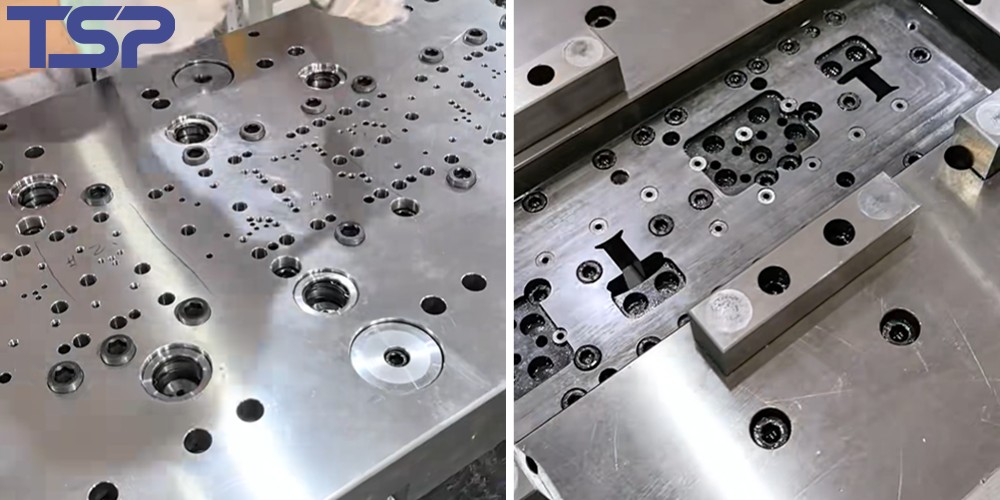

Always review the 2D/3D mold drawing first, if available.

No drawing? Take photos/videos of the mold from multiple angles.

Label and mark every ejector, insert, or small part clearly to avoid confusion later.

👉 Takeaway: Cleaning is the lubricant for smooth disassembly. Inspection is your GPS for safe reassembly.

🔧 Principle 2: Use the Right Tools – Precision Over Power

Retire the steel hammers! Use controlled, specialized tools:

✔ Use Mold’s Built-in Ejection System First

Engage the ejection system of the injection press for gradual, small-stroke ejection.

Never use full force at once.

✔ Manual Assistance:

Use brass or hardwood rods with a light hammer (0.5–1kg) when necessary.

Never strike mold surfaces with steel tools!

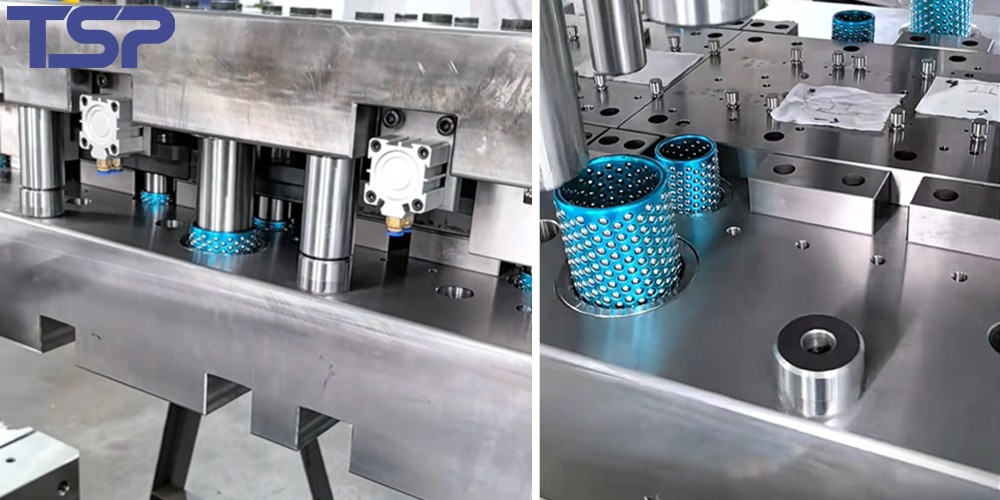

✔ Hydraulic Pullers & Induction Heaters:

Best for removing bushings, inserts, and press-fitted components.

Always ensure aligned force and avoid off-axis loads.

Induction heaters: Heat only the target part (typically under 250°C), reducing deformation risks.

✔ Torque Wrench for Bolt Removal & Assembly:

| Bolt Size | Recommended Torque (Nm) |

|---|---|

| M6 | 10 |

| M8 | 25 |

| M10 | 50 |

| M12 | 85 |

| M16 | 210 |

| M20 | 400 |

Always loosen bolts diagonally and gradually to release internal stress.

Calibrated torque wrenches must be used for reassembly—no more “feel-based tightening”!

📋 Principle 3: Disassembly Logic + Full Documentation = Flawless Reassembly

Precision molds are like complex watches. One wrong step in disassembly can make reassembly impossible.

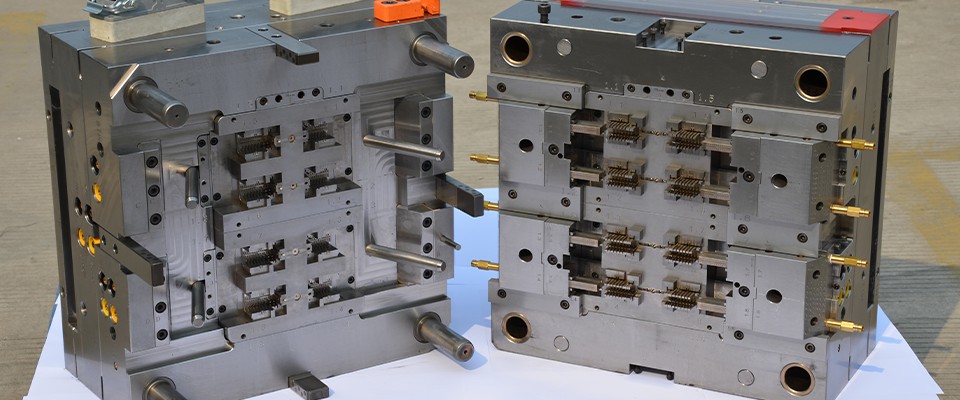

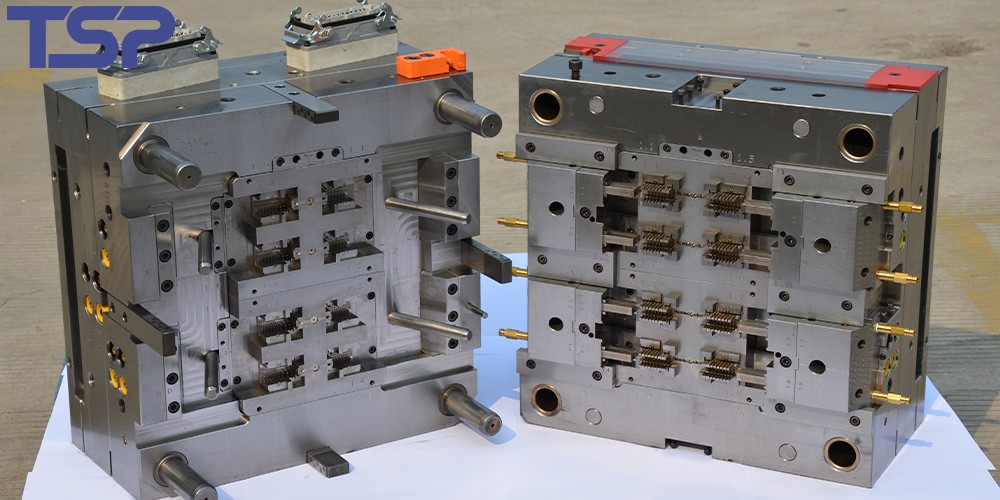

✔ Recommended Disassembly Order (Example: Injection Mold):

Remove external clamps and hardware.

Disengage side-action components (slides, angled pins, etc.).

Open mold—use soft-tipped pry bars at designated slots.

Remove ejector system (base plate, pins, etc.).

Remove cavity/core inserts.

Detach guide pins and alignment parts.

✔ Documentation Tools:

Photos & Videos: Capture every assembly stage.

Permanent Markings: Engrave or label each part clearly.

Checklists: Record wear, damage, or missing parts.

Sketches: Draw exploded views or part positions as needed.

💡 Final Thoughts: Gentle Disassembly is the Smartest Investment

Violent disassembly isn’t just outdated—it’s profit sabotage. The “3 Gentle Principles” ensure:

Higher product quality

Fewer defects and repairs

Less downtime

Extended mold life (10%+)

📊 One auto parts company reduced abnormal mold damage by 40% and saved $120,000 annually after adopting gentle disassembly protocols.

👉 Precision manufacturing deserves precision care. Start today—trade your hammer for a torque wrench, and make every disassembly a step toward longer mold life and leaner production.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone