On August 8, 2025, TSP Group Shanghai Tiantan Electronics Technology Co., Ltd. (hereinafter referred to as “Tiantan Electronics”) organized a specialized training session on Advanced Product Quality Planning (APQP). The aim was to deepen the team’s understanding of APQP, enhance cross-functional collaboration, and ensure that customer requirements are met throughout the entire product development process.

The event attracted over 50 in-person participants and more than 60 online attendees from project management, quality, production, and other departments. The training atmosphere was highly engaging and interactive.

Opening Remarks from the General Manager

APQP Is a Systematic Process — Everyone Must Deepen Their Understanding

At the start of the training, Mr. Qiu Yongfu, General Manager of Tiantan Electronics, noted that while APQP is a familiar topic, many teams still have a fragmented understanding of it. He emphasized the importance of building a comprehensive knowledge framework through systematic training, enabling employees to integrate APQP into the entire product lifecycle — transforming from beginners to true experts.

Expert Insights: Core Value of APQP and the Five Key Phases

The training covered:

Overview of APQP

The five phases and key deliverables

The six core automotive quality tools and their relationships

APQP implementation, success factors, and challenges

Integration of APQP with other quality management systems

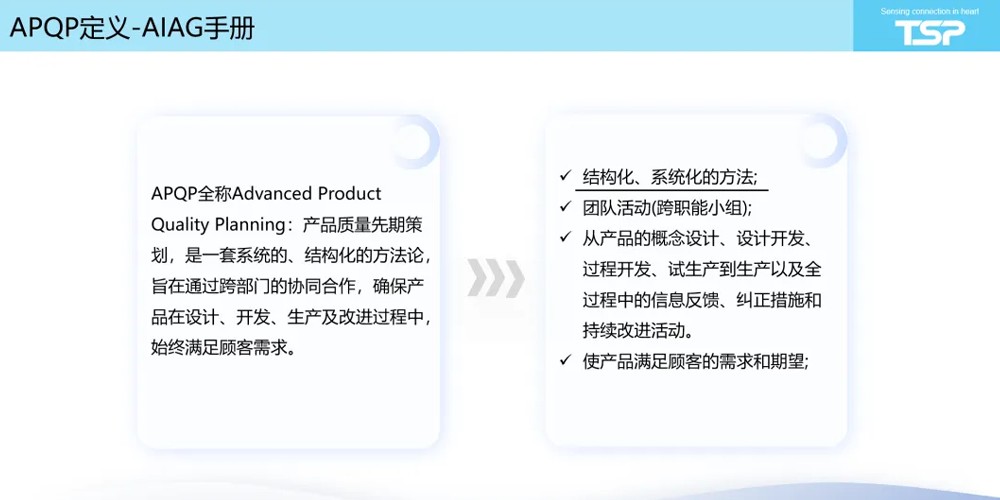

Mr. Zhang Cong, Senior Quality Manager, introduced APQP from the perspectives of concept, methodology, purpose, and value, stressing the “prevention-first” quality philosophy. Using real industry cases, he explained how APQP’s structured and systematic approach helps identify customer needs early, reduce costly late-stage changes, avoid development risks, lower quality costs, ensure product consistency, and achieve on-time delivery.

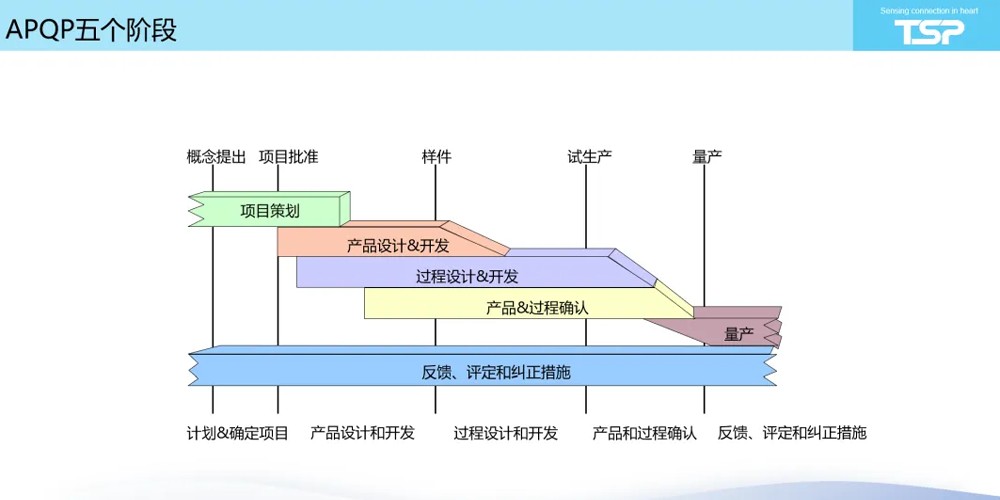

Following this, Ms. Zhao Jie, Senior Project Manager, systematically reviewed the five phases of APQP — Project Planning, Product Design & Development, Process Design & Development, Product & Process Validation, and Mass Production & Continuous Improvement. She shared practical project experiences, detailing the core outputs of each phase, common challenges, and relationships among key documents. Zhao emphasized that successful APQP execution requires deep cross-department collaboration, with all deliverables strictly closed-loop.

Later, Mr. Zhang outlined the five key success factors for APQP implementation:

Cross-functional team involvement

Clear understanding of requirements

Effective risk management

Efficient communication

Continuous improvement

The training also explored the interconnection between APQP and the Five Core Automotive Quality Tools (FMEA, Control Plan, PPAP, MSA, SPC) and its integration with IATF 16949, Six Sigma, and Lean Manufacturing.

APQP: A Proven Tool for the Automotive & Manufacturing Industries

As a widely used and mature methodology in automotive and manufacturing sectors, APQP ensures that every step from product design to mass production is customer-focused, achieving a balance between quality, cost, and delivery through cross-functional collaboration.

By combining theory with real-world case studies, this training provided participants with a practical APQP implementation guide that can be applied directly in daily work.

TSP Group will continue to promote the in-depth application of APQP and other core quality tools, solidifying its quality management system and delivering reliable, value-driven products for global customers.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone