At TSP, we stand at the forefront of precision tooling, molding, and stamping, with over 26 years of expertise in delivering large-scale connectivity and harness solutions. Our approach is centered around quality, innovation, and strong, collaborative relationships with our clients. Serving industries ranging from automotive and telecommunications to aerospace and med-tech, we are committed to engineering excellence and delivering solutions that meet the most demanding standards.

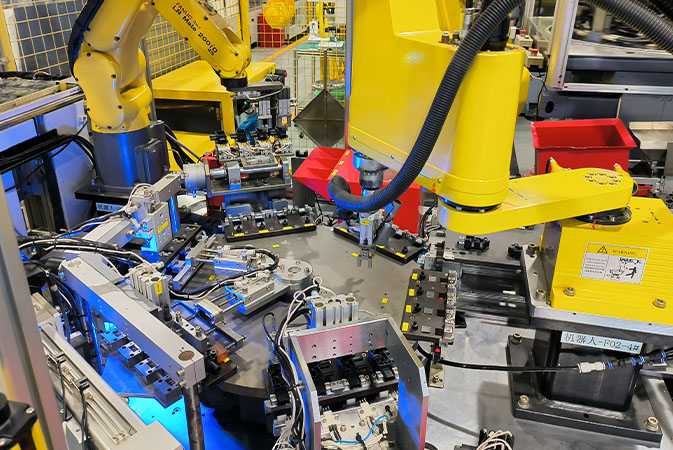

With a comprehensive range of capabilities, TSP supports your project through every phase of development. From engineering design to precision stamping and advanced molding techniques, our team brings unmatched technical expertise and state-of-the-art manufacturing facilities to every project.

TSP’s engineering team excels at transforming complex concepts into manufacturable products. Leveraging over two decades of experience, we ensure that each design is optimized for efficient, high-volume production, while maintaining the highest standards of quality and precision.

Improved cost efficiency, streamlined production, and reduced waste.

Mechanical systems, material optimization, and design validation.

Advanced CAD, 3D modeling, and prototyping.

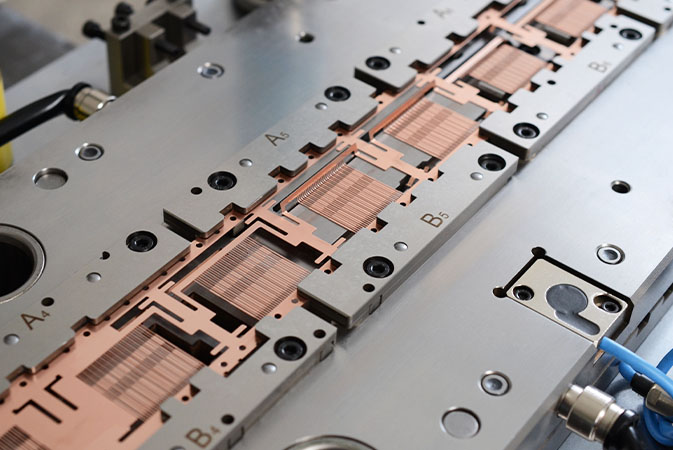

Our stamping services at TSP are designed to handle the most intricate and demanding specifications. With precision stamping expertise spanning over two decades, we deliver consistent, high-quality parts at scale for industries such as automotive, telecommunications, and aerospace.

High efficiency, lower material waste, and reduced production time.

Semiconductors, microelectronics, and telecommunications.

Ultra-fine tolerances, high reliability, and ideal for miniaturized components.

At TSP, our molding capabilities include insert molding, over molding, and two-shot molding. These advanced processes allow us to create products that combine multiple materials and properties, offering enhanced durability, functionality, and aesthetic appeal.

Increased strength, reduced assembly time, and cost efficiency.

Improved user experience, enhanced functionality, and aesthetic flexibility.

Greater design flexibility, multi-material components, and reduced post-processing.

At TSP, we maintain a relentless focus on quality. With more than 50,000 square meters of manufacturing space across facilities in Shanghai, Anhui, Mexico, and Morocco, we have the scale and capability to meet global demands. Our commitment to excellence is reinforced by our ISO certifications, and our processes undergo rigorous testing to ensure every product meets the highest industry standards.

At TSP, we believe in a smooth, collaborative approach that ensures the success of every project. Our process is designed to provide clarity and efficiency, from concept to completion.

We work with you to understand your specific requirements and project goals.

Our team develops optimized designs that ensure manufacturability at scale.

We produce prototypes for validation, ensuring your specifications are met before full-scale production.

Upon approval, we move into large-scale manufacturing with tight quality control.

We ensure timely delivery and offer ongoing support as your project evolves.

Brochure (PDF)

515, Huifa Road, Jiading Industrial Zone, Shanghai. E-Mail sales@tsp.cn

Copyright © TSP All Rights Reserved.