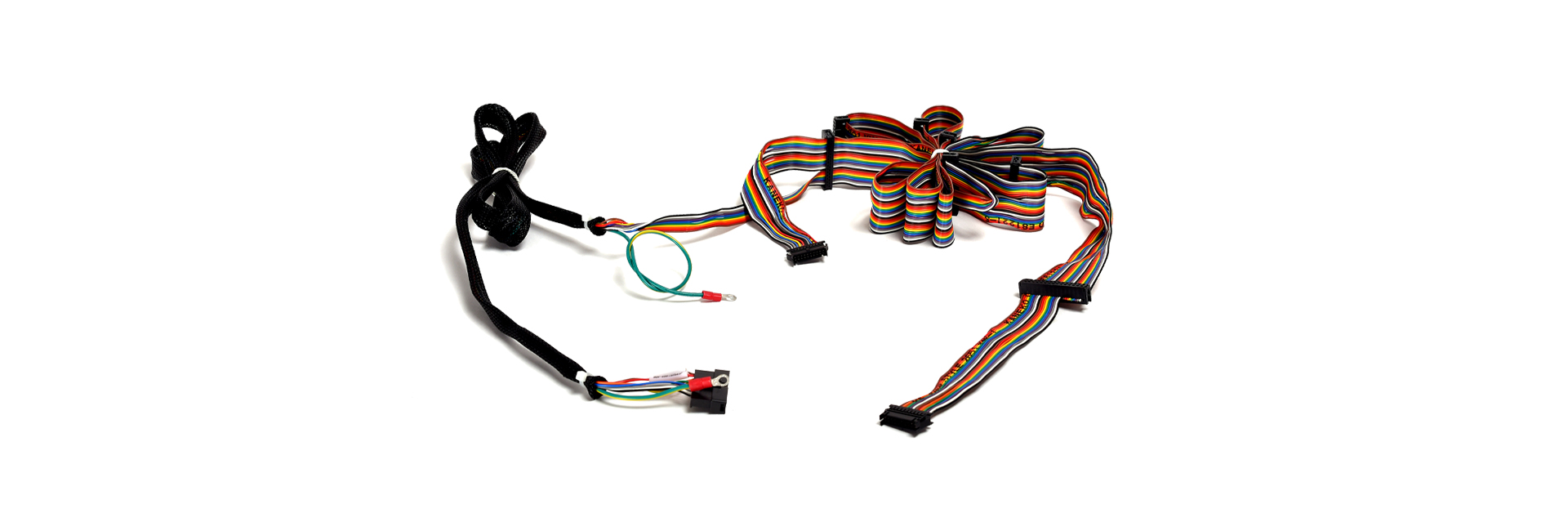

TSP specializes in the design and manufacturing of custom medical wiring harnesses to provide stable and reliable electrical connections for various medical devices. Our products are manufactured in strict accordance with international medical industry standards, ensuring they meet the high-quality and performance requirements of OEM manufacturers. We use certified components (wires, connectors, terminals, etc.) to ensure that each harness can perform safely, durably, and consistently in complex medical environments.

| Wiring Scheme | Rated Temperature | Rated Voltage | Connector | Flame Retardant Level | Standard |

|---|---|---|---|---|---|

| 28AWG (7/0.127TA) * 30C | 105℃ | 600V | Using JAE | VW-1 | Meet RoHS Standard |

| Wiring Scheme | Rated Temperature |

|---|---|

| Wiring Scheme | 28AWG (7/0.127TA) * 30C |

| Rated Temperature | 105℃ |

| Rated Voltage | 600V |

| Connector | Using JAE |

| Flame Retardant Level | VW-1 |

| Standard | Meet RoHS Standard |

● Usage:Industrial Automation

Supports reliable communication between the robot arm and the control system, enabling efficient operation of automation tasks.

● Usage:Industrial Automation System

Wiring harness for frequency conversion cabinets, providing strong connections to enhance efficiency and safety in industrial settings.

● Usage:Emission Control Systems

High-performance connector designed to enhance the efficiency of emission reduction systems, ensuring reliable operation and compliance with environmental standards.

The lifespan of a connector typically depends on the usage environment and frequency of use. Generally, high-quality connectors can withstand thousands of insertion and removal cycles under normal conditions.

When selecting a connector, consider the following factors:

• Application environment: temperature, humidity, vibration, etc.

• Electrical requirements: necessary voltage, current, and impedance.

• Size and shape: ensure compatibility with existing equipment.

Installation steps typically include:

• Ensure the power is turned off.

• Align the connector, ensuring the pins on the plug and socket fit correctly.

• Apply even pressure to insert until you hear a “click,” indicating it is locked in place.

If you experience poor contact, try the following:

• Check if the connector is securely inserted.

• Clean the contact surfaces to remove dust and debris.

• Inspect the connector for damage; if damaged, replace it.

Many connectors are designed to be waterproof and weather-resistant, but for outdoor use, it’s best to select connectors specifically designed for such environments, ensuring they meet the required protection ratings.

We provide customization services for connectors, including special sizes, materials, and electrical specifications. Please contact our technical support for more information.

To extend the lifespan of connectors, we recommend regularly checking and cleaning them. Avoid storing them in high-temperature or humid environments, and refrain from excessive pulling on cables during use.

If you have any questions, feedback, or need more information, please fill out the form below. Our customer service team will get back to you as soon as possible. Thank you for your support!