With its 12 mm metric thread and screw-lock mechanism, the M12 connector ensures secure and vibration-resistant connections for sensors, actuators, and field devices.

Our M12 series is manufactured from nickel-plated brass or PA66 plastic with gold-plated copper alloy contacts, providing excellent conductivity, corrosion resistance, and long service life.

Fully compliant with IEC 61076-2-101, it supports multiple pin counts and coding types, ensuring perfect compatibility with industrial and medical equipment worldwide.

| Thread Type | Pin Configuration | Rated Current | Rated Voltage |

|---|---|---|---|

| M12 × 1 metric screw-locking | 3-pin / 4-pin / 5-pin / 8-pin (A-code, D-code, X-code optional) | 4 A max (per contact) | 60 V AC/DC (signal type) |

| Wire Insulator Material | FEP / PVC |

|---|---|

| Thread Type | M12 × 1 metric screw-locking |

| Pin Configuration | 3-pin / 4-pin / 5-pin / 8-pin (A-code, D-code, X-code optional) |

| Rated Current | 4 A max (per contact) |

| Rated Voltage | 60 V AC/DC (signal type) |

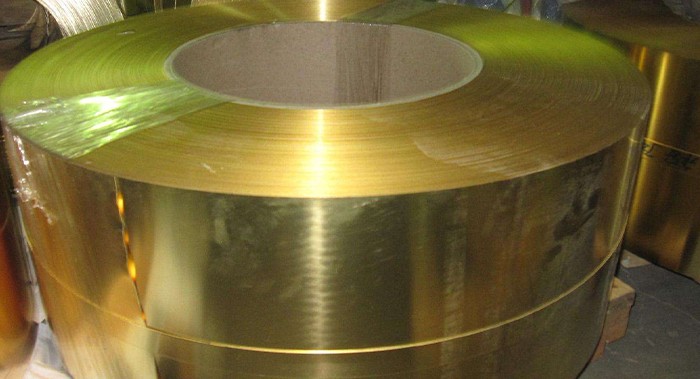

TSP uses top-grade international 59-1 brass (instrument-grade),

featuring high copper content, excellent hardness, and low impurities.

This ensures stable current transmission and minimal signal loss.

All plastic pellets are made from new, medical-grade materials.

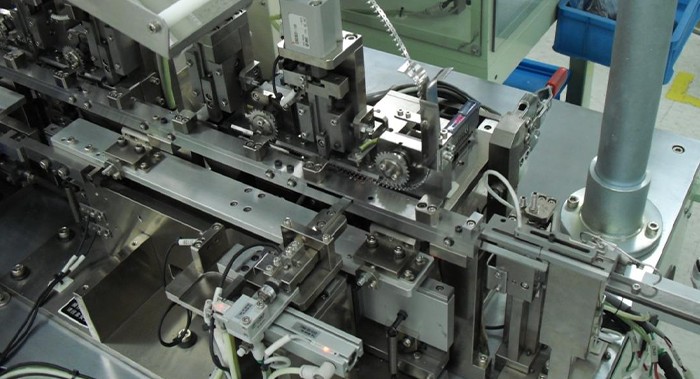

With 21 imported high-speed stamping machines,

TSP forms connector pins in one process and eliminates

any twisted, cracked, or deformed parts to guarantee precision.

Products undergo a 5-layer electroplating process

on a 65-meter automatic line, ensuring durability

under 260–280°C heat and 24-hour salt spray testing.

Using 35 precision molding machines and imported PET resin,

TSP ensures superior insulation, high-temperature resistance,

and export-grade injection quality.

Automated assembly machines ensure precise component fitting,

rejecting defective units and maintaining perfect appearance

and performance consistency.

Each connector undergoes individual inspection and

comprehensive reliability tests (salt spray, 280°C heat, etc.),

guaranteeing flawless quality.

● Usage:Optical communication systems

Adopts a durable plastic housing with precise alignment for optimal optical coupling and easy installation on PCBs or optical devices.

● Usage:Medical imaging systems (ultrasound, CT, X-ray, MRI modules)

Housing is made of high-temperature LCP material and the terminals are gold-plated for superior conductivity and corrosion resistance.

● Usage:Monitoring

Designed to withstand extreme temperatures up to 300°C, ensuring safety and efficiency in critical applications.

The lifespan of a connector typically depends on the usage environment and frequency of use. Generally, high-quality connectors can withstand thousands of insertion and removal cycles under normal conditions.

When selecting a connector, consider the following factors:

• Application environment: temperature, humidity, vibration, etc.

• Electrical requirements: necessary voltage, current, and impedance.

• Size and shape: ensure compatibility with existing equipment.

Installation steps typically include:

• Ensure the power is turned off.

• Align the connector, ensuring the pins on the plug and socket fit correctly.

• Apply even pressure to insert until you hear a “click,” indicating it is locked in place.

If you experience poor contact, try the following:

• Check if the connector is securely inserted.

• Clean the contact surfaces to remove dust and debris.

• Inspect the connector for damage; if damaged, replace it.

Many connectors are designed to be waterproof and weather-resistant, but for outdoor use, it’s best to select connectors specifically designed for such environments, ensuring they meet the required protection ratings.

We provide customization services for connectors, including special sizes, materials, and electrical specifications. Please contact our technical support for more information.

To extend the lifespan of connectors, we recommend regularly checking and cleaning them. Avoid storing them in high-temperature or humid environments, and refrain from excessive pulling on cables during use.

If you have any questions, feedback, or need more information, please fill out the form below. Our customer service team will get back to you as soon as possible. Thank you for your support!