In the fast-paced world of modern manufacturing, precision metal stamping plays a critical role in delivering high-volume, high-accuracy components for industries like automotive, electronics, medical, and energy. As a precision mold and wire harness manufacturer also offering stamping services, we often find that many engineers and sourcing teams are unsure about how to choose the right stamping partner or process. This guide explains the fundamentals of metal stamping — from material selection to tooling — to help you make better decisions.

1. What is Precision Metal Stamping?

Precision metal stamping is a cold-forming process that uses high-tonnage presses and custom dies to shape flat sheet metal into specific parts or features. Unlike traditional machining, stamping is ideal for high-volume production with tight tolerances and repeatable consistency.

Depending on your part design and function, the stamping process can include:

Blanking – cutting out the base part shape

Bending – forming parts at specific angles

Coining – compressing material to create fine features

Embossing – raising or recessing designs

Drawing – forming 3D shapes from flat stock

2. Key Process Types: Progressive vs. Transfer Die Stamping

When selecting a stamping method, two common options arise:

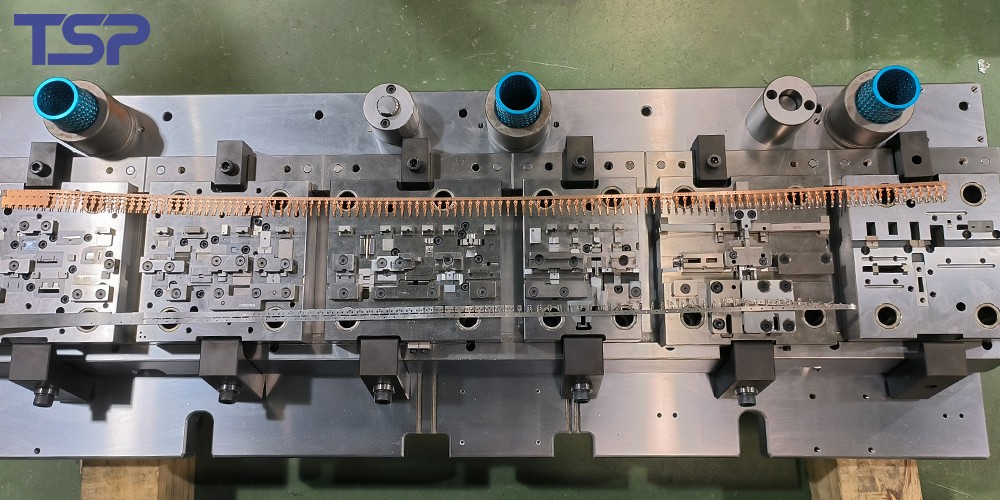

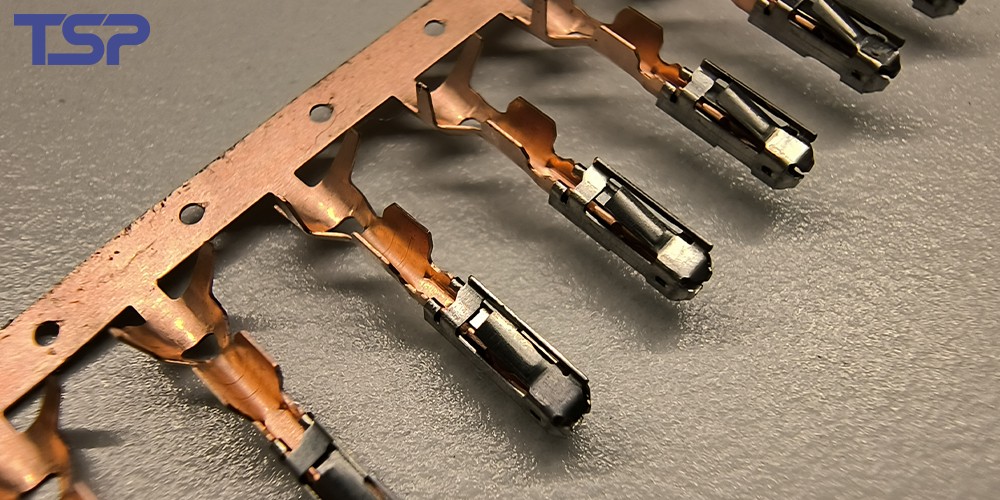

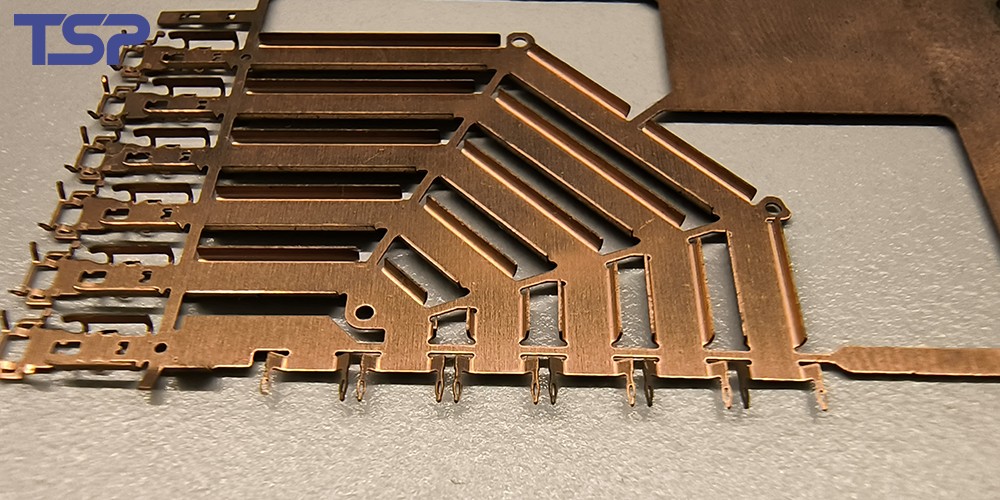

Progressive Die Stamping: The metal strip moves through a series of dies, each performing a unique operation. Ideal for small-to-medium parts with complex geometries.

Transfer Die Stamping: Each operation is performed in separate dies, and the part is physically moved between stations. Preferred for larger, deeper-drawn parts like automotive structures.

At our facility, we evaluate your product geometry, annual volume, and material thickness to recommend the most cost-effective method.

3. Material Selection: The Foundation of Stamping Success

Choosing the right material is essential. The wrong alloy can lead to cracking, poor formability, or excessive die wear.

Commonly used materials include:

| Material Type | Properties | Common Use Cases |

|---|---|---|

| Stainless Steel | Corrosion-resistant, strong | Medical devices, connectors |

| Copper Alloys | Conductive, ductile | Electrical contacts, terminals |

| Aluminum Alloys | Lightweight, corrosion-resistant | Automotive brackets, housings |

| Cold-Rolled Steel | Cost-effective, strong | Structural frames, enclosures |

We help our customers optimize material choices based on tensile strength, elongation, grain direction, and forming index.

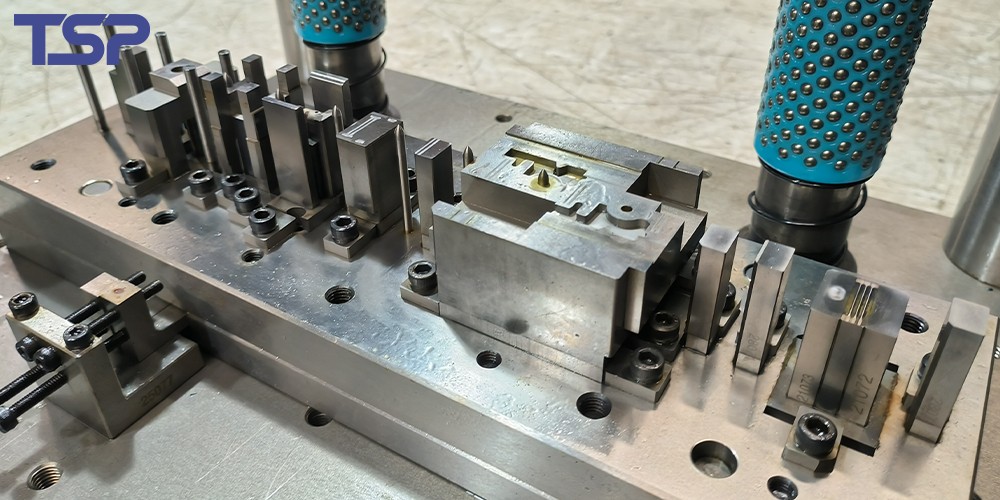

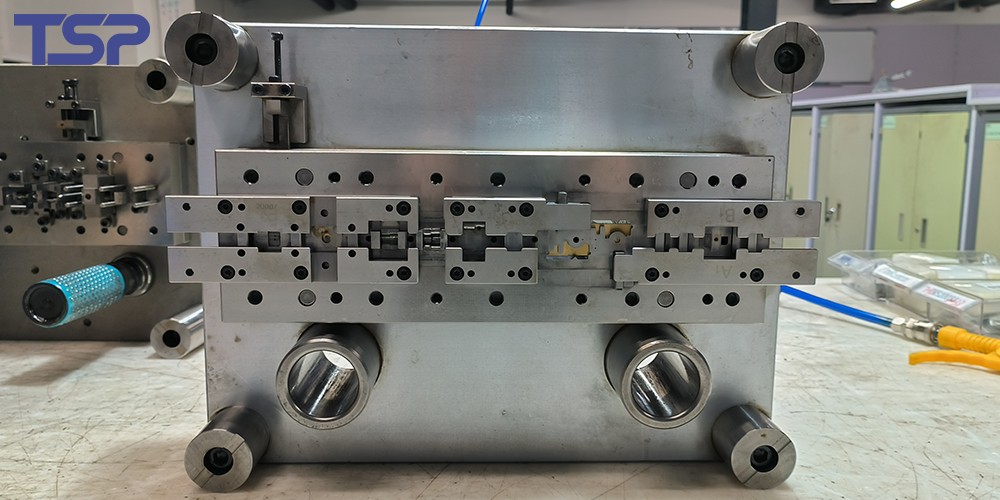

4. Tooling: Where Precision Starts

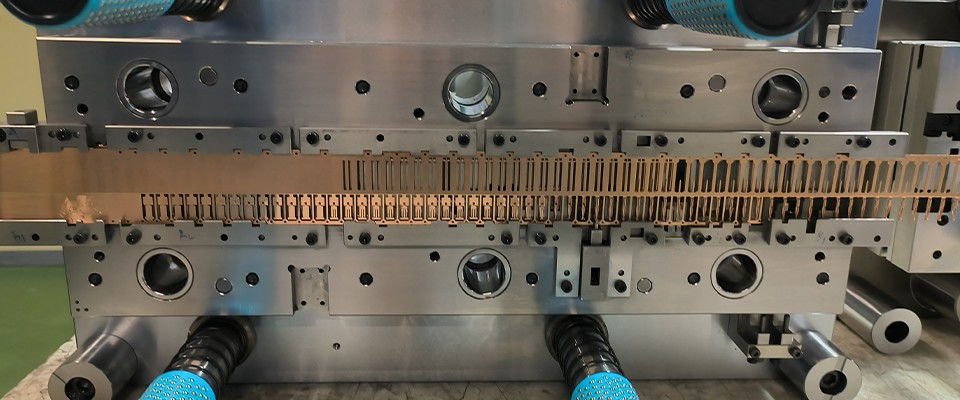

High-quality tooling is the backbone of precision stamping. At our mold workshop, we design and manufacture custom progressive and transfer dies in-house, ensuring:

Consistent part accuracy over millions of cycles

Minimal downtime for maintenance or adjustments

Integration with secondary operations like tapping or inserting

We use advanced EDM, CNC machining, and CMM inspection to ensure your dies are built to last and perform at peak precision.

5. Quality, Tolerances & Inspection

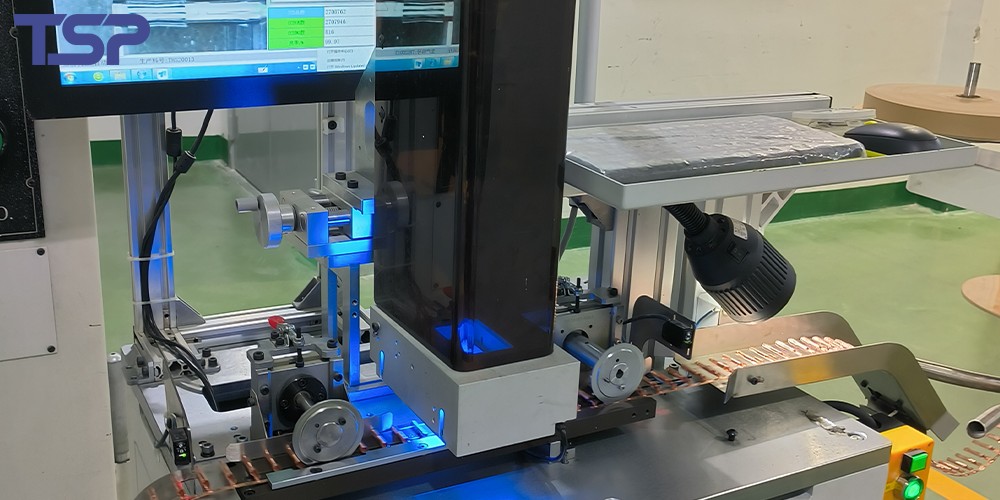

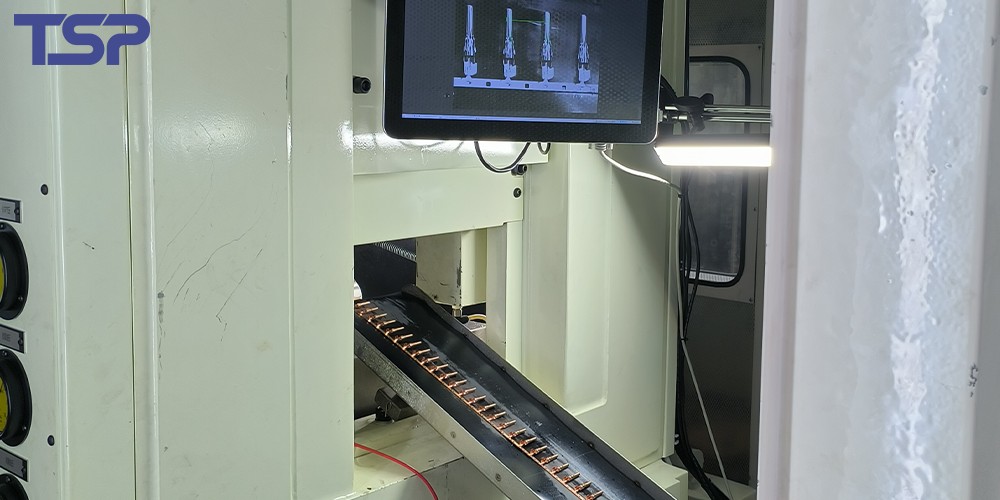

Precision stamping demands tight tolerances, often within ±0.01 mm. Our stamping lines are supported by:

Inline vision inspection systems

Automated part sorting

Full PPAP and FAI documentation for automotive and aerospace clients

You can trust every batch we deliver to meet your functional and regulatory requirements.

6. Why Combine Stamping with Wire Harness and Mold Capabilities?

When you work with us, you don’t just get stamped parts — you gain a vertically integrated partner that can also:

Design and build custom connector housings (injection molds)

Manufacture precision wire harnesses for your assembly

Deliver plug-and-play subassemblies directly to your line

This reduces supplier risk, shortens lead times, and ensures seamless compatibility between metal, plastic, and wire components.

Conclusion

Precision metal stamping is not just about pressing metal — it’s about engineering, consistency, and total cost efficiency. Whether you’re sourcing high-volume terminals, precision shielding, or custom metal brackets, we’re here to help from design consultation through to mass production.

If you’re ready to take your stamped components to the next level — with full mold, wire harness, and quality control capabilities — contact us today and let’s talk about your next project.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone