Insert molding is an advanced injection molding process where one or more pre-formed components (inserts) are placed into a mold, and molten plastic is injected to form a unified part. These inserts are typically made of metal but can also include wires, sensors, ceramics, or other plastics. This technique enables the creation of strong, lightweight, and functionally integrated parts, making it an ideal choice for industries requiring mechanical strength, electrical conductivity, and design flexibility.

1. What is Insert Molding?

Insert molding involves placing an insert into the cavity of an injection mold, after which plastic is injected to encapsulate the insert, creating a single, solid part. Unlike overmolding, which typically involves two sequential molding operations, insert molding completes the entire process in one molding cycle.

Types of insert placement:

Manual placement: Suitable for small production volumes or complex, low-run parts.

Automated placement: Common in mass production for consistency, faster cycles, and reduced labor costs.

2. Advantages of Insert Molding

Mechanical Performance: Combines the strength of metals with the flexibility and insulation of plastics.

Improved Durability: Enhances wear resistance, vibration resistance, and bonding strength.

Design Integration: Allows the production of compact, multifunctional assemblies without the need for secondary processes.

Assembly Reduction: Reduces or eliminates the need for adhesives, screws, soldering, or welding.

Flexible Material Use: Can embed not only metals but also wires, fabric, glass, coils, and more.

Weight & Size Savings: Offers a way to shrink the product footprint by consolidating parts.

Enhanced Sealing: Ideal for sealing fragile inserts such as glass or coils within the plastic.

Automation Ready: Works seamlessly with vertical injection molding machines and robotic arms.

3. Disadvantages of Insert Molding

Complex Mold Design: Accommodating inserts often increases mold complexity and cost.

Thermal Expansion Mismatch: Differences between plastic and metal inserts may cause internal stress, leading to warping or cracking.

Insert Handling: Incorrect placement or movement during injection can result in misalignment or defects.

Scrap Risk: Defects in molding or insert placement often lead to complete part rejection.

Reduced Recyclability: Integrated components are difficult to separate for recycling.

Preprocessing Requirements: Some inserts require drying, preheating, or surface preparation for optimal adhesion.

4. Applications of Insert Molding

Insert molding is widely used in industries such as:

Automotive: Sensor housings, threaded mounts, wire harness connectors.

Medical Devices: Surgical instruments, diagnostic equipment, implants.

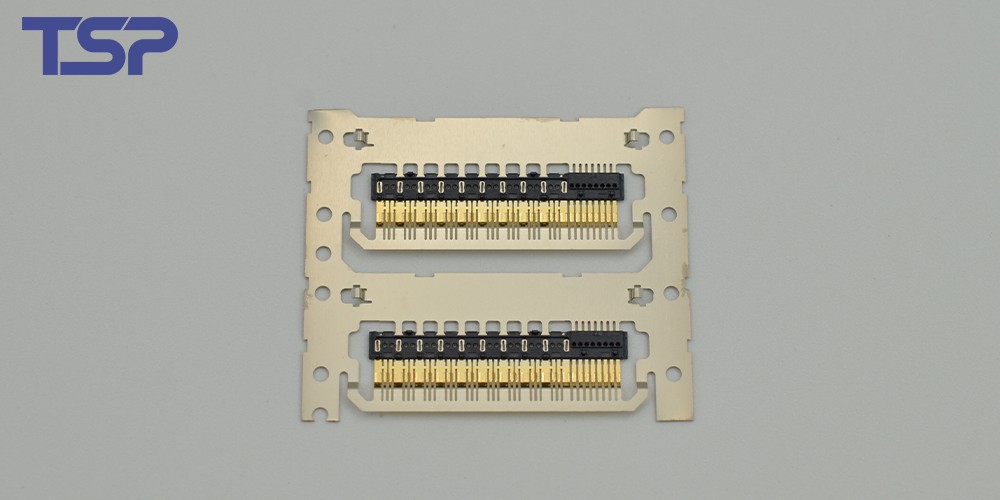

Electronics: Circuit boards, terminal blocks, USB connectors.

Consumer Products: Knobs, handles, multi-material buttons.

This process is especially valuable in products that must endure mechanical stress or combine multiple materials in compact forms.

5. Insert Molding Design Guide

To ensure successful insert molding, both the product and the insert must be designed with manufacturability in mind (DFM principles):

5.1 Insert Material Selection:

Common materials: brass, stainless steel, aluminum, copper.

Inserts must resist corrosion and support good plastic adhesion.

5.2 Insert Geometry & Anchoring:

Round/cylindrical shapes are preferred for ease of mold cavity design.

Use knurling, flanges, grooves, undercuts, or holes to increase mechanical locking.

Avoid sharp edges that create stress concentration.

5.3 Insert Placement & Clearance:

Inserts should be centered and held securely to avoid displacement.

Maintain sufficient wall thickness between insert and mold surfaces.

Provide minimum clearance to prevent sink marks and voids.

5.4 Molding Tolerances:

Ensure inserts are dimensionally consistent.

Add lead-ins or chamfers for easy insert fitting.

5.5 Mold Design Considerations:

Provide features like nesting pockets, locator pins, and ejector systems.

Venting must be included around inserts to prevent gas traps.

5.6 Specialized Insert Types:

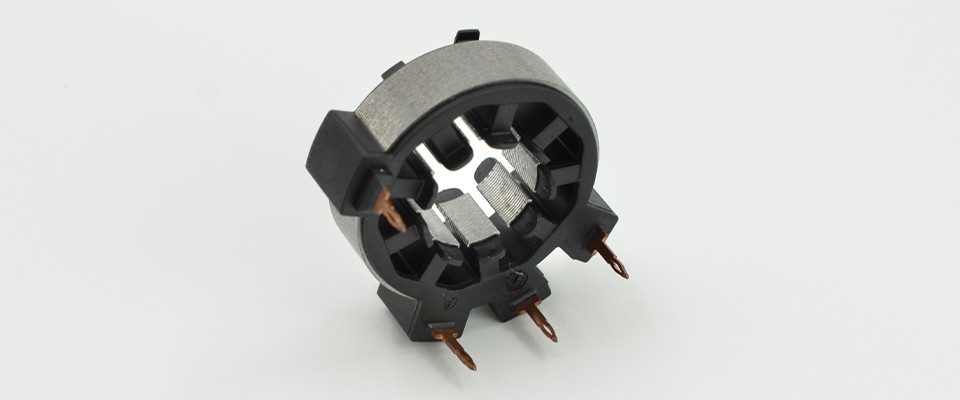

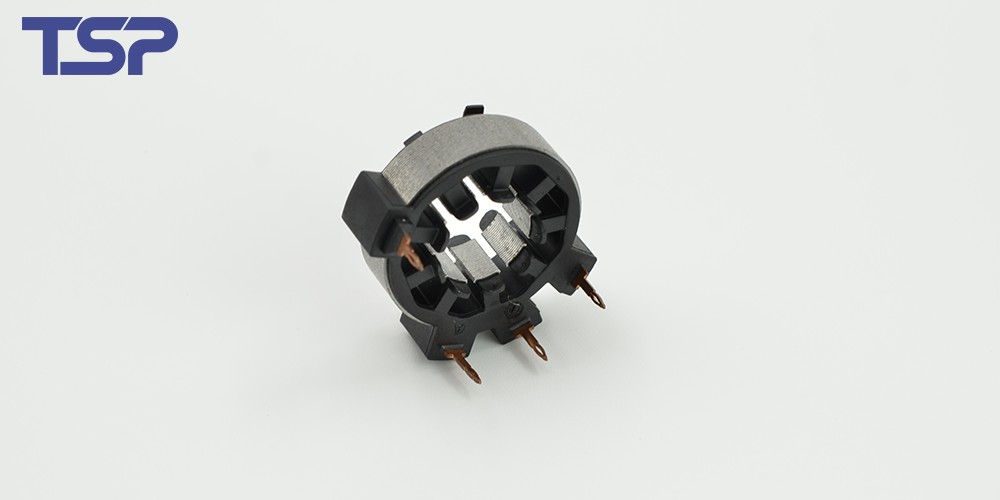

Threaded inserts: Common in electronic housings and mounts.

Terminal inserts: Used in wire harnesses and connectors.

Sheet or flat inserts: May include pre-punched holes or textured surfaces.

5.7 Automation Compatibility:

Inserts must be shaped for robotic gripping and orientation.

Tolerances should allow consistent loading by automation equipment.

6. Why Choose Us as Your Insert Molding Partner

As a precision mold and custom wire harness manufacturer, we specialize in high-performance insert molding for industries demanding tight tolerances and durability. Our strengths include:

In-house mold design and fabrication for insert-specific projects

Support for both manual and automated insert placement

Experience with complex multi-insert parts for medical and automotive applications

Strict quality control and ISO-certified production

We can turn your concept into a high-quality molded part that integrates function, aesthetics, and performance — all in one step.

7. Get in Touch

Looking for a trusted partner to bring your insert molding project to life? Contact us today to discuss your needs and get a fast, customized quote.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone