Choosing the right jacket material is one of the most important decisions in wire harness design. The jacket directly affects durability, flexibility, temperature resistance, chemical protection and long-term reliability — especially in industries such as automotive, robotics, energy storage, medical devices and industrial automation.

This guide summarizes the key performance differences between PVC, XLPE and PTFE and provides practical engineering recommendations based on TSP’s experience in precision wire harness manufacturing.

PVC Jacket Characteristics and Uses

Best for: general industrial equipment, automotive low-voltage wiring, home appliances, office equipment

PVC (Polyvinyl Chloride) is the most widely used jacket material thanks to its versatility and cost efficiency.

Advantages

Low cost and easy to process

Good flexibility

Natural flame retardancy

Good electrical insulation

Wide color options for circuit identification

Suitable environments

Stable indoor temperatures, moderate mechanical stress, budget-driven projects.

Limitations

Not ideal for high temperatures, aggressive chemicals or continuous dynamic bending.

XLPE Jacket Performance and Advantages

Best for: EV battery packs, high-temperature environments, industrial machinery, power wiring

XLPE (Cross-Linked Polyethylene) is engineered for enhanced thermal and mechanical performance.

Advantages

Higher temperature resistance (90–125°C)

Strong abrasion and cut resistance

Excellent insulation strength

Superior aging and UV resistance

Longer service life

Suitable environments

Battery systems, power circuits, industrial automation, outdoor applications.

PTFE Jacket High-Performance Capabilities

Best for: robotics, medical devices, aerospace electronics, extreme environments

PTFE (Polytetrafluoroethylene, Teflon) is a premium engineering material used when reliability and environmental resistance are critical.

Advantages

Exceptional temperature resistance (up to 200°C+)

Outstanding chemical corrosion resistance

Very low friction, ideal for repeated bending

High dielectric strength for high-speed signal clarity

Suitable environments

Robotic joints, medical probes, high-temperature chambers, corrosive environments, aerospace systems.

Limitations

Higher cost and more complex processing requirements.

Comparison at a Glance

| Performance | PVC | XLPE | PTFE |

|---|---|---|---|

| Cost | Low | Medium | High |

| Temperature Resistance | Moderate (70–105°C) | High (90–125°C) | Extreme (200°C+) |

| Flexibility | Good | Good | Excellent |

| Chemical Resistance | Basic | Good | Exceptional |

| Service Life | Medium | Long | Very Long |

| Typical Use | General industrial, automotive | EV battery, automation | Robotics, medical, aerospace |

How to Choose the Right Jacket Material

Here are practical recommendations based on TSP’s global engineering and OEM/ODM project experience:

● When you need the best cost-performance balance → Choose PVC

General electronics, office equipment, low-voltage automotive wiring.

● When you need both durability and higher temperature resistance → Choose XLPE

Power harnesses, battery systems, charging systems, industrial machinery.

● When you need maximum reliability and extreme resistance → Choose PTFE

Robotics, medical devices, aerospace, or highly dynamic cable chains.

Why Leading Companies Trust TSP for Wiring Harness Manufacturing

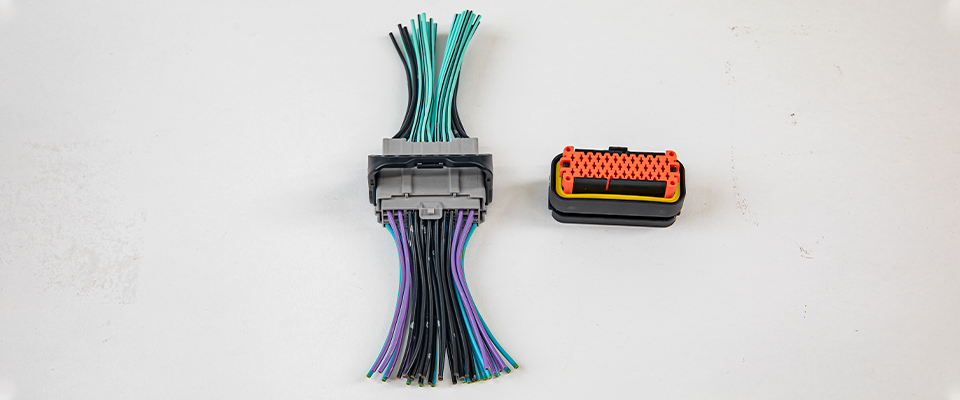

TSP is a global manufacturer of precision wire harnesses, cable assemblies, injection-molded components and custom connectors with facilities in China, Mexico and Morocco.

What makes TSP different:

Certified with IATF16949, ISO9001, ISO13485

Expertise in automotive, medical, energy storage, robotics and industrial control

Full range of jacket materials: PVC, XLPE, TPE, silicone, PTFE and others

In-house precision mold making and overmolding capabilities

Automated production and 100% electrical testing

Engineering support including 2D/3D design, FA testing and prototype development

Trusted by major global automotive Tier-1s, robotics brands and medical manufacturers

Need Help Choosing the Right Jacket Material?

TSP provides engineering consultation, custom design, material selection support and sample evaluation to help you build a safer, more durable and more competitive wiring harness solution.

Contact TSP today — your project deserves reliable, long-life wiring solutions.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone