Introduction: Perfect Match Between Materials and Molds is Key

In modern manufacturing, injection molding has become an indispensable production process across automotive, industrial control, home appliances, and medical sectors. However, different plastic materials have significant differences in physical properties, processing performance, and application environments, directly influencing mold design, manufacturing precision, production efficiency, and service life.

With years of experience in high-precision mold manufacturing and a global production layout, TSP provides a one-stop solution from material selection to mold delivery, ensuring each product is stable, reliable, and compliant with industry standards.

Step 1: Define Function and Application Requirements

Each type of injection molded product has specific functional and performance requirements:

Transparent Parts (e.g., light covers, display panels)

Recommended Materials: PMMA, PC

Mold Design Considerations: high-gloss mirror polishing, appropriate draft angles

Technical Notes: Ensure bubble-free, weld-line-free molding with high optical transparency

High-Temperature Components (e.g., engine bay parts, industrial sensor housings)

Recommended Materials: PBT, PA66, PEI

Mold Design Considerations: high-hardness mold steels, optimized cooling channels

Technical Notes: High heat deflection temperature and long-term thermal stability

High-Strength Structural Parts (e.g., industrial connector housings, medical device brackets)

Recommended Materials: Glass-fiber reinforced Nylon, PA66-GF30/50

Mold Design Considerations: optimized gate layout and venting system

Technical Notes: Impact resistance, wear resistance, high dimensional accuracy

Step 2: Consider Environmental Adaptability

The performance of molded parts in different environments affects material and mold selection:

Outdoor Applications: UV, humidity, extreme temperature variations

Recommendation: UV-resistant, aging-resistant materials, with surface coatings or UV stabilizers

Electronics and Electrical Fields: Fire resistance and flame retardancy

Requirement: UL94 flame-retardant materials, high flowability for complex cavities

Medical and Food Industries: Regulatory compliance

Materials must meet FDA or EU food contact standards; mold surface treatment must be non-toxic

Combining material selection with mold process design can significantly extend product life, reduce maintenance costs, and ensure compliance.

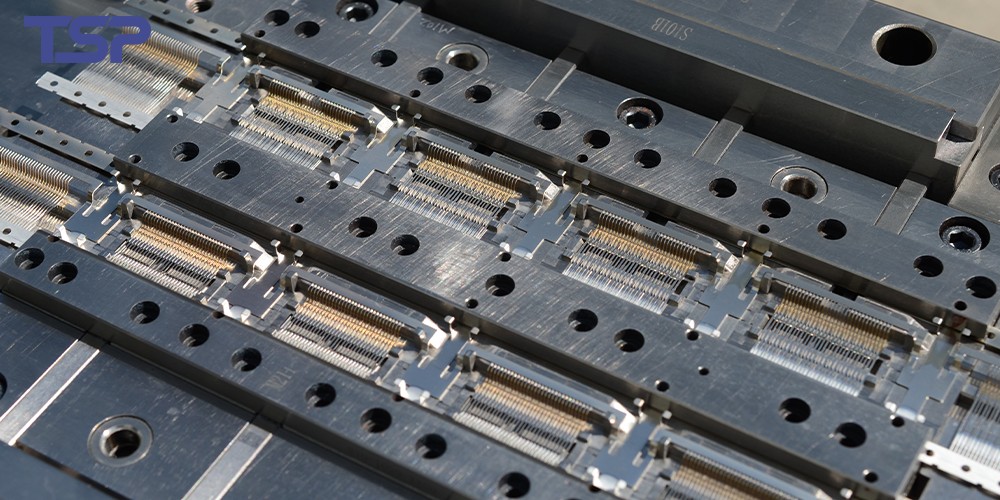

Step 3: Match Material Flowability with Mold Structure

Complex structures, thin-walled parts, and multi-cavity components require high flowability and precise mold design:

Thin-Walled Parts: low shrinkage, high flowability materials such as LCP or PC/ABS

Multi-Cavity Components: balanced runner system and gate layout

Long and Narrow Cavities: proper cooling and venting to avoid short shots and warpage

Using Moldflow simulation and CAD/Pro-E modeling, flow, filling, and shrinkage can be predicted before mold opening, reducing trial costs.

Step 4: Ensure Aesthetic and Surface Quality

The visual effect of a product directly impacts brand image:

High-Gloss Parts

Mold requires mirror polishing, with controlled injection pressure and temperature

Matte or Textured Parts

Achieved via mold etching or sandblasting, no extra coating required

Color Consistency

Select color-stable, easily pigmented materials and maintain constant molding temperature

TSP’s precision polishing and surface treatment technology ensure high-end parts meet international quality standards.

Step 5: Balance Cost and Production Volume

Different production scales require different material and mold strategies:

Small Batch, High Precision Products

Aluminum or soft steel molds reduce initial investment

Large Volume, Long-Term Production

High-hardness steels (e.g., H13, S136) reduce per-piece cost

Environmental and Regulatory Considerations

Biodegradable or recycled materials (PLA, PCR)

Compliance with medical, food, and electronic standards

Scientific cost evaluation allows clients to achieve economical production while ensuring quality.

TSP Professional Advantage: One-Stop Service from Material Selection to Delivery

Material Selection & Moldflow Analysis

Use CAD/Pro-E design and Moldflow simulation to predict flow, fill, and shrinkage

Global Production Layout

Manufacturing bases in Mexico and Morocco, technical support centers in Europe and the U.S., enabling rapid response

Full-Chain Quality Control

Including steel inspection, mold precision verification, and product dimensional & performance testing

Multi-Industry Experience

Covering automotive, industrial control, medical devices, consumer electronics, etc.

Continuous Innovation

Providing environmentally friendly material solutions and advanced precision injection molding technology

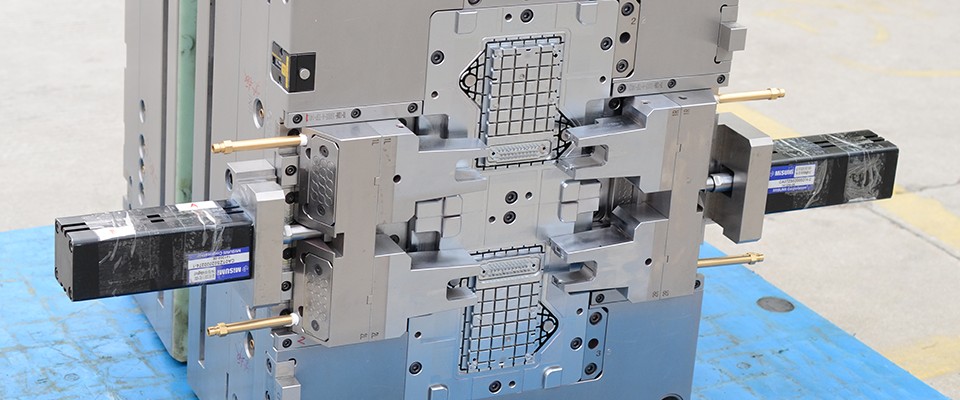

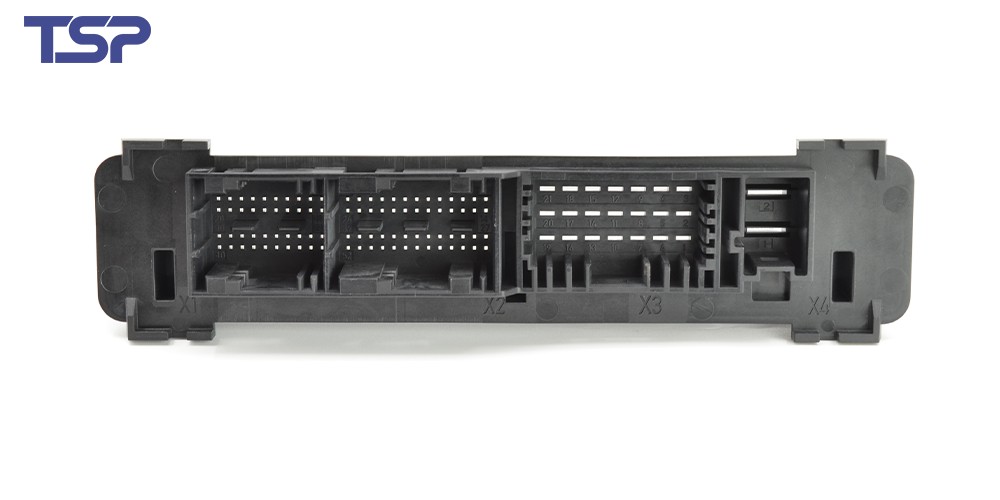

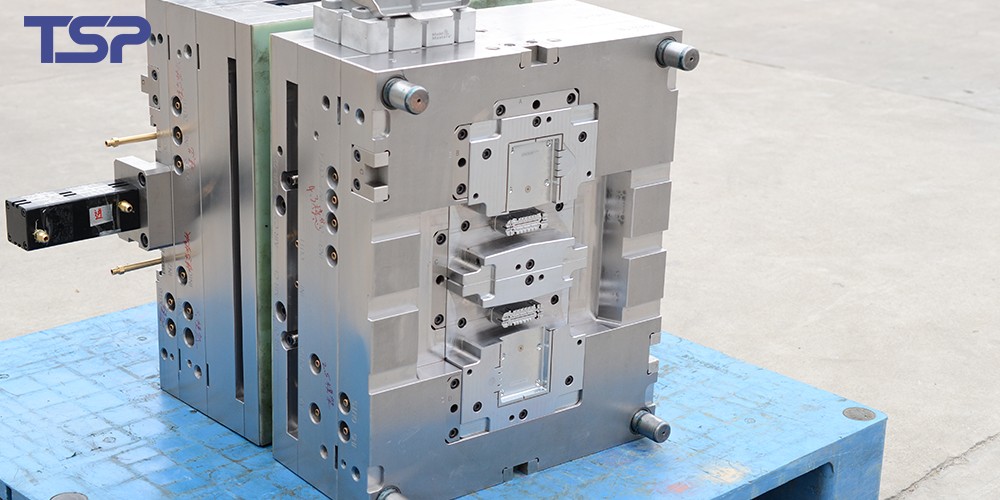

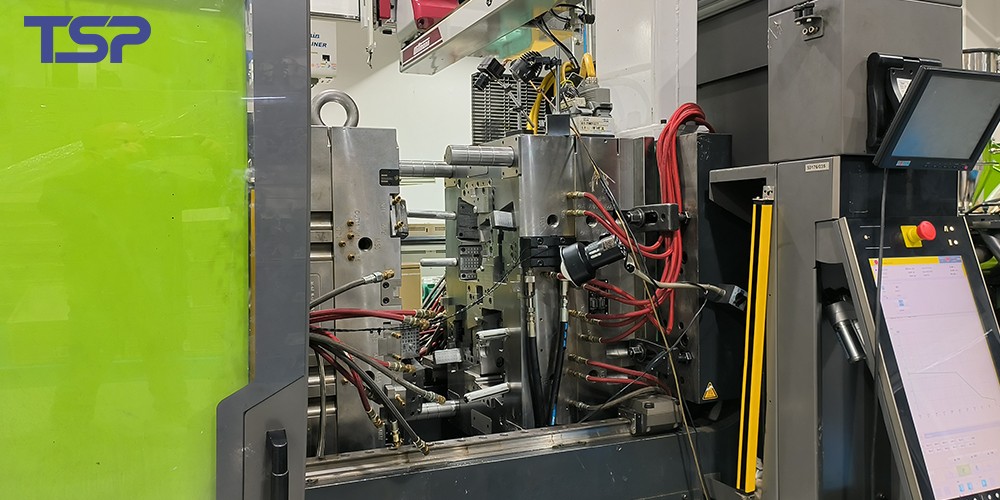

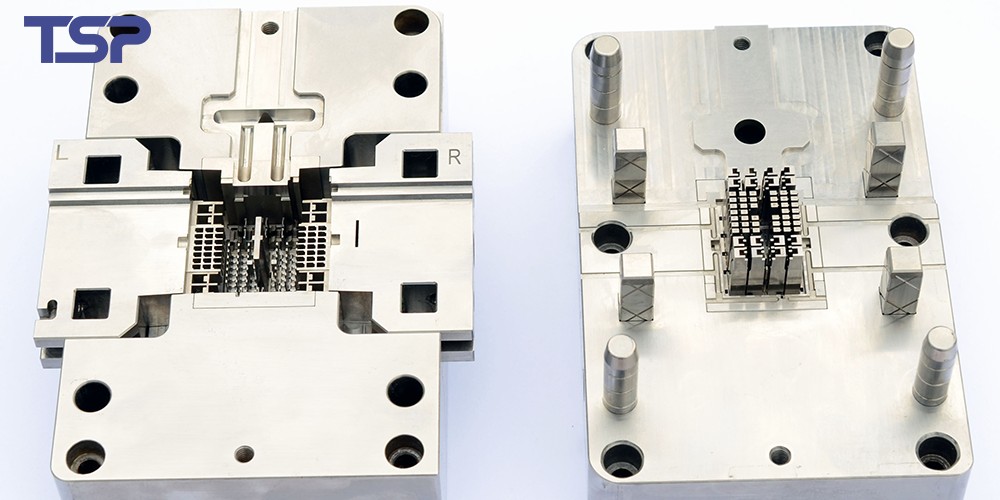

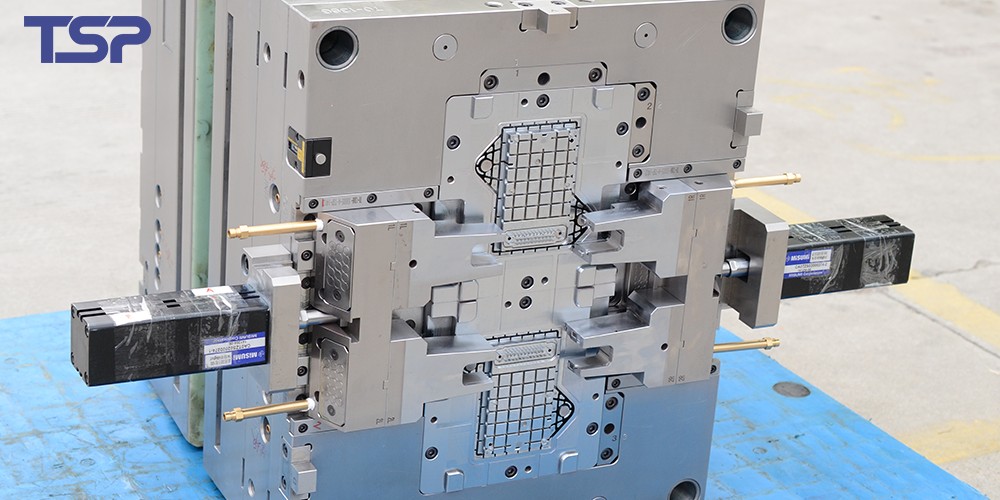

Case Study: Precision Industrial Connector Housing

Material: PA66-GF30

Structure: Multi-cavity terminal block housing

Design Challenges: Thin-walled, high precision, warp resistance, consistent surface texture

Solution: Optimized gate design, balanced cooling, Moldflow simulation verification

Result: Stable mass production, dimensional deviation ±0.05mm, 100% client satisfaction

Conclusion: Accurate Material Selection and Mold Matching Achieve Superior Quality

Choosing the right material and pairing it with the appropriate mold is essential for enhancing product competitiveness. TSP continues to provide high-quality, sustainable injection molds and plastic components with a global perspective, precision manufacturing, and innovative design.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone