With the rapid development of 5G and next-generation communication technologies, communication equipment is evolving towards higher frequencies and smaller sizes. Industry analysis indicates that the global 5G communication equipment market is expanding, and the signal loss rate for high-frequency transmission must be strictly controlled to extremely low levels (e.g., below 0.5dB/m). However, traditional wiring technologies face limitations in size and signal interference, making it difficult to meet the demands of miniaturized devices. Against this backdrop, TSP’s precision wiring technology, through innovative materials and design processes, has become the key to solving industry pain points.

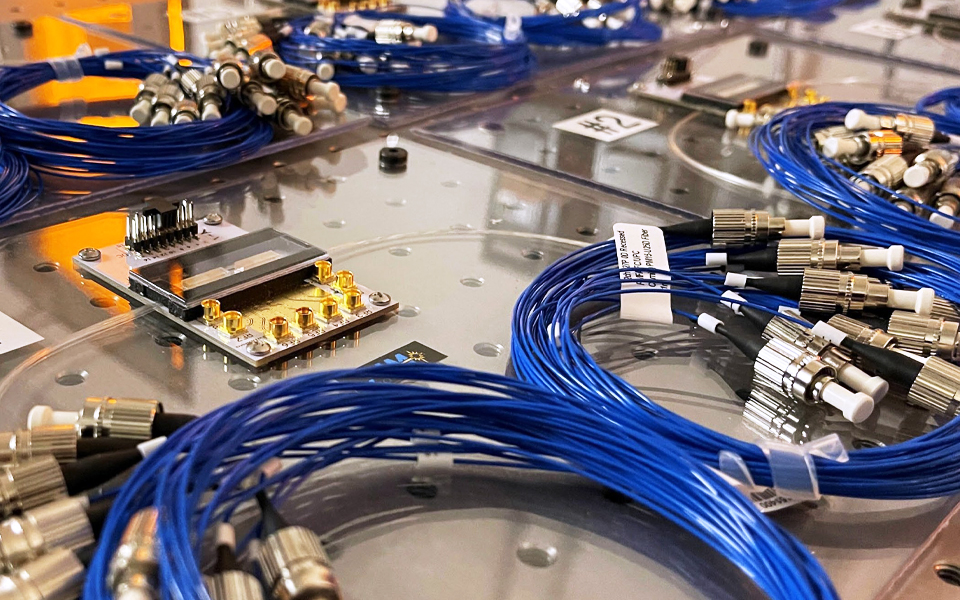

Application 1: High-Speed Optical Module Connector Wiring

In the field of optical communication, the transmission rate of optical modules has evolved from 100G to 400G and even 800G, placing higher demands on the precision and stability of internal wiring. TSP’s breakthrough wiring technology includes:

Ultra-Fine Coaxial Wire Design:

Using coaxial wires with a diameter of only 0.3mm, paired with Liquid Crystal Polymer (LCP) insulation, with an impedance control precision of ±0.5Ω, significantly better than the industry average.

Electromagnetic Interference (EMI) Optimization:

Through a multi-layer shielding design, the shielding effectiveness is improved to above 70dB, complying with international communication standards (such as IEEE 802.3), ensuring high-speed signal integrity.

Industry Value:

Test data show that optical modules using TSP wiring can reduce signal delay by 15%-20%. A leading communication equipment manufacturer has applied this technology in the mass production of its 400G optical modules, significantly improving transmission efficiency.

(Source: Internet. Deleted if infringed)

Application 2: Micro-Wiring Inside Chip Packaging

As chip manufacturing processes move into the nano-scale, the wiring density and temperature resistance inside the packaging have become key factors affecting yield rates. TSP’s wiring technology in this scenario offers the following advantages:

Extreme Wire Diameter and Temperature Resistance:

Using 0.05mm gold-plated copper wires that can withstand 300℃ high-temperature reflow soldering, breaking the traditional material limit (typically 250℃).

Enhanced Wiring Density:

Through precision laser processing, the wiring density inside chips is increased to 200 lines/mm², supporting 2.5D/3D advanced packaging requirements.

Industry Impact:

Research institutes predict that the advanced packaging market will maintain double-digit growth over the next five years. TSP’s technology has helped a semiconductor company increase its packaging yield from the industry average of 88% to 94%, while also reducing production costs by approximately 18%.

(Source: Internet. Deleted if infringed)

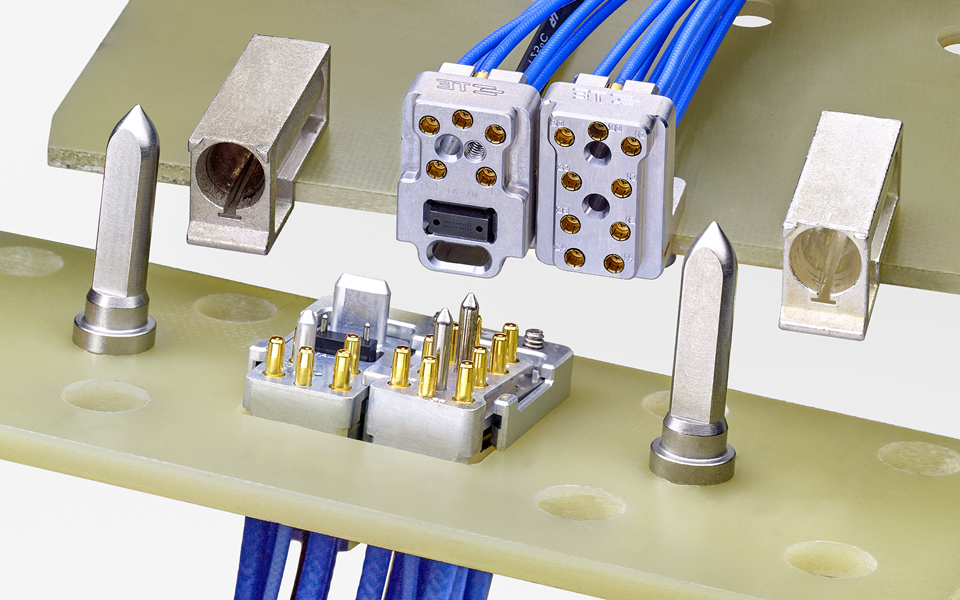

Application 3: Flexible Connections for Base Station Antenna Arrays

The large-scale deployment of 5G base station antennas imposes stringent requirements on the wiring’s weather resistance and installation efficiency. TSP’s solution includes:

Extreme Environmental Adaptability:

Using Fluorinated Ethylene Propylene (FEP) outer insulation material, with performance fluctuation of less than 3% in the temperature range from -40℃ to 125℃, suitable for long-term outdoor deployment.

Modular Quick Plug-and-Play Design:

By standardizing interfaces and pre-assembled structures, the antenna unit installation efficiency is improved by 50%, significantly shortening the base station construction cycle.

Measured Effects:

A pilot project by a telecom operator showed that the signal loss rate of base station antenna arrays using TSP wiring dropped from 0.8% to 0.1%, while operational and maintenance costs were reduced by 30%.

Conclusion: Redefining the Connection Standards for Communication Equipment

From fiber-optic transmission to chip packaging, TSP’s wiring technology is reshaping the rules of high-frequency signal transmission in communication equipment through material innovation and precision manufacturing. As 6G technology development progresses, TSP has already initiated laboratory testing for terahertz-band wiring (e.g., 0.1THz frequency validation), providing technical reserves for future communication standards.

“As communication technology advances toward millimeter waves and terahertz frequencies, TSP’s wiring innovations have become the invisible cornerstone of performance leaps in equipment.”

To read more: Automation Trends You Can’t Ignore in 2025