1. What is a Precision Mold?

Precision molds are critical tools in manufacturing that shape raw materials into high-precision, high-quality components. They meet stringent requirements for size, shape, and performance across industries such as automotive, electronics, medical, and industrial sectors.

2. Detailed Classification of Precision Molds

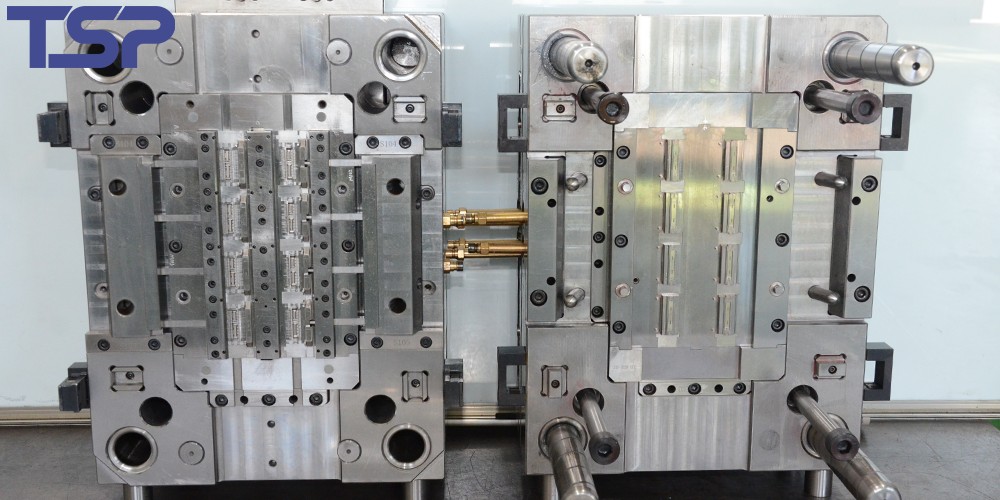

2.1 Injection-Type Molds

Structure and Process

Injection molds and die casting molds fall into this category. These molds feature cavities, cores, gating systems, cooling channels, and ejection mechanisms. Molten material is injected at high pressure into the mold cavity, then cooled and solidified. Injection molds are used for thermoplastics, while die casting molds are for metal alloys.

Materials

Thermoplastics: ABS, PP, PC, PA, etc.

Metal alloys: Aluminum, zinc, magnesium

Typical Applications

Automotive dashboards and door panels

Electronic device housings (phones, laptops)

Medical device casings

Household appliance components

Advantages

Highly automated, suitable for mass production

High precision and intricate details

Fast cooling cycles

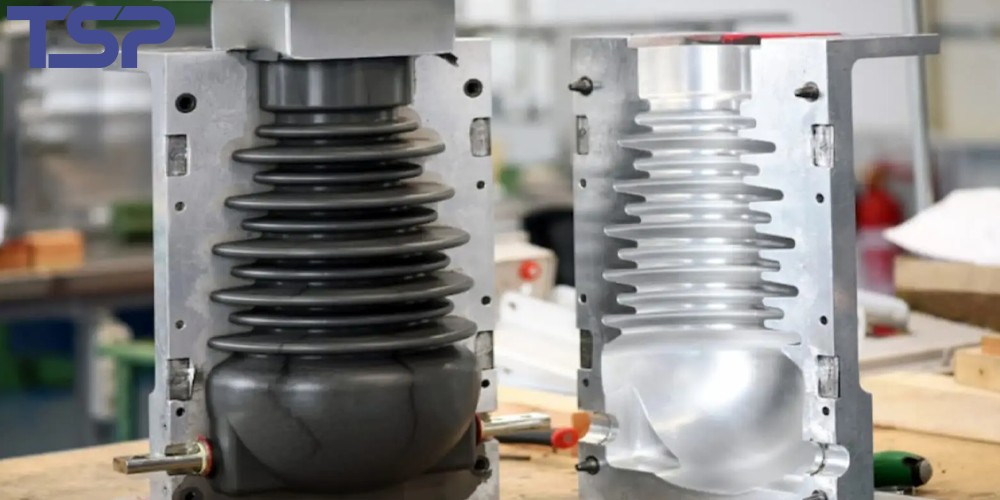

2.2 Compression-Type Molds

Structure and Process

Compression molds have simpler designs, typically upper and lower halves without gating systems. Thermosetting plastics or rubber materials are placed directly in the mold cavity, then heat and pressure are applied to cure the material. Powder metallurgy molds also belong here, compressing metal powders into parts.

Materials

Thermosetting plastics: DMC, BMC

Rubber materials: Silicone, natural, synthetic rubber

Metal powders: Iron-based, copper-based

Typical Applications

Electrical insulation housings

Automotive engine parts

Seals and vibration dampers

Mechanical gears and bearings

Advantages

Suitable for heat-resistant and high-strength parts

Lower mold manufacturing cost and easy maintenance

Can process difficult-to-melt and elastic materials

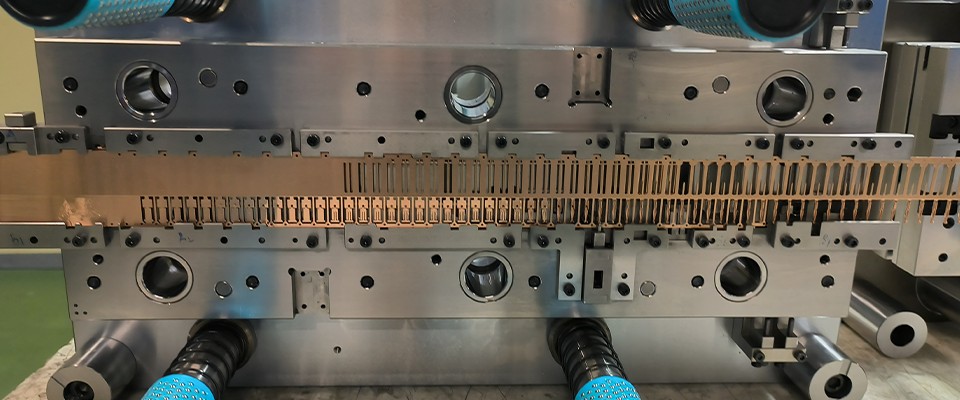

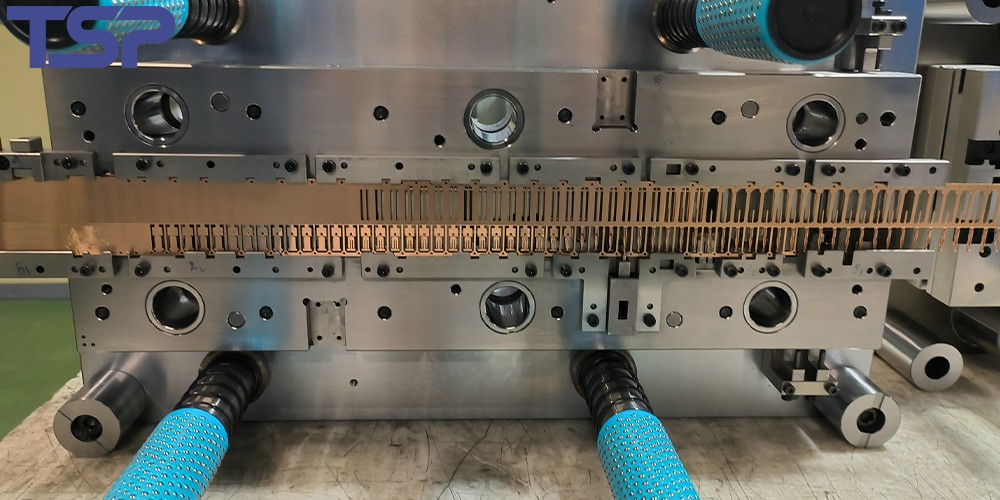

2.3. Sheet-Metal Dies

Structure and Process

These molds are used to stamp, deep draw, and bend metal sheets with presses. Components include upper die, lower die, guide posts, and ejector mechanisms, providing stable, efficient forming.

Materials

Various steel sheets (cold rolled, hot rolled, stainless steel)

Aluminum alloy sheets

Typical Applications

Automotive body panels

Battery connectors

Appliance metal housings

Industrial equipment enclosures

Advantages

High production efficiency, suitable for large volumes

Precise and repeatable dimensions

Mature, stable processes

2.4. Specialty Molds

Structure and Process

Specialty molds are custom-designed for unique materials and forming methods, including:

Wire drawing dies: For thinning metal wires via carbide openings

Optical molds: High-precision molds for optical plastic or glass parts with ultra-smooth surfaces

Glass molds: High-temperature resistant molds for glass bottles and containers

Spinning molds: For rotational forming of thin-wall metal parts

Materials

Copper, aluminum, steel wire

Optical plastics and glass

Metal sheets

Typical Applications

Wire and cable manufacturing

Optical lenses and lighting

Glass bottles and containers

Aerospace and pressure vessel parts

Advantages

Customized for special requirements

Ensures high precision and functionality

Meets high-value industry standards

3. Summary Comparison Table

| Category | Materials | Forming Process | Typical Applications | Key Advantages |

|---|---|---|---|---|

| Injection-Type Molds | Thermoplastics, metal alloys | High-pressure injection and cooling | Automotive electronics, medical, appliances | High precision, high efficiency, mass production |

| Compression-Type Molds | Thermosetting plastics, rubber, powders | Heat and pressure curing | Electrical parts, automotive, seals | Heat resistance, high strength, low cost |

| Sheet-Metal Dies | Various metal sheets | Stamping, deep drawing, bending | Auto body, battery parts, industrial equipment | High throughput, mature process |

| Specialty Molds | Wire, optical plastics, glass | Wire drawing, optical forming, spinning | Optics, cables, glass products, aerospace | Customization, high precision |

4. Conclusion

Choosing the right type of precision mold is foundational to smooth manufacturing and quality assurance. Understanding mold structures and applications enables manufacturers to optimize processes and enhance competitiveness. We offer comprehensive mold design and manufacturing services to help clients achieve high quality and efficiency.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone