Why do robotic wiring harnesses fail? How do you choose flexible, torsion-resistant cables and high-reliability connectors for industrial and collaborative robots? This guide explains everything from design and selection to installation, testing, and maintenance — with insights from a professional manufacturer.

1. What Is a Robotic Wiring Harness and Why Is It Different?

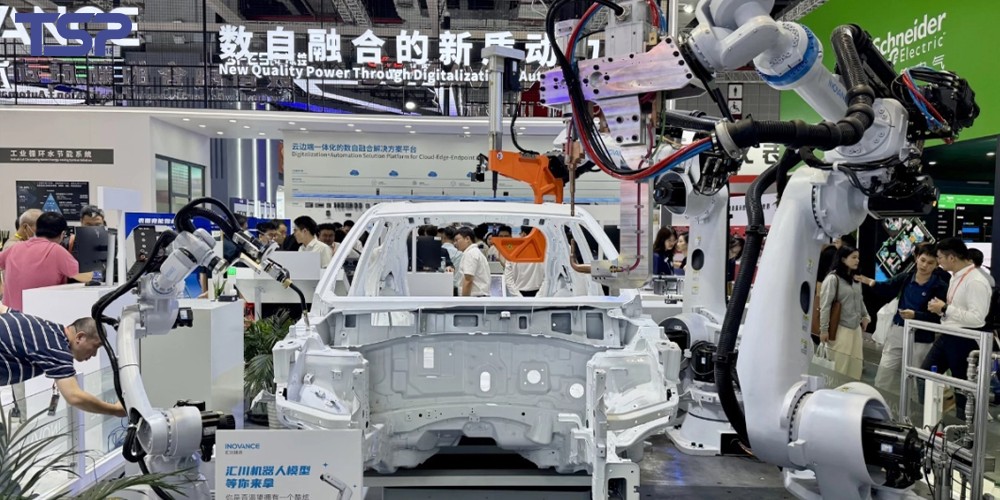

On an industrial automation line, robots operate in high-speed, long-duration, repetitive motion cycles. Compared to the harnesses used in household appliances or fixed machinery, robotic wiring harnesses must endure:

-

Continuous bending and torsion: A 6-axis arm can perform thousands of motion cycles per hour.

-

Frequent acceleration and deceleration shocks: Common in high-speed welding, sorting, and assembly.

-

Exposure to oil, chips, and chemicals: Especially in automotive and metalworking environments.

-

Electromagnetic interference (EMI): Disrupts signal stability.

If a standard harness is used, insulation cracking, conductor breakage, or signal degradation can occur quickly — leading to downtime and costly repairs.

2. Core Design Factors in Robotic Wiring Harnesses

Robotic harnesses should be designed with these key factors in mind:

2.1 Flex Life

-

High-quality robotic cables can withstand 5–10 million bending cycles in lab tests.

-

Minimum bend radius is typically 7–10× the cable’s outer diameter to avoid conductor fatigue.

-

Example: igus data shows polyurethane (PU) sheathing offers superior wear and oil resistance compared to PVC, making it ideal for high-flex applications.

2.2 Jacket & Insulation Materials

-

PU (Polyurethane): Wear-, oil-, and low-temperature-resistant; highly flexible.

-

TPE (Thermoplastic Elastomer): Excellent chemical resistance and flexibility.

-

PVC (Polyvinyl Chloride): Low cost, but lower flex and abrasion performance.

2.3 Shielding & Signal Integrity

-

Braided copper shields + foil shields protect against both high- and low-frequency interference.

-

When power and signal lines share a harness, proper layering or separate sheaths reduce crosstalk.

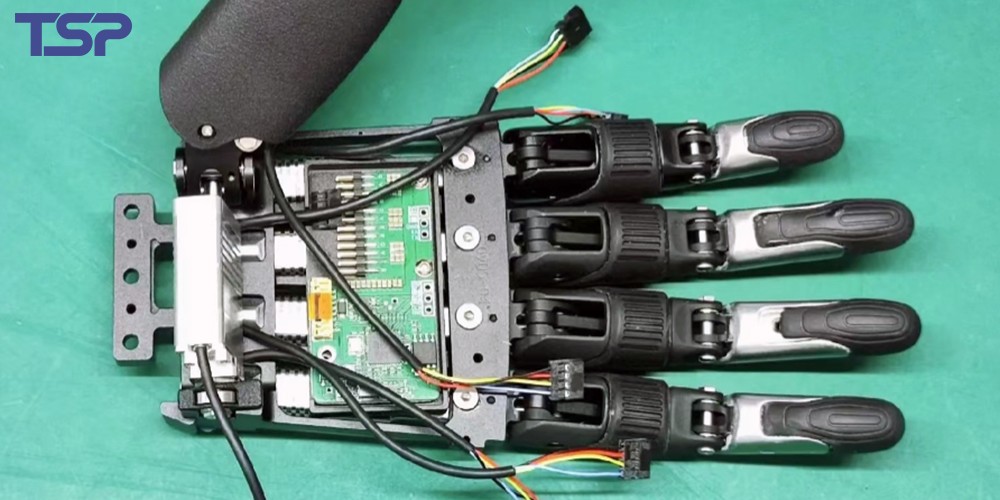

2.4 Connector Protection

-

Common types: M12 / M8 industrial connectors, Harting Han, custom quick-disconnects.

-

Aim for IP67 or IP68 protection in environments with coolant, oil mist, or dust.

-

Include strain relief to prevent repeated stress at the connector interface.

3. Mechanical Cable Management

Many harness failures are caused not by cable quality, but by improper routing and fixation.

-

Cable carriers / drag chains: Reduce friction and wear against machine parts.

-

Correct slack allowance: Enough for movement but no loose loops.

-

Strategic fixation points: Avoid fixing at maximum bend points.

-

Torsion management: Use torsion-rated cables and install according to the manufacturer’s torsion direction guidelines.

4. Testing & Quality Control

A robotic wiring harness should undergo rigorous testing to ensure reliability under stress:

-

Bending fatigue testing (simulating joint motion)

-

Vibration testing (simulating high-speed impact)

-

Insulation resistance and dielectric strength testing

-

Contact resistance measurement

-

Ingress protection (IP) testing

5. Common Failures and How to Prevent Them

The most frequent issues are:

-

Conductor breakage: Often from tight bend radii or over-extension.

-

Jacket wear: From rubbing against sharp edges.

-

Connector faults: Caused by vibration, corrosion, or strain.

-

Signal interference: From damaged shielding or poor grounding.

Prevention tips:

-

Regularly inspect jackets, shields, and connectors.

-

Replace high-wear harnesses on a preventive schedule.

-

Follow OEM routing specifications during repairs or modifications.

6. Purchasing & Selection Checklist

When sourcing a harness for industrial or collaborative robots, consider:

-

Conductor size (current and voltage requirements)

-

Flex life rating (≥5 million cycles)

-

Jacket & insulation materials

-

Shielding method

-

Connector type & IP rating

-

Environmental resistance (oil, chemicals, temperature range)

-

Warranty & recommended replacement interval

7. Our Solutions — Precision Matters

As a precision mold and precision wiring harness manufacturer, we deliver harness solutions engineered for robotic applications:

-

High-flex, long-life cables: Lab-tested to millions of cycles for multi-axis arms.

-

Custom-built designs: Tailored to robot models, lengths, connectors, and routing paths.

-

Precision mold expertise: Ensures connector housings meet exact tolerances for secure fit.

-

Full supply chain control: From conductor to molding, guaranteeing consistent quality.

Our harnesses are trusted in automotive, electronics, and medical manufacturing — helping customers cut maintenance costs and keep production running at peak efficiency.

8. Conclusion

The reliability of a robotic wiring harness directly impacts uptime and operating cost.

By selecting the right materials, structure, mechanical protection, and maintenance plan, you can dramatically extend service life and avoid costly breakdowns.

If you need custom high-reliability harnesses for industrial or collaborative robots, our team offers engineering-driven design, precision manufacturing, and end-to-end quality control to meet your application demands.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone