TSP has over 26 years of expertise in providing large-scale connectivity and wiring harness solutions.

With a comprehensive range of capabilities, TSP supports your project through every phase of development.

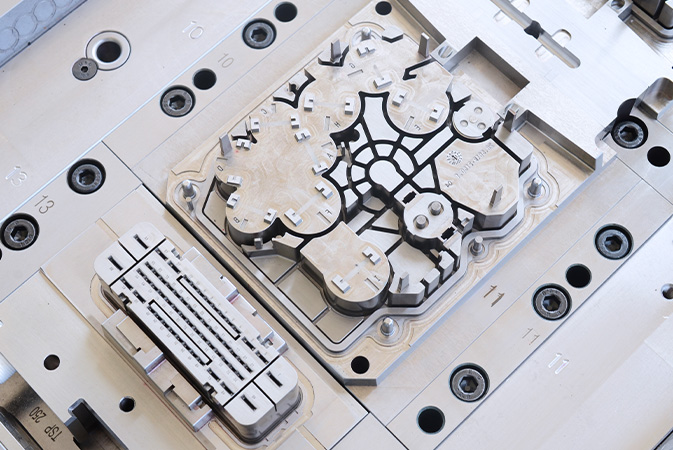

We utilize advanced CNC technology and materials to produce high-precision molds, ensuring that every product meets strict quality standards.

| Mold | Die | |

|---|---|---|

| Technician | 80 | 35 |

| Designer | 40 | 15 |

| Assy & Debug | 40 | 20 |

| Output/year | 550 | 180 |

| Software | Creo 4.0, NX 8.5-12.0, Moldflow 2021 | AutoCAD2016, Solidworks 2019, LogoPress |

| SH | Anhui | SLP | Total | Brand | Accuracy | |

|---|---|---|---|---|---|---|

| Sink EDM | 20 | 22 | 2 | 44 | Agie Charmilles / Makino | 0.002 mm |

| Grinder | 20 | 32 | 2 | 54 | Okamoto | 0.001 mm |

| High-speed CNC | 10 | 9 | 1 | 20 | Moriseiki / Makino | 0.002 mm |

| Wire EDM | 9 | 5 | 1 | 15 | Agie / Charmilles / Sodick | 0.002 mm |

| Profile Grinder | NA | 2 | NA | 2 | WAIDA | 0.001 mm |

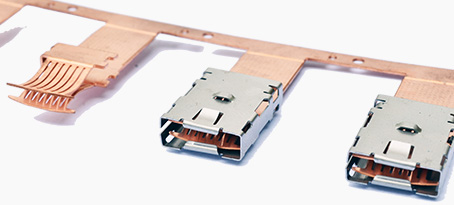

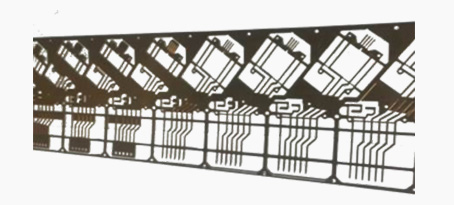

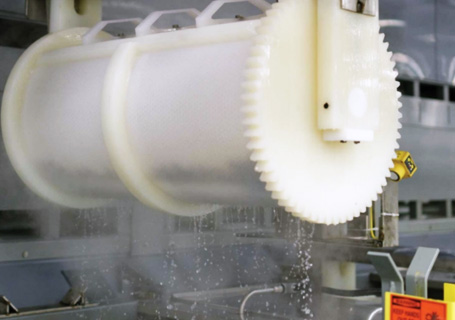

Our stamping process efficiently processes various metal materials, suitable for large-scale production, ensuring consistency and reliability in every product.

| Machine | Speed | Strip Thickness | Pitch | Die Length |

|---|---|---|---|---|

| 40T – 200T. Total 20 units. Yamada, Kyori, Micron, CF | 40SPM – 1000SPM | 0.05mm – 2.5mm | 0.4mm – 100mm | 150mm - 2000mm |

+Au, +Ag, +Sn, +Ni, +Pa, +Cu, etc.

Resin:

PA, PBT, POM, ABS, PPO, PPA, PAA, PES, PSU, PEI, LCP, PPS, PEEK, PC, PCT, PET, TPU

| High stability precision injection molding | ||

|---|---|---|

| Machine | 30T – 320T. Total 120 units. Arburg, Fanuc, Sumitomo, ENGEL, Nissei, Multiplas | |

| Screw Size | 12 – 70 mm | |

| Max. Speed | 600mm/s | |

| Parts Weight | 0.06g – 700g | |

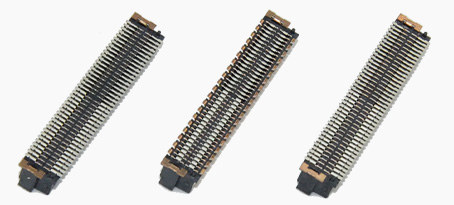

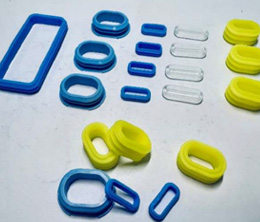

Our insert molding technique combines multiple materials, ensuring component strength and durability, ideal for producing intricate products.

| Vertical Machine | Screw Size | Shot Weight | Type |

|---|---|---|---|

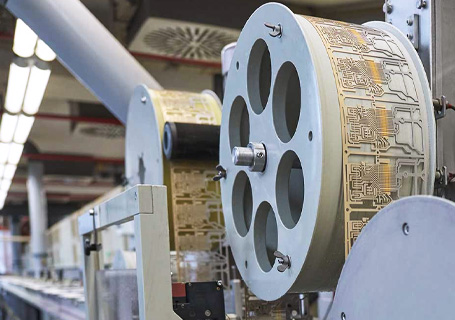

| 40T – 160T. total 40 units | 14 – 42 mm | 1g – 150g | Slide table, Rotation table, Single motion, reel to reel motion |

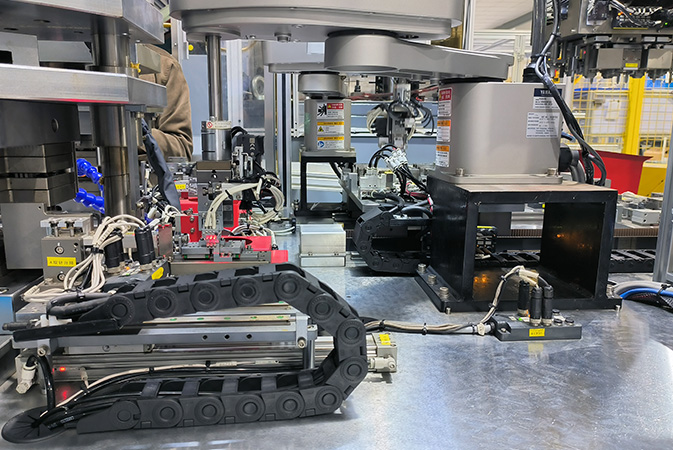

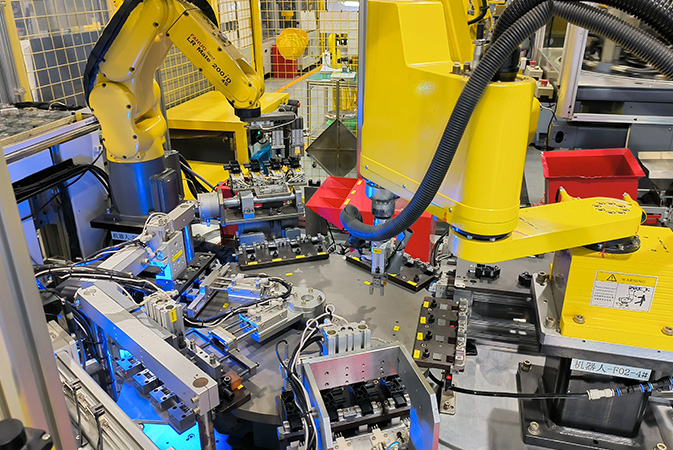

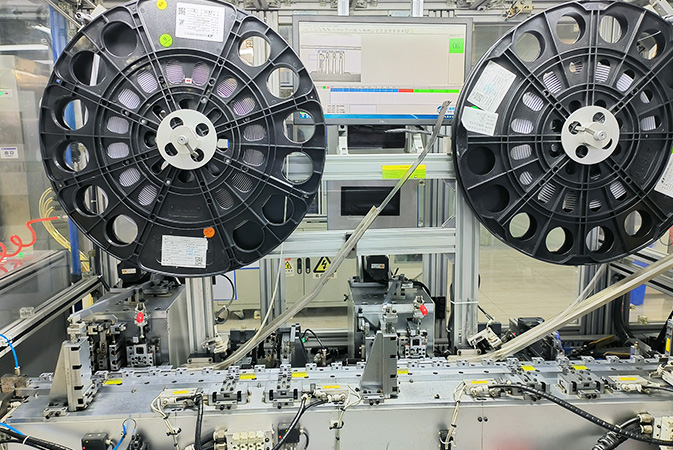

Our efficient automated production lines enable rapid assembly of complex components, enhancing production efficiency and product quality.

| Assembly Line | Output/Month | Assembly Process |

|---|---|---|

| 30 (Fully/Semi Automatic) | 80 Mio Pcs | Stitching, Bending, Cable, Welding, Screwing |

Fully Automatic Thread-Cutting Machine

• KOMAX: 3 units

• Schleuniger: 5 units

| Engineer | Output/Month | Production Line |

|---|---|---|

| 24 | 2.4 Mio Pcs | 80 |

At TSP, we believe in a smooth, collaborative approach that ensures the success of every project. Our process is designed to provide clarity and efficiency, from concept to completion.

We work with you to understand your specific requirements and project goals.

Our team develops optimized designs that ensure manufacturability at scale.

We produce prototypes for validation, ensuring your specifications are met before full-scale production.

Upon approval, we move into large-scale manufacturing with tight quality control.

We ensure timely delivery and offer ongoing support as your project evolves.