If you’re an OEM or system integrator, you’ve probably come across both cable assemblies and wire harnesses when planning your product’s electrical system.

These two terms are often used interchangeably — but they are not the same. Choosing the wrong one can lead to unnecessary costs, performance issues, or reliability problems down the road.

Let’s break down the key differences between a wire harness and a cable assembly, and how to choose the best fit for your application.

What Is a Wire Harness?

A wire harness is a collection of multiple insulated wires bundled together with ties, sleeves, or tubing. It helps organize and route electrical wiring inside a device or system.

Key Features:

Typically used inside equipment where environmental protection is not a major concern.

Each wire usually has its own insulation.

Bundled together with tape, ties, or conduits.

Often built manually or semi-automatically on assembly boards.

Advantages:

Cost-effective for large, complex internal wiring systems.

Easy to modify and repair.

Ideal for controlled environments (e.g., inside enclosures).

Common Applications:

Automotive dashboards, industrial control panels, robotics wiring, home appliances.

What Is a Cable Assembly?

A cable assembly is a group of wires or cables enclosed within a single, protective outer jacket — often terminated with connectors, overmolding, or shielding for extra durability.

Key Features:

Designed for point-to-point connections.

Offers protection against moisture, heat, vibration, and abrasion.

Includes connectors, strain reliefs, and sometimes overmolded housings.

Built with high-precision automated processes.

Advantages:

Excellent durability and reliability.

Withstands harsh environments and outdoor use.

Faster to install — plug-and-play ready.

Common Applications:

Electric vehicles, telecommunications equipment, industrial automation, medical devices.

Cable Assembly vs. Wire Harness: Quick Comparison

| Feature | Wire Harness | Cable Assembly |

|---|---|---|

| Structure | Multiple individual wires bundled together | Wires enclosed in a single protective jacket |

| Environment | Indoor, protected | Outdoor or harsh conditions |

| Durability | Basic protection | High resistance to heat, vibration, moisture |

| Cost | Lower upfront cost | Higher cost, longer lifespan |

| Flexibility | Easy to modify and repair | Sealed, harder to modify |

| Typical Use | Internal wiring systems | External or inter-device connections |

How to Choose the Right One

When deciding between a cable assembly and a wire harness, consider the following:

Environment

Is your product exposed to dust, vibration, heat, or moisture?

→ Choose a cable assembly.Is the wiring protected inside an enclosure?

→ A wire harness may be sufficient.

System Design

Many branches or split connections → Wire harness.

Simple point-to-point connection → Cable assembly.

Reliability & Maintenance

For mission-critical systems (EV, robotics, medical) → Cable assembly.

For frequently serviced equipment → Wire harness.

Cost Efficiency

Harnesses cost less upfront, but assemblies often lower total ownership cost (fewer failures, faster installation).

Why Choose TSP

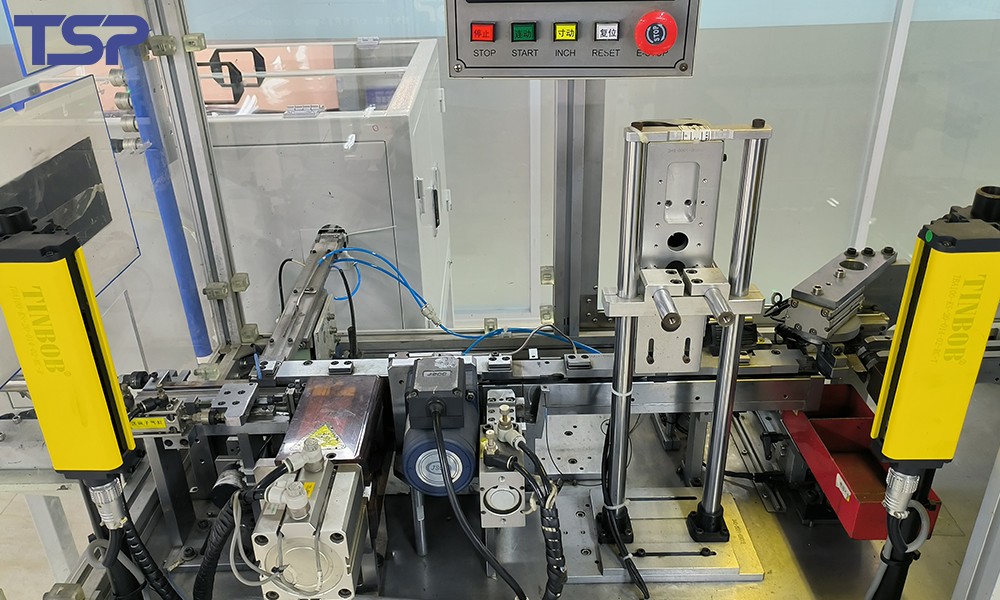

With over 26 years of manufacturing experience, TSP delivers complete interconnect solutions — from design and tooling to mass production.

✅ Full In-House Capability

Molding, stamping, insert molding, liquid silicone injection, automatic wire processing, and assembly — all under one roof.

✅ Global Manufacturing Network

Facilities in China (Shanghai, Anhui), and expansion into Mexico and Morocco to support global OEMs.

✅ Industry Expertise

Automotive • New Energy • Medical • Telecommunications • Industrial Automation • Smart Devices

✅ Customized Solutions

We design and produce both wire harnesses and cable assemblies tailored to your exact specifications and environment.

✅ High-Reliability Standards

Compliant with UL, RoHS, and automotive-grade requirements. Designed to perform in demanding conditions.

Frequently Asked Questions

Q1: How do I know which one I need?

→ If your system is exposed to harsh conditions, choose a cable assembly. For internal wiring with multiple branches, go with a wire harness.

Q2: Can TSP make both types?

→ Yes. TSP provides complete design and production for both wire harnesses and cable assemblies.

Q3: Can I order prototypes first?

→ Absolutely. We offer rapid prototyping and testing before full-scale production.

Q4: Are cable assemblies more expensive?

→ Typically yes, but they often reduce downtime and maintenance, lowering your total cost in the long run.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone