A Battery Management System (BMS) is the core intelligence of every modern lithium battery platform — from residential ESS units and large-scale energy storage stations to electric vehicles, AGVs and industrial power systems. As battery technology evolves, the wiring harness behind the BMS becomes increasingly critical. High-precision signal transmission, stable communication and reliable current pathways all depend on a well-designed BMS wiring harness.

This article analyzes the key elements of BMS wiring harness structure design, signal transmission requirements, insulation and safety considerations.

1. Why the BMS Wiring Harness Determines System Stability

The BMS wiring harness is far more than a cable bundle. It is the nerve network of any lithium battery system. Its core responsibilities include:

Collecting cell voltage signals

Transmitting temperature data

Balancing and equalization control

Carrying communication signals & CAN/RS485/SMBus

Power transmission and high-current paths

Safety feedback and fault detection

If any signal is lost, delayed or interfered with, the battery pack may experience:

✔️ Unstable SOC/SOH calculations

✔️ Overcharge / over-discharge risks

✔️ Thermal runaway risks

✔️ Degraded cycle life

✔️ System shutdown or communication interruptions

Therefore, a reliable BMS harness is essential for EV-grade reliability and ESS long-term stability.

2. Structure Design Essentials of BMS Wiring Harnesses

A high-quality BMS wiring harness must be engineered for precision and endurance. Critical design points include:

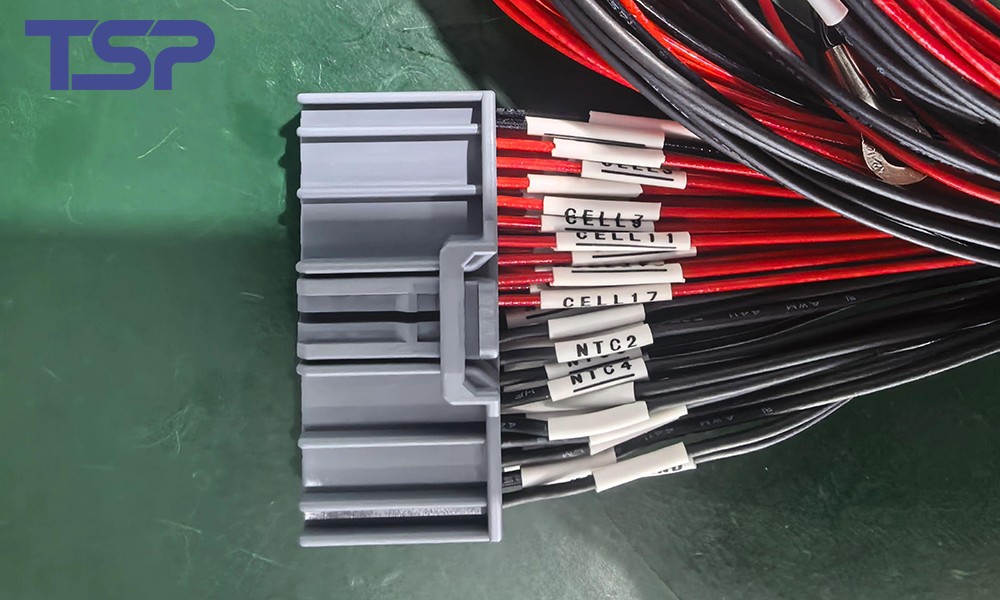

2.1 High-Density Connector Selection

The harness typically connects:

Cell voltage collection boards (VCU/DBC)

Temperature sensors

Pack-level CAN/RS485 interfaces

Current sensors / shunt / Hall sensors

2.2 Balanced Voltage Loop Architecture

For LFP (LiFePO4) and NCM systems, wiring topology must ensure:

Equal wire length for each cell sampling line

Minimized differential noise

Secure insulation spacing

Safe routing away from high-current sections

2.3 Temperature Sensing Network

A stable thermal feedback system includes:

NTC/PTC sensors

Shielded twisted pairs

Heat-resistant and flame-retardant materials

Spot welding or all-in-one integrated harness design

This ensures accurate temperature monitoring—critical for safeguarding large ESS installations.

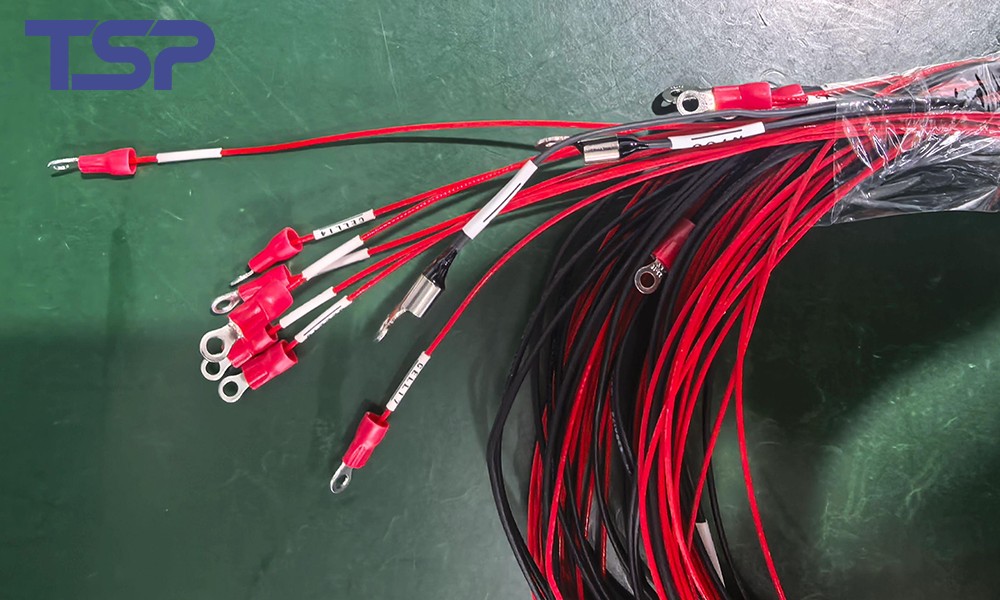

2.4 HV and LV Separation

To avoid EMI interference:

High-voltage cables and low-voltage signal cables must be separated

ISO 21498 and EV standard routing principles are followed

Shielding may be added for CAN/RS485 communication lines

3. Signal Transmission Requirements in BMS Harnesses

Signal quality is the determining factor of BMS performance.

3.1 Voltage Sampling Accuracy

Sampling wires must ensure:

Low resistance

Minimal signal loss

Consistent voltage drop

Strong anti-interference shielding

3.2 Temperature Signal Stability

Each battery module relies on accurate NTC readings:

Incorrect readings cause false alarms

Over-sensitivity triggers unnecessary shutdowns

Low sensitivity creates thermal risk

3.3 Communication Reliability

BMS commonly uses:

CAN 2.0B

CAN FD

RS485

SMBus / I2C

UART

To guarantee reliable communication:

Shielded twisted-pair cable

Controlled impedance

EMI/EMC design principles

Robust connector locking systems

This is essential for EV, heavy equipment, and large industrial ESS.

4. Material and Manufacturing Requirements

A reliable BMS wiring harness must meet demanding mechanical and environmental conditions.

4.1 Cable Materials

XLPE insulation

TPU for abrasion resistance

High-flex silicone for EV packs

UL-certified materials for export markets

4.2 Mechanical Strength

BMS harnesses often endure:

Vibration

Temperature cycling

Chemical exposure

Installation bending

4.3 Safety Compliance

Depending on the application:

UL94-V0

ISO 19642 (Road Vehicle Wiring)

IEC 62619 (ESS Batteries)

GB/T 34013

All TSP BMS harnesses can be produced with full certification support.

5. Why Leading Battery Manufacturers Choose TSP

TSP is a global precision wiring harness and connector solution provider with manufacturing in Mexico and Morocco, serving EV, ESS energy storage, medical, and industrial customers.

✔ 6+ years OEM & ODM experience

✔ Complete in-house molding and connector development

✔ Full BMS wire harness engineering capability

✔ Automated production for consistent quality

✔ Flexible customization from prototype to mass production

Our partners include world-class companies such as:

TE Connectivity, Sensata, Phoenix Contact, Molex, etc.

What TSP delivers:

Customized BMS wiring harness solutions

Balanced voltage sampling harness

CAN/RS485 communication harness

Pack/module temperature sensor harness

Cell monitoring board harness (CMU/VCU)

High-voltage harness with IP67/IP68 protection

We support EV battery packs, LFP energy storage cabinets, telecom backup, residential ESS, AGV/AMR batteries, UPS systems, and more.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone