In today’s fast-evolving mobility sector, OEMs and Tier-1 suppliers face ever-greater demands for reliability, durability and performance in their wiring systems. Two cornerstones of success are robust automotive wire harness design and appropriate ingress protection (IP) ratings. Get them wrong, and you risk equipment failure, high warranty costs or even safety issues. As a seasoned connectivity partner with over 26 years of expertise, TSP helps you navigate these challenges—and deliver harnesses that meet stringent automotive requirements.

Why automotive wire harness design matters

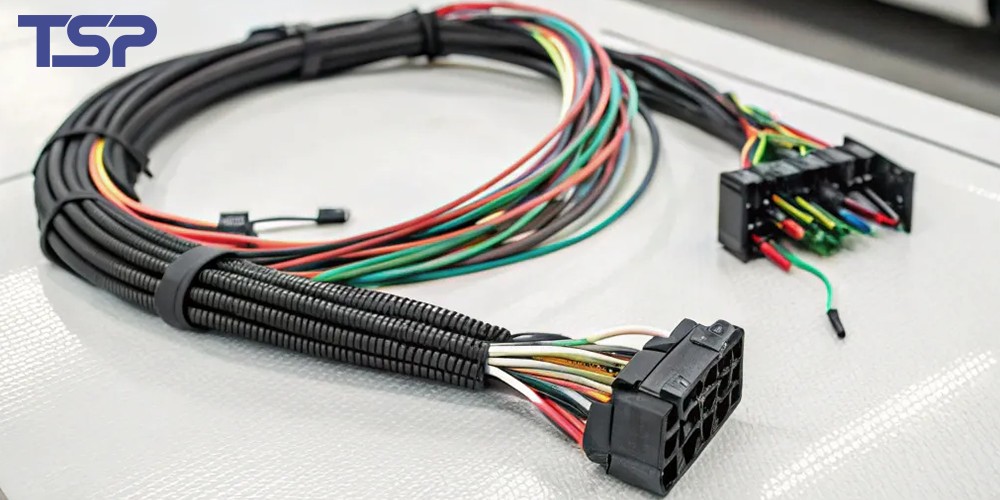

A proper wire harness isn’t just “lots of wires bundled”—it’s a precision-engineered interconnect system that must handle vibration, thermal cycles, humidity, electromagnetic interference (EMI) and mechanical strain.

In automotive and e-mobility applications, harnesses link critical systems: battery management, ECU, sensors, actuators, lighting. Faulty harness design leads to downtime or safety risk.

Core considerations in harness design for automotive

– Layout & routing

Design must account for space constraints, branch points, connectors, shielded segments and serviceability.

– Material & conductor selection

Choose correct conductor size (AWG), insulation, shielding to meet current, signal integrity and environment.

– Termination & connectorization

Reliable crimps, insert-molding, overmolding – robust beyond just standard assembly.

– Vibration, thermal, environmental stresses

Harnesses must survive harsh conditions: high/low temps, moisture, salts, chemicals, rough terrain.

– Standard & compliance

Automotive ecosystems often call out standards like IPC/WHMA-A-620, OEM specs, ISO 26262 (functional safety) and more.

Understanding IP Ratings & why they’re critical

“IP” stands for Ingress Protection. It’s a standard that defines how well an enclosure (or connector/harness) resists intrusion by solids (first digit) and liquids (second digit).

Example: IP67 means “dust tight” + “immersion up to 1 m”.

In automotive use-cases (engine bay, battery pack, electronic modules, exterior cameras), IP ratings ensure wiring and connectors remain sealed under rain, salt spray, wash-down, exterior exposure.

Choosing the wrong IP rating can lead to moisture ingress, corrosion, shorts, sensor failures.

For OEMs looking to integrate into high-reliability applications (EVs, ADAS, off-road, industrial vehicles), partnering with a supplier who understands IP rating integration into the harness/connector assembly is key.

Designing a wire harness with IP-rated connectors and protection

Start with environment mapping: Define where harness runs (interior, engine bay, underbody, external). Assign expected temperature, moisture, mechanical exposure.

Define target IP rating: Depending on exposure, choose e.g., IP54 (splash-proof), IP67 (immersion), IP69K (high pressure/high temp wash-down).

Select appropriate connector/housing system: Must certify to the desired IP rating when mated and when unmated if relevant.

Harness routing & protection: Use overmolding, potting, seal boots, braided shields, conduits to maintain sealing.

Test and validate: Environmental testing (thermal cycling, salt spray, vibration, mating/unmating cycles) to confirm harness meets design target.

Production readiness & quality assurance: Ensure supplier has capabilities from mold design, stamping, insert molding, harness assembly and global manufacturing footprint for consistency and scale.

Why choose TSP for your automotive harness and IP-rated connectivity needs

Global manufacturing footprint (Shanghai, Anhui, Mexico, Morocco) ensures supply chain flexibility and localized support.

Full-chain engineering prowess: tooling → mold → stamping → insert molding → full harness assembly, meaning faster DFM/DFT and lower risk.

Deep experience in mobility applications: connectors and harnesses designed for battery systems, steering control, sunroof wiring, emission systems etc.

Designed for harsh environments: TSP’s solutions are built to meet demanding IP ratings, vibration specs and automotive lifecycle requirements.

OEM-oriented collaboration: We work with you from concept through to mass production, supporting custom IP-rated harness builds that align with your system architecture.

Next-steps for OEMs & design teams

Map your system wiring requirements and environment exposure.

Determine target IP rating for each wiring sub-system.

Engage early with a supplier who can collaborate on DFM, prototyping, validation and mass production.

Request a sample/quote: Let TSP evaluate your harness layout, connector needs, environmental specs.

Plan for testing & validation early to avoid late-stage surprises which cost time and money.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone