With the explosion of electric vehicles (EVs) and autonomous driving technologies, the North American automotive industry is facing unprecedented transformation pressures. According to Statista, North America’s automotive production accounted for 18% of global output in 2023, but the demand for supply chain localization grew by over 35% year-on-year. The shortage of high-precision molds, cross-border quality consistency, and compressed delivery cycles have become core pain points for automotive manufacturers. In response to these challenges, automakers are continually seeking high-efficiency, low-cost, and flexible solutions.

TSP’s Mexico facility, with its automation technology and precision mold manufacturing capabilities, is becoming a key player in the North American automotive supply chain. TSP provides high-precision connectors, sensors, wire harnesses, and other essential components, while also leveraging automated assembly and production lines to boost efficiency and supply chain responsiveness.

Strategic Location Value of TSP's Mexico Facility

Geographic Advantage

TSP’s Mexico facility is located in San Luis Potosí’s Fracc. Interpuerto WTC, at Priv. Principal #170, CP 78426, about 400 kilometers from the Texas border, allowing quick access to 80% of the automotive industry clusters in North America (data source: Mexico Ministry of Economy, 2023 Manufacturing Investment Report).

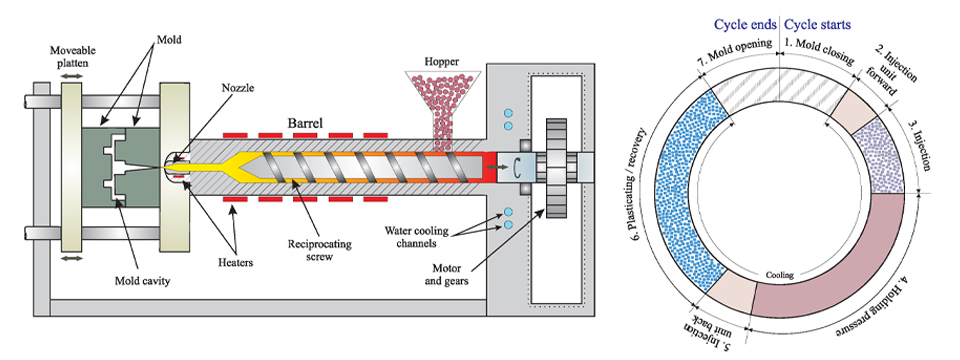

Automation Production Line Configuration

Precision Molding Workshop

The facility uses AI vision inspection systems and laser measurement technology, achieving mold processing accuracy of ±0.002mm (industry average is ±0.01mm).

Automated Assembly Line

Collaborative robots (cobots) are employed for wire harness assembly, reducing manual intervention by 50%. This has reduced the order delivery cycle for a North American automaker from 6 weeks to 3 weeks.

Data Support

According to data from the Mexican National Institute of Statistics and Geography, Mexico’s automotive parts exports to the U.S. surpassed $90 billion in 2022, highlighting Mexico’s critical role in North America’s automotive supply chain.

TSP Mexico Manufacturing Facility

How Automation Technology Solves Core Supply Chain Pain Points

Module 1: Precision and Consistency Assurance

Mold production adopts a CAD/CAM end-to-end digital design, with design parameters synchronized in real-time between the Mexico and Shanghai factories to ensure global quality control consistency. TSP’s Mexico facility achieves a product defect rate of just 0.12%, far below the industry average of 0.8% (based on IATF 16949 certification standards).

Module 2: Flexible Production Capacity

In 2023, a North American EV manufacturer saw a 200% surge in orders due to policy subsidies. TSP’s automated scheduling system enabled production capacity expansion within 72 hours. By continuously monitoring production progress and intelligently allocating resources, TSP was able to quickly scale up its production to meet sudden order demands. Moreover, TSP’s Mexico facility has a capacity utilization rate of 92%, significantly higher than the industry average of 75%-80%.

Module 3: Localized Service Response

TSP’s technical engineers are stationed at customer factories, ensuring that any issues are resolved within 8 hours, while traditional multinational companies typically require 48 hours for response. Additionally, TSP is directly connected to warehouses in Texas, with land transportation times under 36 hours, covering 90% of North America.

Automation Technology

Future Outlook: Automation Technology Iteration

TSP plans to implement digital twin technology in 2025 to enable predictive maintenance for the entire lifecycle of its molds. This technology will allow TSP to monitor the status of molds in real time, predict potential failures, and take proactive measures before failures occur, greatly extending the lifespan and stability of production equipment.

According to McKinsey, by 2030, the automation penetration rate in global automotive supply chains is expected to exceed 60%. TSP’s Mexico facility, with its deep expertise in automation, will play an increasingly pivotal role in this trend, becoming a key hub for smart manufacturing in North America.

Digital Twin Mold Interaction Diagram

(Source: Internet. Deleted if infringed)

Conclusion: Strengthening Trust in the North American Market

With its “automation + precision molding” dual-engine advantage, TSP’s Mexico facility has successfully met the North American automotive industry’s demands for high-quality, fast delivery, and precise manufacturing. Through advanced automated production technologies, TSP has optimized production processes, improved efficiency, and greatly enhanced supply chain flexibility and responsiveness. As a result, TSP has become the invisible champion for Tier 1 suppliers in North America, with its influence in the region expected to continue to grow in the future.

To read more: Automation Trends You Can’t Ignore in 2025