Custom precision injection molding is one of the most reliable manufacturing processes for producing complex, high-quality plastic components at scale. From medical devices and automotive parts to consumer electronics, the demand for precise, consistent, and cost-effective plastic parts has never been higher.

In this article, we’ll explore the key advantages of custom precision injection mold, compare it to standard molding approaches, and explain why it matters for industries that require uncompromising accuracy and reliability.

1. High Precision and Tight Tolerances

One of the biggest advantages of custom precision injection mold is the ability to produce parts with very tight tolerances. Precision molds can consistently achieve accuracies in the range of ±0.001 inches or even finer, which is essential for industries such as:

Medical devices – ensuring patient safety and regulatory compliance.

Automotive connectors – requiring exact fit and durability under stress.

Electronics housings – where precision affects performance and assembly.

This level of accuracy is not possible with many other manufacturing methods like 3D printing or standard machining when it comes to high-volume production.

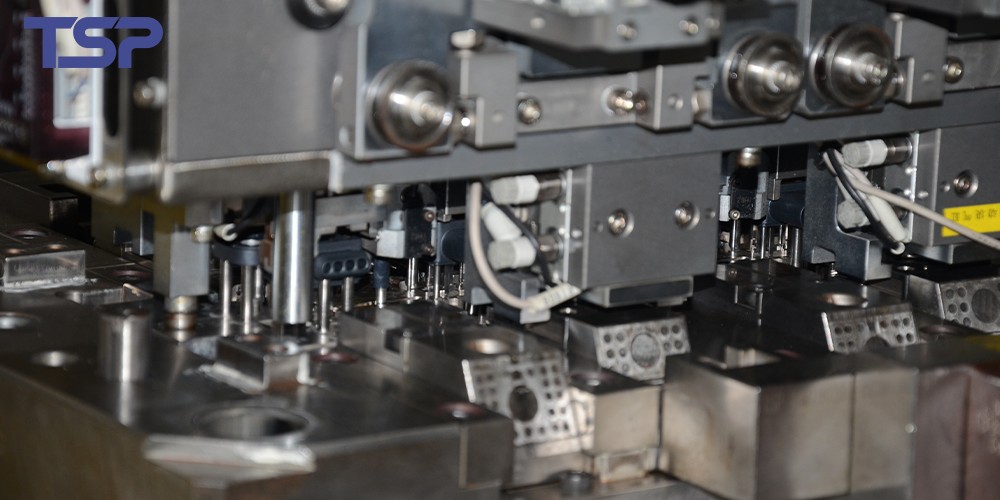

2. Superior Consistency and Repeatability

Once the mold is built, every injection cycle can produce identical components with virtually no variation. This repeatability guarantees:

Reduced defect rates.

Faster assembly processes.

Lower quality-control costs.

For industries where safety and performance cannot be compromised, repeatability is one of the most valuable benefits of precision injection molding.

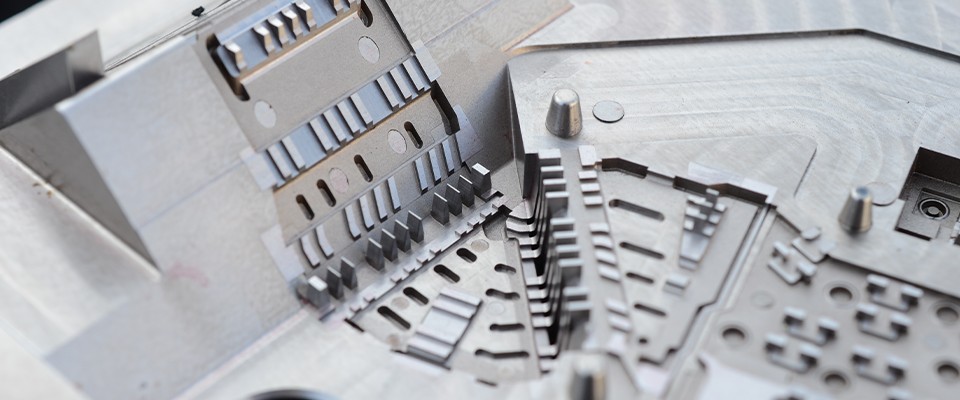

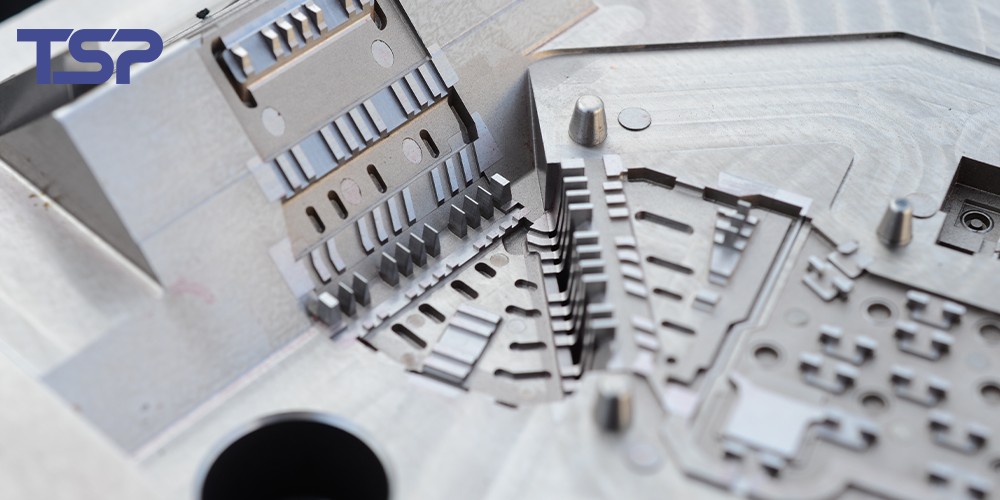

3. Complex Geometries and Design Flexibility

Custom precision molds allow engineers to design parts that would be extremely difficult—or impossible—to achieve with other methods. Advantages include:

Thin walls and micro-features.

Intricate geometries with undercuts and fine details.

Integration of branding, textures, or part numbers directly into the mold.

This design flexibility not only saves time and cost on secondary finishing, but also creates opportunities for lighter, more efficient product designs.

4. Wide Range of Materials

Another key advantage of custom precision injection mold is the diverse material selection. Manufacturers can choose from thousands of thermoplastics, resins, and additives to meet specific needs such as:

Heat resistance.

Electrical insulation.

Chemical resistance.

Mechanical strength and durability.

Advanced options like overmolding and insert molding also allow combining multiple materials in a single part, adding both functionality and strength.

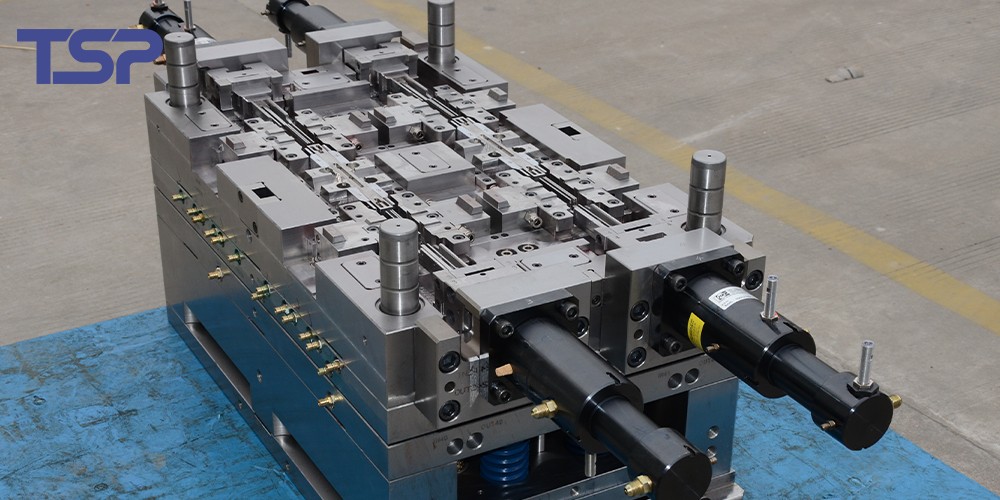

5. Cost-Effectiveness in High-Volume Production

While the initial mold investment can be significant, the per-part cost decreases dramatically as volume increases. This makes injection molding the most cost-efficient solution for mass production. Benefits include:

Low unit price for thousands or millions of parts.

Faster return on investment for large projects.

Long mold life with proper maintenance.

6. Reduced Waste and Sustainable Manufacturing

Precision molding uses material very efficiently. With optimized mold design and automated processes, waste is minimized compared to traditional machining. Additionally:

Excess material from runners or gates can often be recycled.

Energy-efficient molding machines reduce carbon footprint.

Use of bio-resins or recyclable plastics supports sustainability initiatives.

7. Faster Time to Market

Modern precision mold design, aided by CAD/CAM and rapid prototyping, reduces development time. This enables manufacturers to:

Shorten product launch cycles.

Respond quickly to market changes.

Gain competitive advantages with early market entry.

8. Durability and Reliability of Molded Parts

Products made with custom precision injection molds exhibit strong mechanical performance and reliability. This is particularly crucial for:

Automotive components exposed to vibration and heat.

Medical devices requiring long-term biocompatibility.

Industrial connectors and housings that must withstand harsh environments.

9. Scalability and Global Supply Chain Compatibility

Precision injection molding is highly scalable. Whether you need 10,000 or 10 million parts, the process adapts seamlessly. Moreover, standardized materials and global expertise ensure that components can be produced consistently across multiple facilities worldwide.

10. Limitations and How to Overcome Them

While there are many advantages, it’s worth noting:

High upfront tooling cost – mitigated by high-volume production.

Design changes are difficult after mold creation – solved by thorough prototyping and simulations.

Lead time for mold manufacturing – reduced with advanced rapid tooling.

By planning ahead and working with experienced mold partners, these challenges can be minimized.

FAQs About Custom Precision Injection Molding

Q1: What industries benefit most from custom precision injection molds?

A: Automotive, medical, consumer electronics, aerospace, and industrial equipment manufacturers.

Q2: How long does a precision mold last?

A: Depending on materials and maintenance, molds can produce hundreds of thousands to millions of parts.

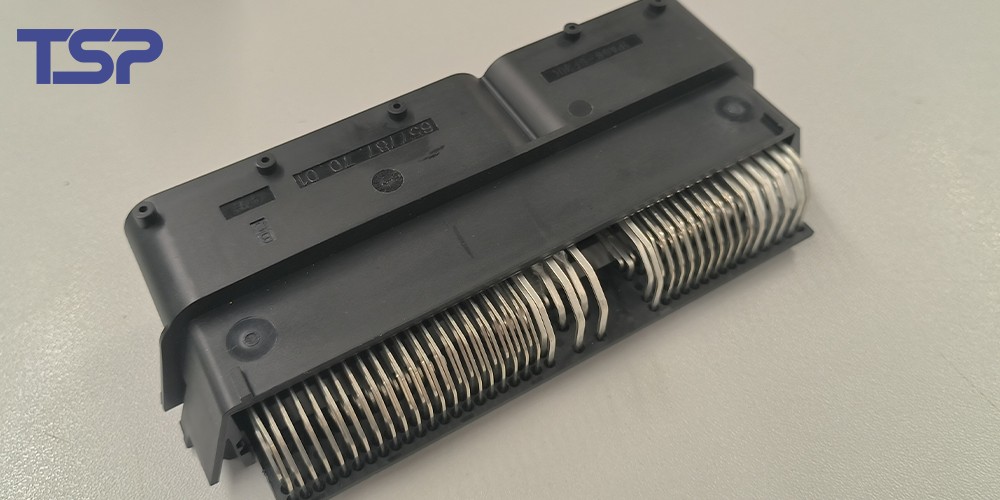

Q3: Is it possible to integrate inserts like metal contacts into injection-molded parts?

A: Yes. Insert molding allows metal parts or precision wiring interfaces to be molded directly into the component.

Why Custom Precision Injection Molding Matters for Wire Harness Manufacturers

Custom precision injection molds are not only about producing plastic parts—they are the foundation of reliable assemblies. For example, precision wire harnesses often rely on connectors, housings, and insulation components made with injection molding.

Accurate fit between the molded connector and the wire harness ensures signal integrity and safety.

Consistent dimensions reduce assembly time and lower rejection rates.

Durable molded components protect wire harnesses in demanding environments like automotive, medical, or industrial applications.

As a precision wire harness manufacturer, we understand that the performance of your final product depends on both high-quality molding and reliable wiring solutions. That’s why we combine advanced molding expertise with world-class harness design and production to deliver assemblies you can trust.

Conclusion

The advantages of custom precision injection mold—from precision, repeatability, and design flexibility to cost efficiency and sustainability—make it an essential process for modern manufacturing.

And when paired with precision-engineered wire harnesses, you gain a complete solution: plastic components and electrical systems working seamlessly together to ensure performance, reliability, and safety.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone