In the medical device industry, reliability, safety, and compliance are non-negotiable. Every component inside a medical system plays a critical role, and wire harnesses are no exception. While universal or off-the-shelf wire harnesses may appear to be a cost-effective option, they rarely meet the stringent demands of medical equipment.

This is why custom medical device wire harnesses are not just preferred, but essential.

Medical Devices Have Far More Demanding Requirements Than Standard Electronics

Medical devices operate in environments where precision and stability are vital. Whether used in diagnostic imaging, patient monitoring, or therapeutic equipment, even minor signal loss or connection failure can lead to inaccurate results or system downtime.

Compared with general industrial or consumer electronics, medical device wire harnesses must support:

Stable and low-loss signal transmission

Strong EMI and RFI shielding

Long service life under continuous operation

Compact and complex internal routing

Compliance with medical industry standards and regulations

Universal wire harnesses are designed for general applications and cannot consistently satisfy these requirements.

Common Problems When Using Universal Wire Harnesses in Medical Equipment

Universal wire harnesses are built for average needs, while medical devices are anything but average.

Typical issues include:

Mismatched connector types or sizes

Insufficient shielding leading to signal interference

Materials that cannot withstand repeated cleaning or sterilization

Poor flexibility and limited bend life

Difficulty passing medical compliance testing

In practice, these problems often lead to higher maintenance costs, increased failure rates, and potential regulatory risks.

How Custom Medical Wire Harnesses Solve These Challenges

Customization means the wire harness is designed specifically for the medical device, rather than forcing the device to adapt to a standard product.

A custom medical wire harness can provide:

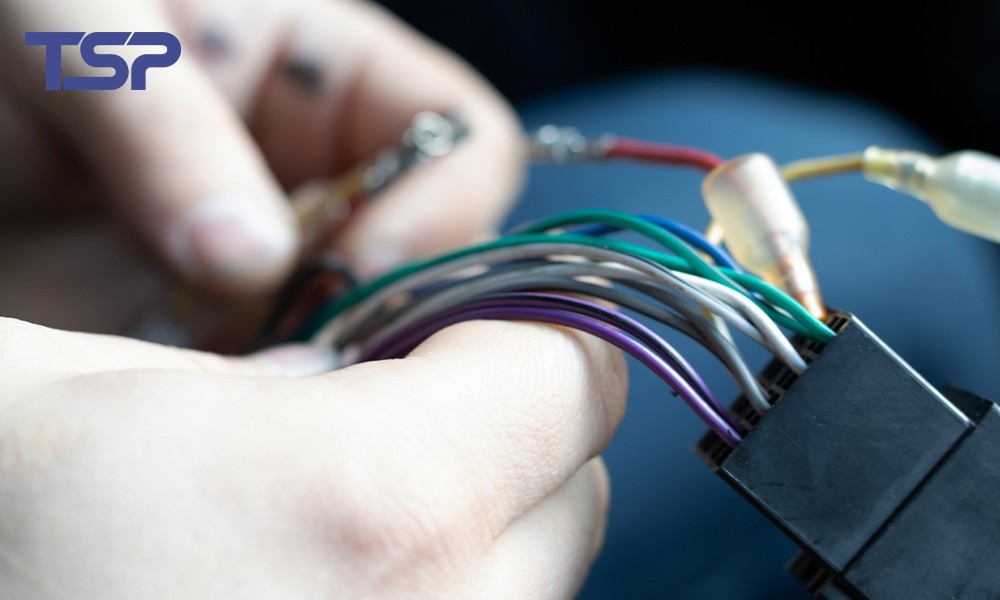

Precise Fit for Device Design

Wire length, branching, routing, and connector orientation are engineered to match the internal structure of the equipment, improving assembly efficiency and reducing installation errors.

Enhanced Signal Integrity and Noise Protection

Custom shielding and grounding solutions are designed according to the device’s signal sensitivity, ensuring reliable performance even in electrically noisy environments.

Materials Suitable for Medical Environments

Customized selection of insulation, jackets, and conductors ensures resistance to chemicals, cleaning agents, and long-term mechanical stress.

Compliance With Medical Standards

Custom designs allow early alignment with industry requirements such as ISO 13485, RoHS, and other applicable medical regulations, reducing certification risks later in the project.

The Business Value of Custom Wire Harnesses for Medical Device Manufacturers

From a manufacturer’s perspective, customization is not only a technical decision but also a strategic one.

Custom medical wire harnesses help manufacturers:

Reduce assembly and maintenance costs

Minimize field failures and warranty claims

Improve overall product quality and reliability

Strengthen brand credibility in regulated markets

Shorten time-to-market by avoiding redesigns

This is why many medical device companies now choose custom harness solutions at the early design stage, rather than treating wiring as an afterthought.

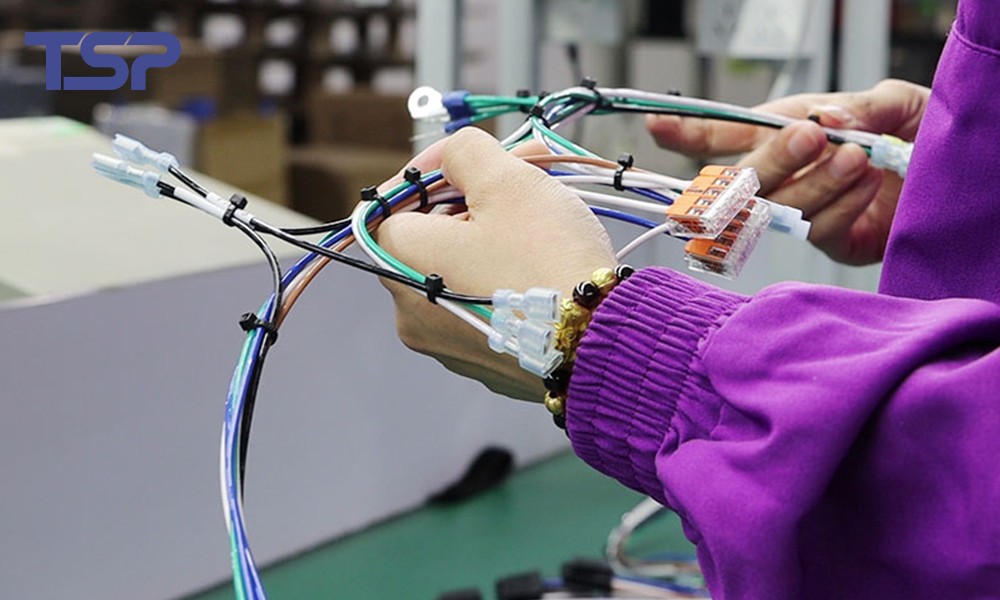

How tsp.cn Supports Custom Medical Wire Harness Solutions

As an experienced wire harness and cable assembly manufacturer, tsp.cn provides tailored wire harness solutions specifically for medical device applications.

Our capabilities include:

Custom medical wire harness and cable assembly design

Multi-core signal cables and shielded harness solutions

Specialized connectors and interface customization

Support from prototype to mass production

Strict quality control and process consistency

We understand that medical devices demand long-term reliability and consistency, which is why every solution is developed with safety, stability, and durability in mind.

Customization Is Not an Upgrade, It Is a Requirement

In medical equipment, a wire harness is not a simple accessory—it is a core functional component.

Choosing a universal harness may seem convenient, but it often introduces unnecessary risk.

Selecting a custom medical device wire harness means choosing:

Greater reliability

Better compliance readiness

Stronger overall system performance

For medical devices, customization is not a luxury—it is a necessity.

Contact tsp.cn for Your Custom Medical Wire Harness Solution

If you are developing or upgrading medical equipment and require a reliable custom medical wire harness manufacturer, tsp.cn is ready to support your project.

Our engineering team will work closely with you to deliver a wire harness solution tailored precisely to your application needs.