Mold design is a crucial aspect of manufacturing, essential for producing high-precision components across various industries, including automotive, electronics, medical, and aerospace. As products become more complex and demand for efficient production methods grows, mastering mold design is key to achieving optimal performance and product quality. This article explores essential mold design knowledge and provides a comprehensive guide to understanding key principles, best practices, and advanced techniques every mold expert should be familiar with to succeed in the ever-evolving field of mold manufacturing.

1. Core Principles of Mold Design

1.1 The Importance of Mold Design

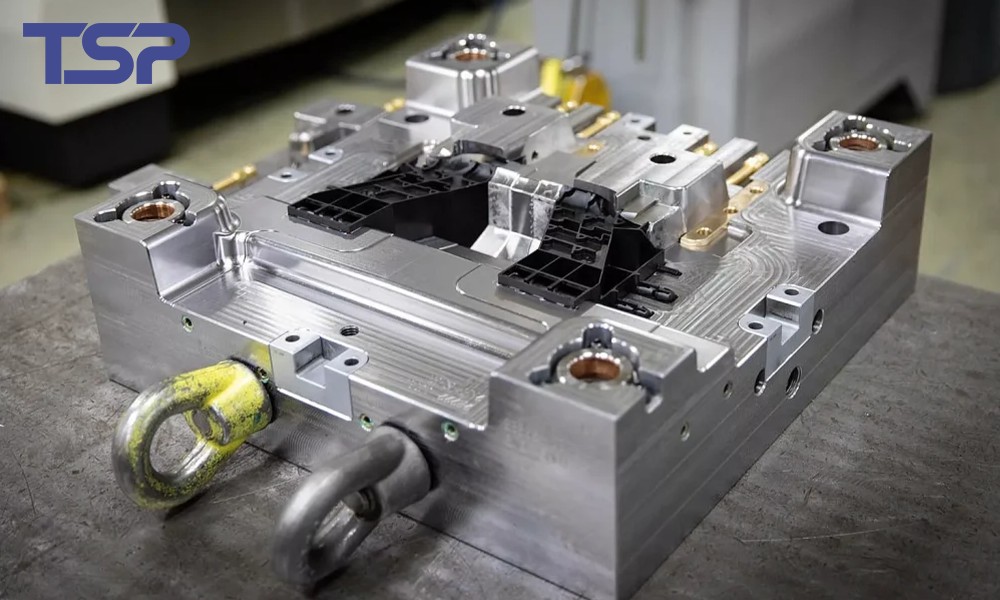

Mold design serves as the foundation for producing high-quality components. Whether it’s for plastic injection molding, die-casting, or compression molding, a well-designed mold ensures smooth production with minimal defects. The mold’s durability, precision, and ability to withstand harsh conditions determine the product’s overall quality and longevity. Mold design is not just about creating a mold but engineering the entire process to ensure consistent performance throughout the production cycle.

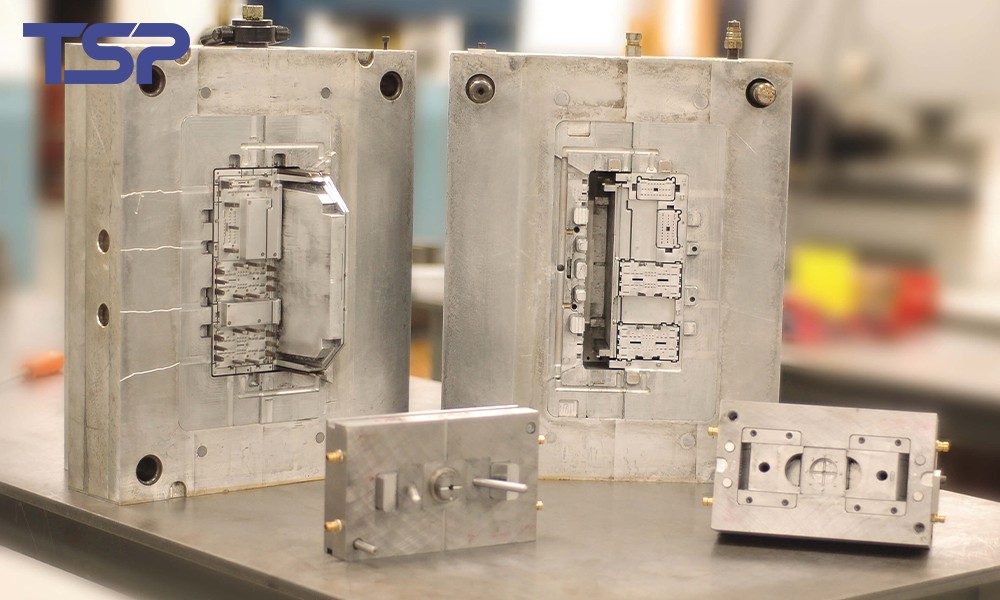

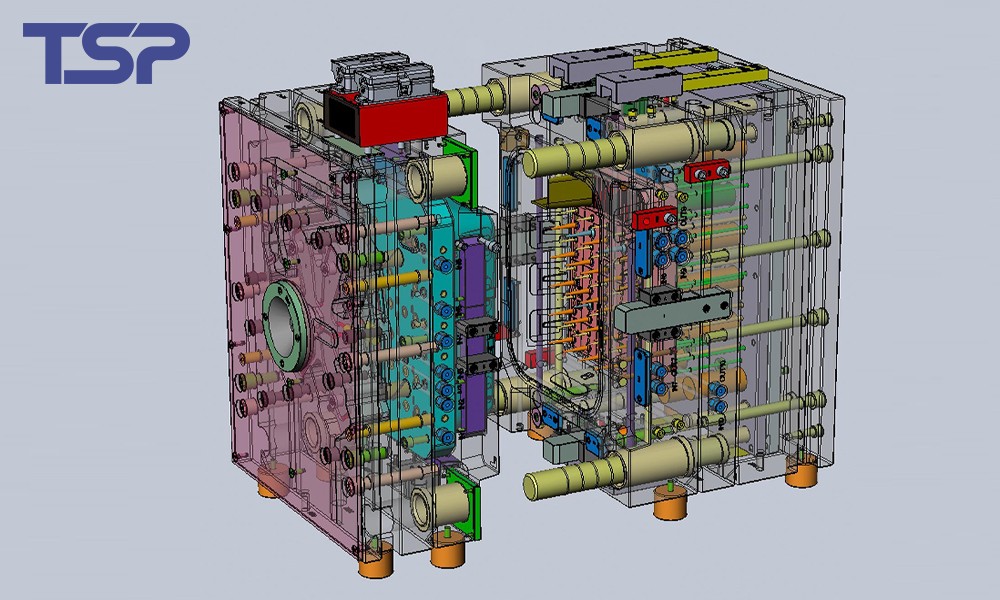

1.2 Key Components of Mold Design

Mold Cavity: The hollow space within the mold that defines the shape of the final part.

Ejection System: The mechanism that removes the molded part from the mold.

Cooling Channels: Efficient cooling channels reduce cycle time and prevent overheating of the mold.

Gate Design: The entry point for the material to flow into the cavity.

2. Material Selection for Mold Design

2.1 Choosing the Right Mold Materials

The material selected for the mold directly impacts its strength, durability, and performance. Common materials used for mold making include:

Tool Steel: Provides high strength, wear resistance, and ability to withstand high temperatures.

Aluminum: Lightweight and suitable for prototype molds or short production runs.

Beryllium Copper: Offers excellent thermal conductivity, often used for molds requiring quick cooling.

The key to successful mold design lies in selecting the right material based on factors like expected production volume, mold longevity, and heat management needs.

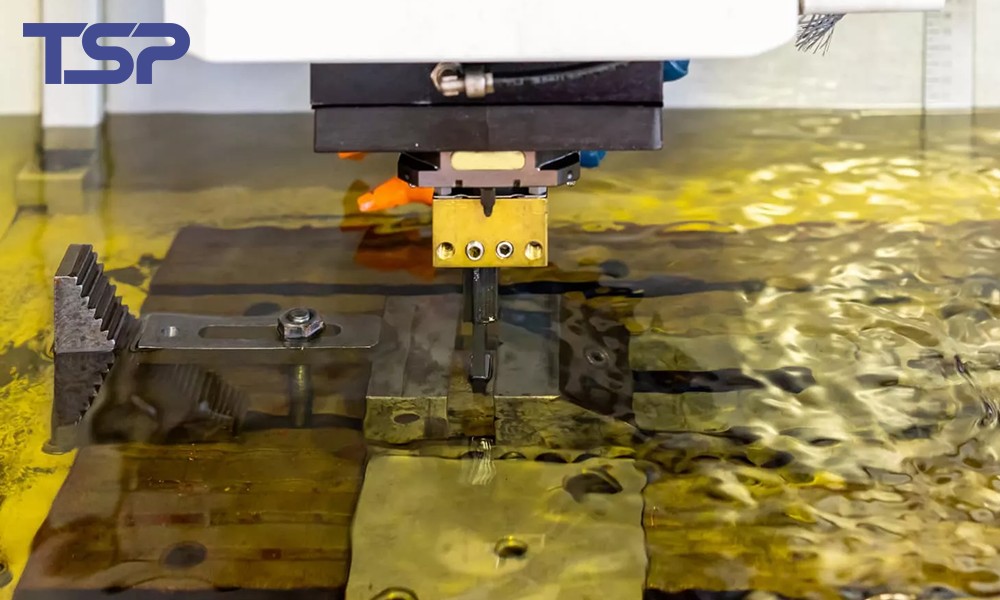

2.2 The Role of Steel Types

Steel is the most commonly used material for mold making. Among different steel types, Cr12, Cr12MoV, and S136 are popular choices. High-alloy steels provide excellent wear resistance, while low-alloy steels are cost-effective and suitable for simpler mold designs.

3. Advanced Mold Design Considerations

3.1 Mold Geometry and Tolerance

The geometry of the mold plays a crucial role in material flow and part quality. Precision tolerance control is essential in high-quality molds, as tight tolerances prevent defects such as misalignment, warping, and surface imperfections.

Thin Walls: Maintaining uniform wall thickness is key to preventing warping and ensuring consistent material flow.

Sharp Corners: Mold designs should avoid sharp corners, which create areas of stress concentration during molding.

Uniform Shrinkage: Shrinkage during cooling can affect mold performance. Proper geometry helps minimize the risk of dimensional variation.

3.2 Mold Simulation and Analysis

Advanced simulation software such as CAD (Computer-Aided Design) and CAE (Computer-Aided Engineering) tools can simulate material flow, cooling patterns, and mold behavior. These simulations help identify potential issues like flow imbalances or hot spots before the mold is even built, reducing costly production delays.

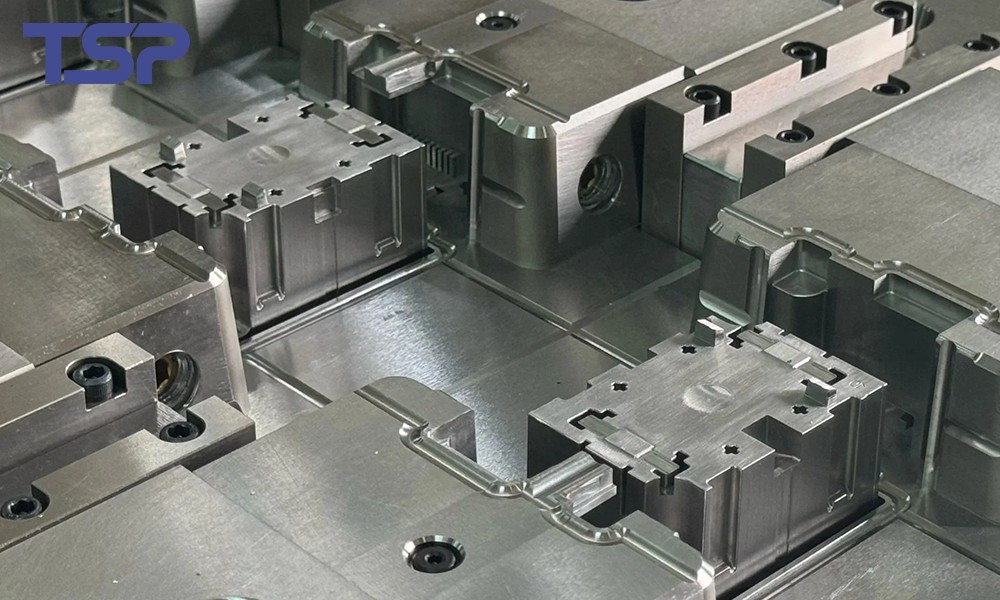

3.3 Multi-Cavity Mold Design

Multi-cavity molds are widely used for mass production, as they allow manufacturers to produce multiple parts per cycle, improving efficiency. However, designing multi-cavity molds requires careful attention to:

Uniform cooling: Ensuring each cavity cools at the same rate to prevent warping or unequal shrinkage.

Material flow balance: Even distribution of material across all cavities.

4. Common Mold Design Challenges

4.1 Managing Thermal Expansion

During heat treatment and production, molds undergo significant temperature changes. Thermal expansion can lead to warping or cracks if not managed properly. Techniques like preheating and temperature-controlled environments during molding help to mitigate thermal expansion.

4.2 Material Flow Issues

Mold design must ensure a uniform material flow. Issues such as short shots, delamination, or air pockets can occur if the mold isn’t properly balanced. Properly designed gates, runners, and venting systems can minimize these issues.

5. Maintenance and Durability of Molds

5.1 Regular Mold Maintenance

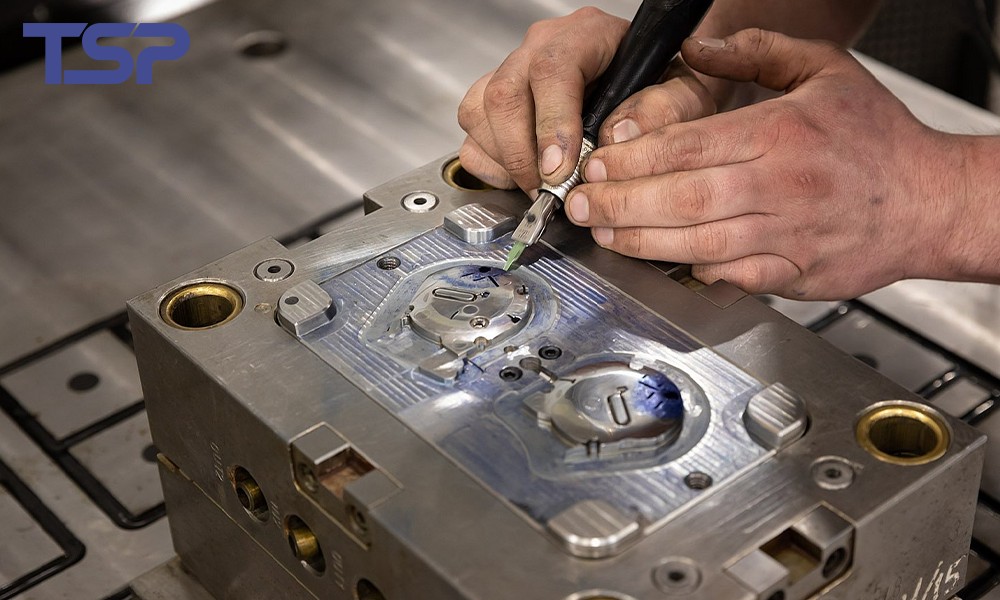

Proper maintenance is essential for mold longevity and production efficiency. Cleaning and lubricating molds regularly, as well as inspecting for cracks, wear, or misalignment, helps ensure their proper function. Regular maintenance can extend the mold’s life and reduce downtime in production.

5.2 Repairing and Refurbishing Molds

Even with regular maintenance, molds eventually experience wear. Refurbishing and repairing molds can restore their functionality and avoid the cost of building entirely new molds. Replacing worn components like ejector pins or cooling lines can prolong mold life and improve product quality.

6. Trends in Mold Design

6.1 Integration of 3D Printing in Mold Design

3D printing is increasingly used in mold making for rapid prototyping, allowing designers to test their ideas quickly before producing the final mold. 3D-printed molds can also be used for creating complex cooling channels that are difficult to achieve with traditional methods.

6.2 Smart Molds with Sensors

The next frontier in mold design involves the integration of smart sensors. These sensors can monitor variables like temperature, pressure, and material flow in real time, providing valuable data for optimizing the mold design and detecting issues early.

6.3 Sustainability in Mold Design

As sustainability becomes a more pressing concern, manufacturers are increasingly focusing on eco-friendly materials and energy-efficient molding processes. Innovations in sustainable molding practices are helping to reduce waste, energy consumption, and environmental impact.