As the electric vehicle (EV) industry accelerates, the safety and reliability of high-voltage systems have become top priorities for manufacturers and suppliers. Among all the critical components, the high-voltage harness (HV harness) acts as the electrical “lifeline” that connects the battery pack, inverter, and electric motor.

The insulation strength, fire-resistant performance, and leakage-current control of the HV harness directly determine not only the safety of the vehicle but also its long-term durability and performance.

This article explores the key international standards (UL, ISO, etc.), the design and material requirements, and the best safety practices for high-voltage wiring harnesses.

1. Why the HV Harness is Critical for EV Safety

In modern EVs, the electrical system often operates at 400 V, 800 V, or even higher. The HV harness must withstand extreme voltage, current, temperature, and vibration.

Any failure in insulation, shielding, or grounding may lead to electric shock, short circuit, or fire, resulting in system shutdown or vehicle recall.

Therefore, ensuring safety requires strict adherence to relevant international standards and comprehensive lifecycle quality control—from design and material selection to manufacturing, testing, and maintenance.

2. Standards Overview: Insulation, Fire Protection, and Leakage Current

2.1 Insulation Standards

Insulation materials must resist electrical breakdown, corona discharge, and thermal stress caused by high voltages. Standards such as UL 758, UL 62, and ISO 19642 specify insulation thickness, dielectric strength, and temperature resistance.

For 800 V or 1000 V systems, insulation design must include a wider safety margin and ensure proper clearance between conductors, housings, and grounded components.

Designers must also consider long-term factors like thermal aging, vibration fatigue, moisture, and chemical exposure to prevent insulation degradation.

2.2 Fire Protection Standards

If insulation or shielding fails, short circuits can cause arcing or ignition. Fire performance—flame retardancy, smoke density, and toxic gas emission—is therefore a critical safety factor.

Standards such as UL 94 V-0 and ISO 26262 set the benchmark for fire safety in automotive electrical components.

Material and structural design play key roles: fluoropolymer insulation, cross-linked polyethylene (XLPE), or high-temperature silicone jackets, combined with multi-layer shielding and separate circuit protection, greatly enhance fire resistance.

2.3 Leakage Current Standards

Leakage current refers to the small, unintended current that flows through insulation or shielding to the chassis or battery casing. Although typically low, it poses potential hazards if accumulated or combined with a fault condition.

Industry standards define maximum allowable leakage current and minimum insulation resistance under different conditions (dry, humid, or frozen).

Comprehensive testing—insulation resistance, dielectric withstand voltage, and leakage monitoring—is required to verify compliance.

3. HV Harness Design and Manufacturing Essentials

3.1 Material Selection

Insulation materials should provide high dielectric strength, thermal stability, and chemical resistance—commonly XLPE, silicone rubber, or fluoropolymers.

Outer jackets and shielding layers must resist heat, abrasion, water vapor, and corrosion.

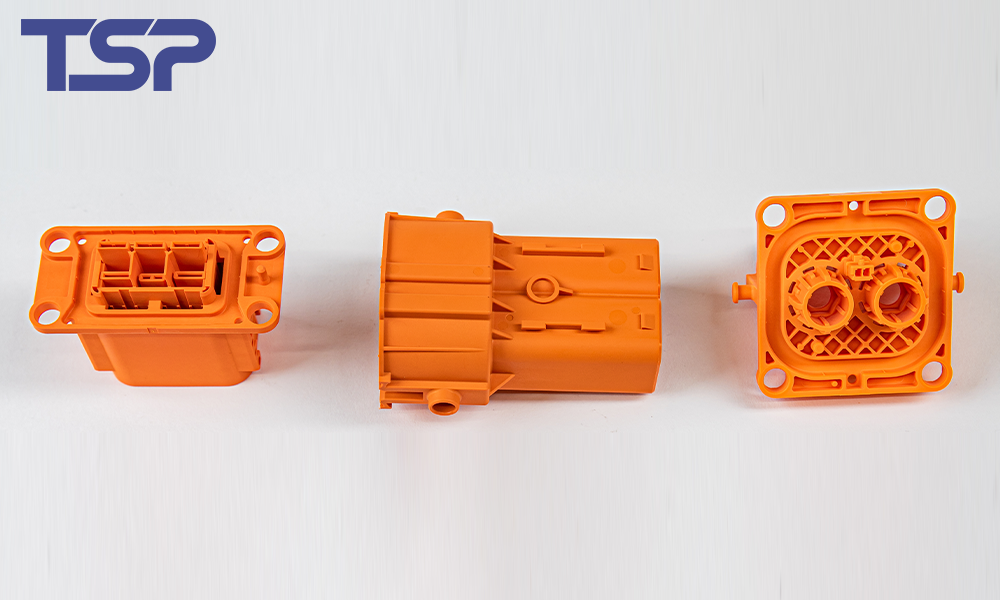

Connectors and terminals should use high-conductivity copper alloys with silver or tin plating, and feature secure mechanical locking mechanisms.

3.2 Structural Design

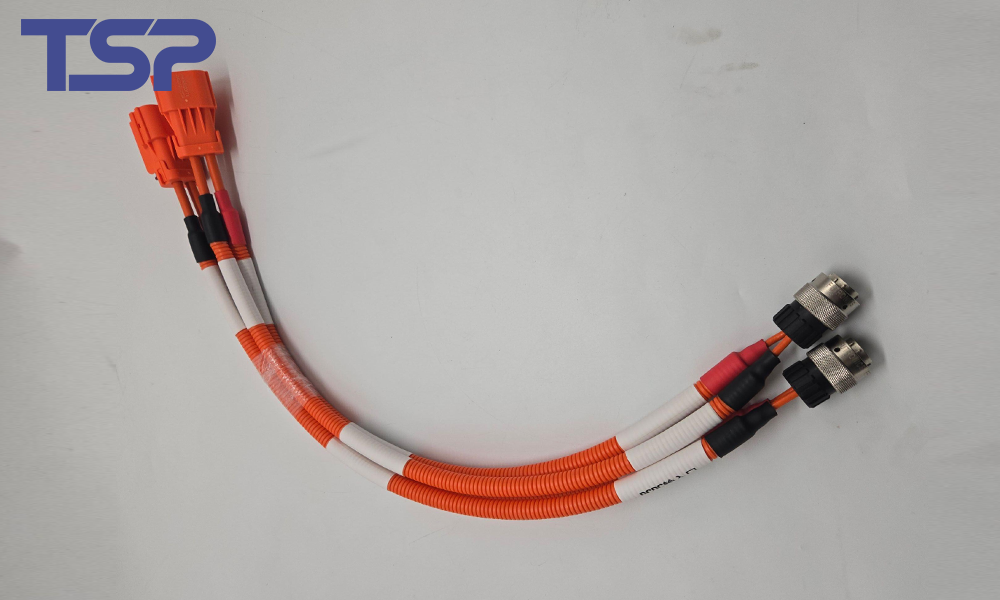

Proper routing minimizes electromagnetic interference (EMC) and ensures effective shielding.

Harnesses should be divided into zones and avoid bundling multiple high-current circuits together to reduce heat concentration.

Reinforcements such as strain reliefs, anti-vibration structures, and bend-radius protection are vital for durability.

3.3 Testing and Validation

Each harness must undergo dielectric withstand testing, insulation resistance testing, leakage current testing, and thermal cycling.

During vehicle integration, environmental tests—high temperature and humidity, salt spray, altitude, or freezing—ensure long-term reliability.

TSP provides full-process service covering design, DFM optimization, mold manufacturing, assembly, and comprehensive testing.

4. Safety Practices for Installation and Maintenance

Always disconnect and discharge the high-voltage system before maintenance.

Use certified insulated tools, and wear protective gloves, goggles, and clothing.

Inspect the harness regularly for cracks, discoloration, or overheating signs—replace damaged sections immediately.

Ensure harnesses are properly routed away from sharp edges, heat sources, and moving components, maintaining correct bend radius and secure mounting.

5. Why Choose TSP as Your HV Harness Partner

Over 26 years of expertise in electrical connection and harness technology.

Global manufacturing presence with facilities in Shanghai, Anhui, Mexico, and Morocco, ensuring fast delivery and localized service.

Full in-house capability: engineering design, DFM optimization, mold and tooling, insert/2-shot molding, harness assembly, and testing.

Compliance with global standards (UL, ISO, IATF) and extensive experience in new energy vehicle (NEV) projects.

TSP’s HV harnesses are designed to meet stringent requirements for insulation, fire safety, and leakage current control, providing customers with safer, more reliable EV solutions.

6. Call to Action

If you are developing or sourcing high-voltage harnesses for electric or hybrid vehicles, TSP is ready to support you.

Contact our engineering team for a free consultation or custom quote:

📩 sales@tsp.cn

🌐 Visit tsp.cn to learn more about our EV connection and harness solutions.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone