In modern electronics, automotive systems, medical devices, and smart equipment, reliable electrical connections are critical. At the heart of every secure connection lies the crimp — the bond between a wire and a terminal. Understanding how to evaluate crimp quality helps prevent failures, reduce downtime, and guarantee product reliability.

This guide explains how to judge the quality of wire harness crimps.

Why Crimp Quality Matters

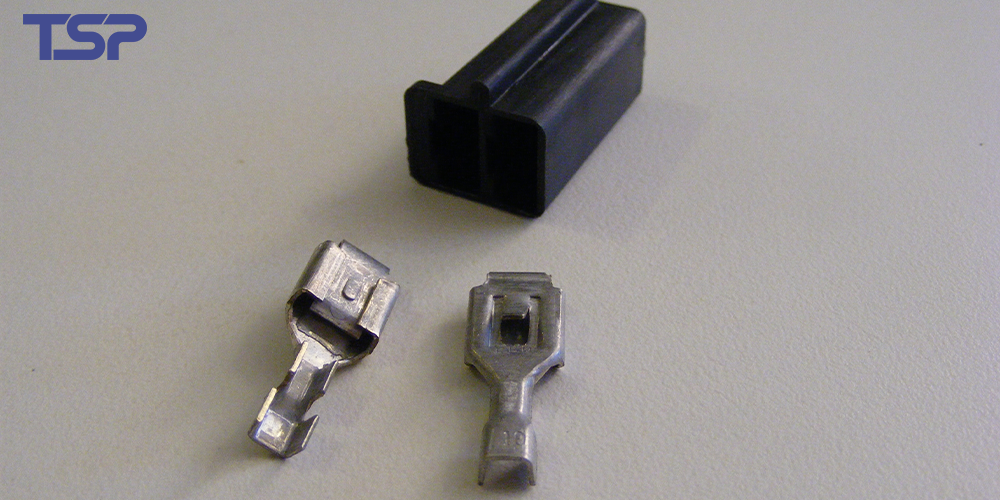

Crimping joins a wire to a terminal by compressing them together using specialized tools or machines.

A good crimp provides:

Strong mechanical strength that prevents the wire from pulling out.

Low electrical resistance for efficient current flow.

Long-term stability under vibration, heat, and humidity.

Poor crimping, on the other hand, can lead to unstable connections, overheating, or total circuit failure. For industries such as automotive or medical, even a single weak crimp can cause serious safety and reliability issues.

Key Indicators of a Good Crimp

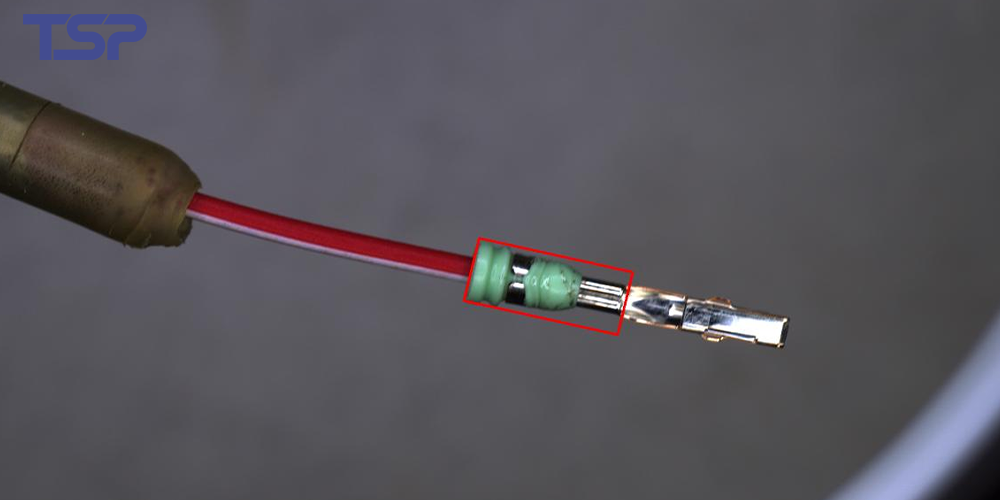

1. Correct Crimp Height and Compression

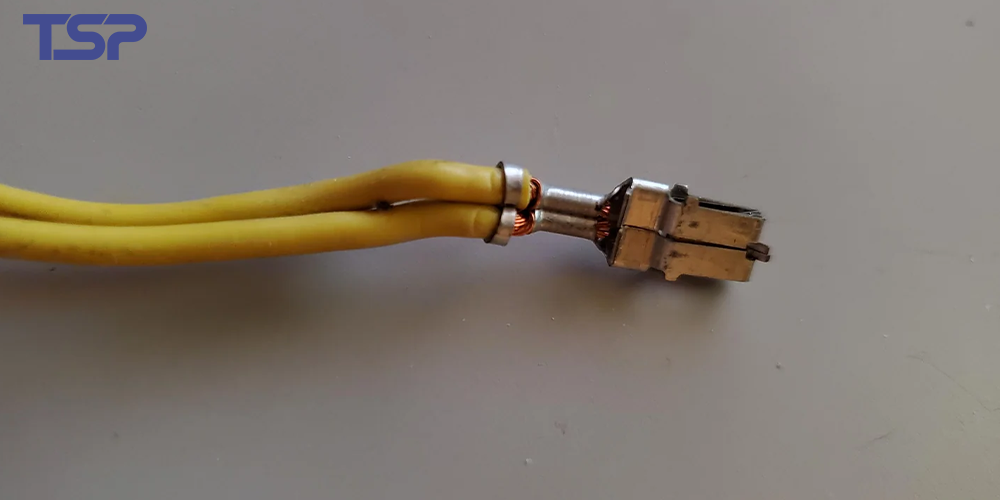

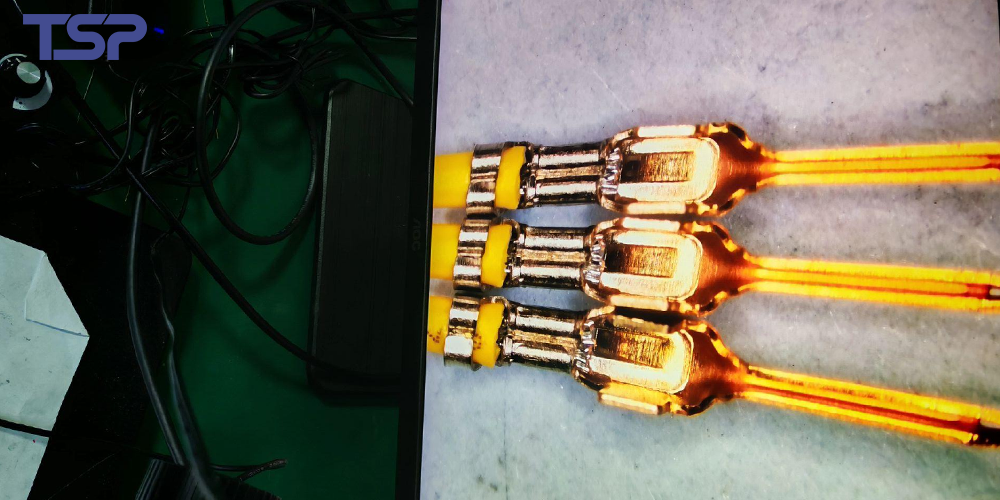

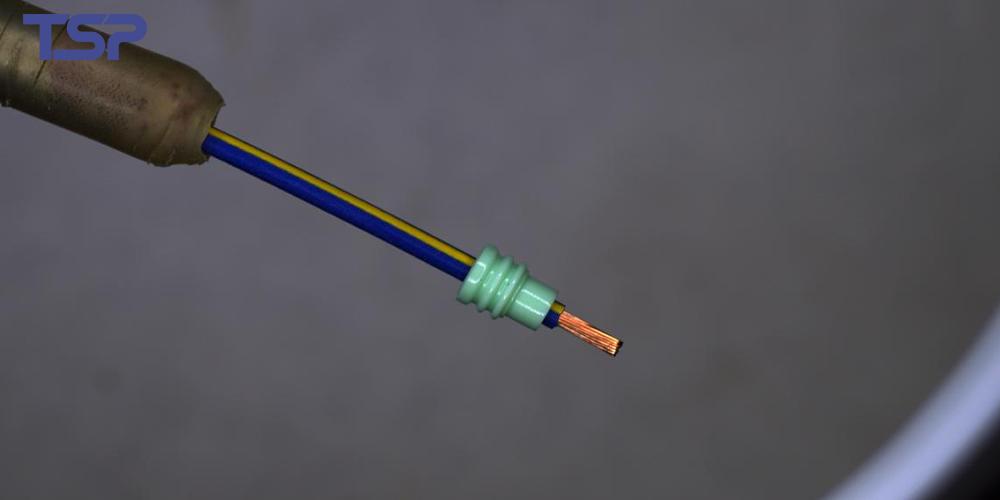

Proper crimp height and width ensure the wire strands and terminal barrel are tightly compressed without cutting or deforming the conductor.

If the crimp is too loose, it may cause high resistance or wire pull-out. Too tight, and the conductor strands may break or lose flexibility. Precise height control is one of the most reliable indicators of a stable crimp.

2. Pull-Out Strength

Pull-out or tensile testing measures how much force is required to separate the wire from the terminal.

A good crimp should withstand a specific pull force according to the wire size and terminal design. Consistent tensile strength confirms mechanical reliability and uniform production quality.

3. Electrical Conductivity

Crimps should maintain low contact resistance to ensure efficient current flow. Poor contact caused by incomplete compression or contamination increases heat generation and can shorten product life.

Monitoring electrical resistance in sample inspections helps identify any deviation early.

4. Visual Inspection

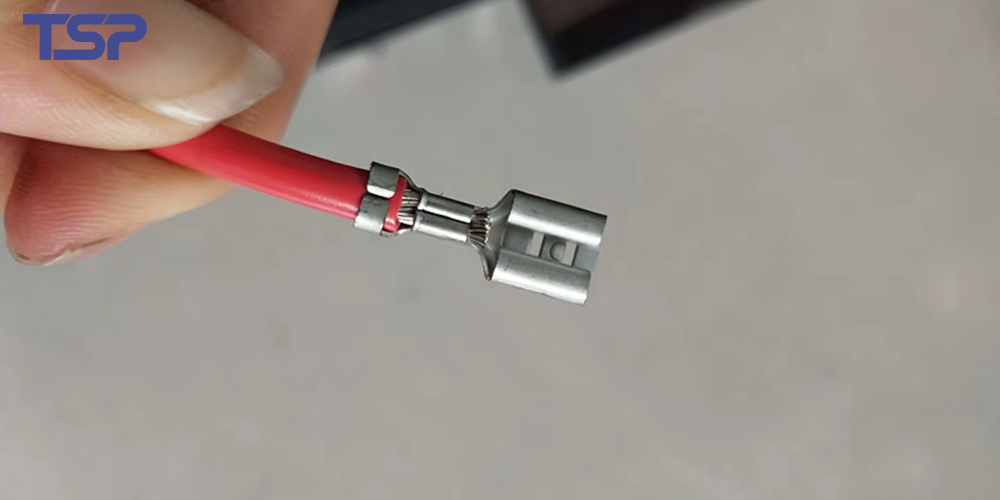

Visual checks remain a simple yet effective way to detect surface-level issues:

The wire strands should be fully inserted into the terminal.

There should be no bent, twisted, or cracked terminals.

The bell mouth and insulation support must be within acceptable size ranges.

No stray wire strands should be visible.

For high-precision assemblies, microscopic inspection is often used to verify internal compression and strand distribution.

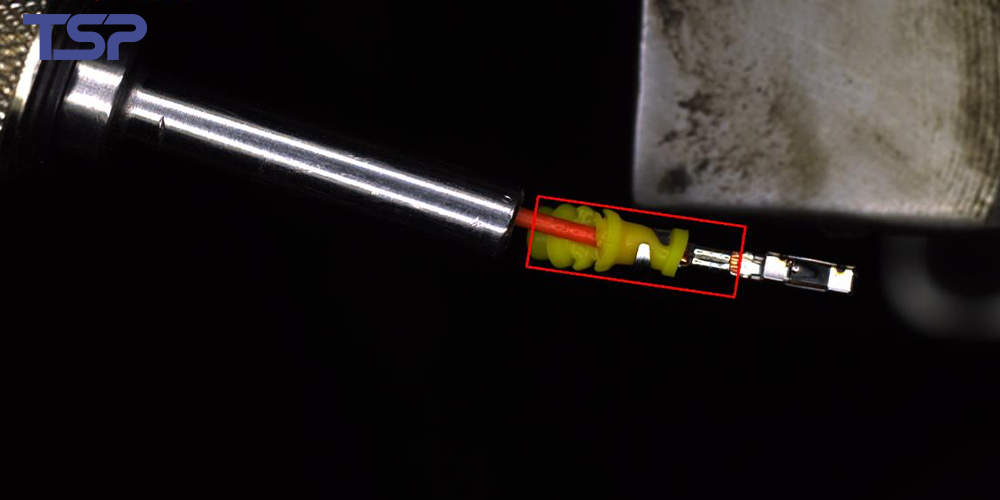

5. Process Control and Tool Calibration

Even the best design can fail without proper process control. Crimping tools and applicators must be matched to the terminal type and wire gauge, regularly calibrated, and maintained.

In automated production, monitoring crimp force or height during operation helps detect abnormalities in real time, ensuring each crimp meets the required standards.

6. Compliance with Industry Standards

Reliable crimps should conform to recognized industry standards such as IPC/WHMA-A-620 or automotive requirements like USCAR-21.

These standards define acceptable crimp height, pull-out force, deformation ratio, and inspection frequency — all crucial for consistent quality across production runs.

How to Evaluate a Supplier’s Crimping Capability

When sourcing wire harnesses or cable assemblies, you can judge a supplier’s professionalism by checking:

Whether they provide a Crimp Process Specification (CPS) detailing wire-to-terminal matching, target dimensions, and testing criteria.

Availability of sample inspection reports showing pull-out test results, crimp height data, and visual inspection photos.

A robust tool calibration and maintenance program with documented procedures.

Evidence of operator training and process audits to ensure consistent production quality.

By following these practices, you can avoid quality risks and choose a supplier capable of delivering high-reliability products.

With over 26 years of engineering and manufacturing experience, TSP Technology provides complete solutions — from precision stamping and molding to wire harness and connector assembly.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone