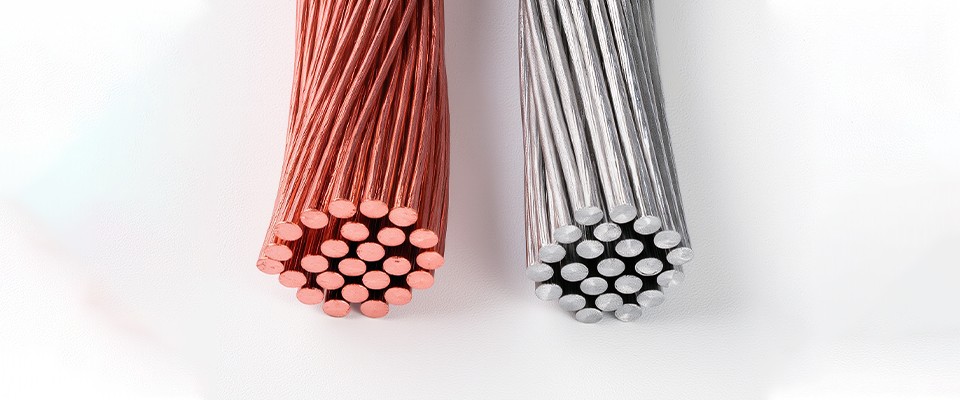

When designing modern wiring harnesses—especially for electric vehicles (EVs)—engineers often face one key question: Should we use copper or aluminum wires?

Both materials are widely used, but they serve different goals. Copper offers high conductivity and reliability, while aluminum brings clear advantages in cost and weight. Understanding these trade-offs helps you choose the right solution for your application.

1. Copper and Aluminum — What Makes Them Different

Copper wires are known for their excellent conductivity and strength. They handle high current with low resistance and minimal heat generation, which makes them a long-time favorite in both automotive and industrial wiring.

Aluminum wires, on the other hand, are about one-third the weight of copper. They are cheaper and easier to source, making them attractive for manufacturers who need to reduce both material costs and vehicle weight.

Copper = better electrical performance & durability

Aluminum = lighter weight & lower cost

2. Conductivity and Electrical Efficiency

Copper is still the benchmark for electrical performance. Its conductivity rating is 100% on the industry standard scale, while aluminum reaches around 60%.

That means an aluminum wire needs a larger cross-section to carry the same current as copper. In compact harnesses—like those found in EV battery systems—this larger size can be a design challenge.

However, with proper engineering, modern aluminum alloys and improved connectors can minimize these differences. Many automakers are already using aluminum in high-voltage cables where space is less limited.

Copper = higher efficiency, less heat buildup

Aluminum = larger size needed for same performance

3. Cost Comparison

Copper prices have remained high and can fluctuate with the global metals market. Aluminum is more abundant and generally costs 30–50% less per kilogram.

For manufacturers producing thousands of harnesses per year, this cost difference adds up quickly.

That said, the total cost of an aluminum harness includes extra considerations:

Thicker insulation or larger wire gauge

Special connectors and crimping tools

Additional testing for long-term reliability

So while aluminum saves on material, the overall system cost might be closer than it seems if additional design work is required.

4. Lightweighting Benefits

For EV manufacturers, weight reduction is not just a bonus—it’s a necessity. Every kilogram saved means longer driving range and better energy efficiency.

Because aluminum is about 67% lighter than copper, switching materials can lead to significant weight savings in large wiring systems. Even after increasing wire size to match current capacity, you can still expect around 40–50% weight reduction per harness segment.

This is why more EV brands are now using aluminum in battery cables, charging circuits, and main power lines, where the benefits of lightweighting outweigh the downsides of higher resistance.

5. Reliability and Durability

Copper’s biggest advantage lies in its mechanical strength and stability. It resists corrosion, vibration, and fatigue—conditions common in vehicles and heavy equipment.

Aluminum, while lighter, can be more sensitive to:

Surface oxidation (which affects conductivity)

Loosening at connection points due to thermal expansion

Lower tensile strength under mechanical stress

However, with modern connector design, surface treatment, and aluminum alloys, these issues are now manageable for most automotive applications.

6. How to Choose the Right Material

| Design Factor | Copper | Aluminum |

|---|---|---|

| Conductivity | Excellent (100%) | Moderate (~60%) |

| Weight | Heavy | ~⅓ of copper |

| Material Cost | High | Low |

| Thermal Stability | Excellent | Good with design care |

| Ease of Assembly | Easier | Needs special connectors |

| Durability | High | Moderate |

| Best Used For | High-current, space-tight systems | Long runs, high-voltage EV cables |

Use copper when: performance, reliability, and compact design are your top priorities.

Use aluminum when: lightweighting and cost efficiency are key, and your design allows larger conductor sizes.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone