In the world of precision connectivity, testing is the bridge between design and reliability. Whether in automotive, industrial automation, or medical equipment, the performance of a wire harness defines the safety and longevity of an entire system. At TSP, we believe that every connection deserves uncompromising precision — and testing is where that promise begins.

Understanding the Three Core Tests

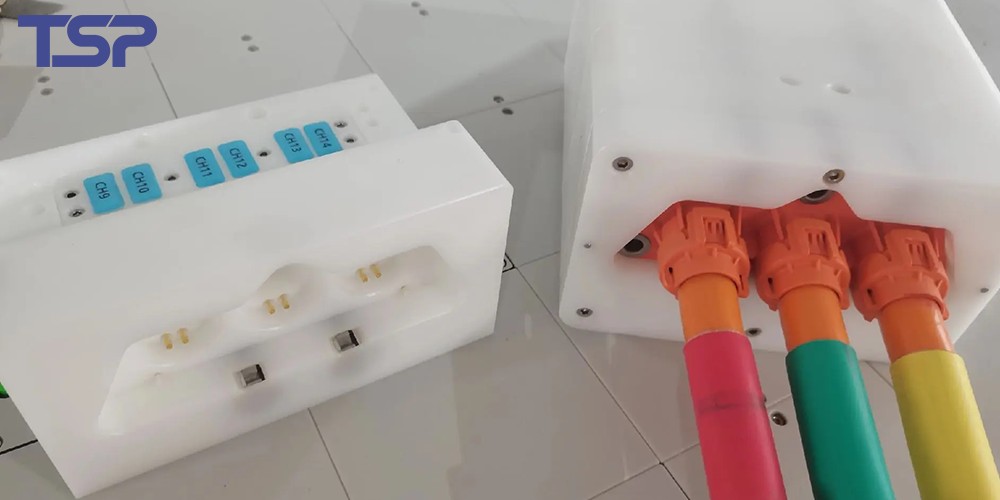

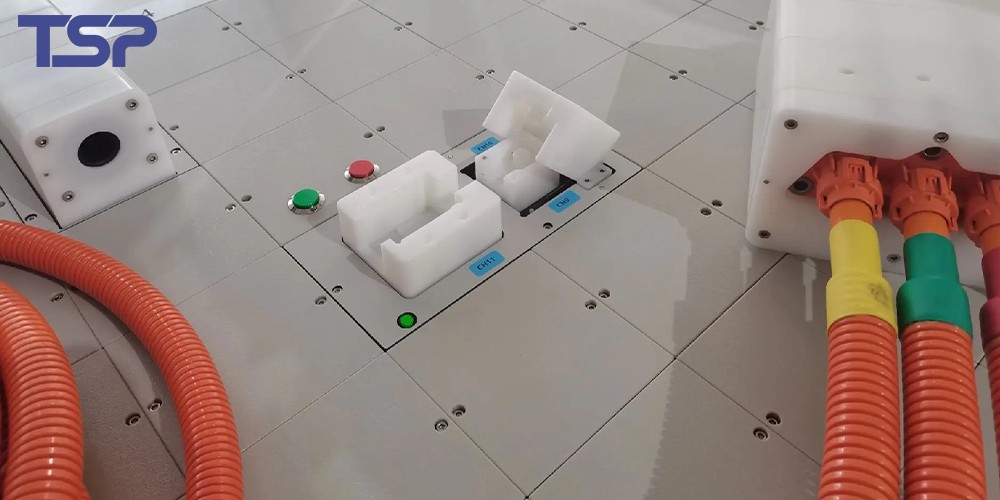

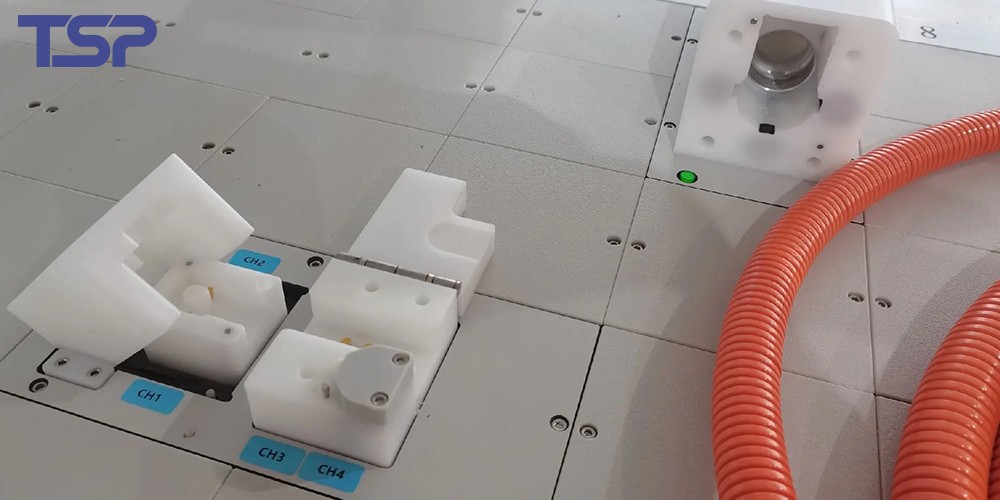

1. Continuity Testing

Continuity testing ensures every circuit is electrically complete. It detects open circuits, shorts, and miswires by sending a small current through each connection.

Modern testers automate this process, identifying faulty connections in seconds. At TSP, we integrate continuity validation into every harness production stage, guaranteeing zero-defect connections.

2. HiPot (High Potential) Testing

HiPot testing evaluates insulation integrity by applying a controlled high voltage between conductors. This verifies that no breakdown occurs under stress — essential for automotive ECUs, industrial sensors, and medical devices.

TSP’s test systems perform both AC and DC HiPot checks under tightly controlled conditions, ensuring safety and compliance with IEC and UL standards.

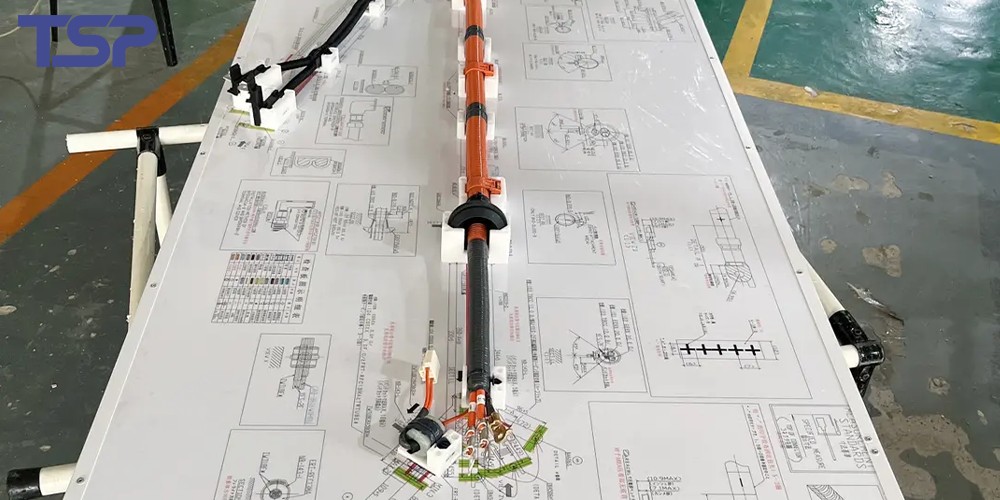

3. Pull Test

Mechanical strength is as vital as electrical integrity. Pull testing measures the force required to separate terminals from wires, ensuring crimp quality and mechanical reliability.

Our automated pull-test machines record real-time data to maintain consistent production quality across millions of units.

Why Proper Testing Matters

Safety and Compliance: Testing prevents short circuits, fire hazards, and system failures.

Reliability and Performance: Ensures stable signal transmission even under vibration, moisture, or temperature extremes.

Brand Reputation: Products with proven reliability strengthen customer trust and long-term partnerships.

Best Practices for Effective Harness Testing

Standardize Test Procedures – Use digital netlists and automated testers to eliminate human error.

Combine Electrical and Mechanical Tests – Integrating continuity, HiPot, and pull testing ensures 360° quality control.

Implement Traceability – Record every test result for future reference and quality audits.

Adapt to Application Requirements – EV connectors, industrial robots, and smart home devices all demand unique test voltages, wire gauges, and tolerances.

Choose a Proven Partner – Work with manufacturers who invest in testing automation and have multi-industry expertise.

How TSP Ensures Excellence

With over 26 years of experience in precision tooling, stamping, molding, and harness assembly.

From automotive connectors to medical wire harnesses, industrial sensors, and communication modules, we tailor every testing protocol to the customer’s design intent and operating environment.

Your Connection to Quality

Testing is more than a process — it’s a promise. When you choose TSP, you partner with a team committed to delivering flawless connectivity solutions backed by data, precision, and trust.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone