In the medical industry, every connection matters. A single wiring fault can compromise patient safety or device performance. That’s why medical wire harness design and certification are not just technical requirements—they are a matter of life and reliability.

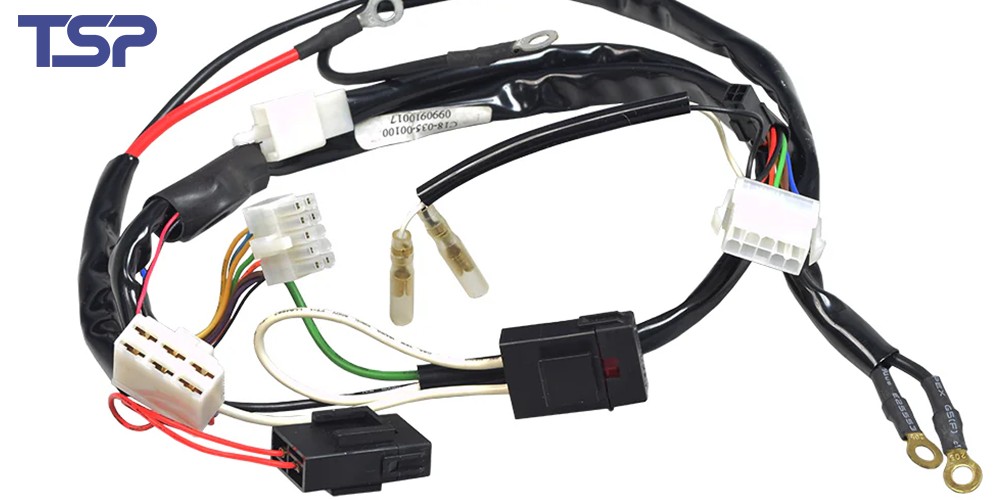

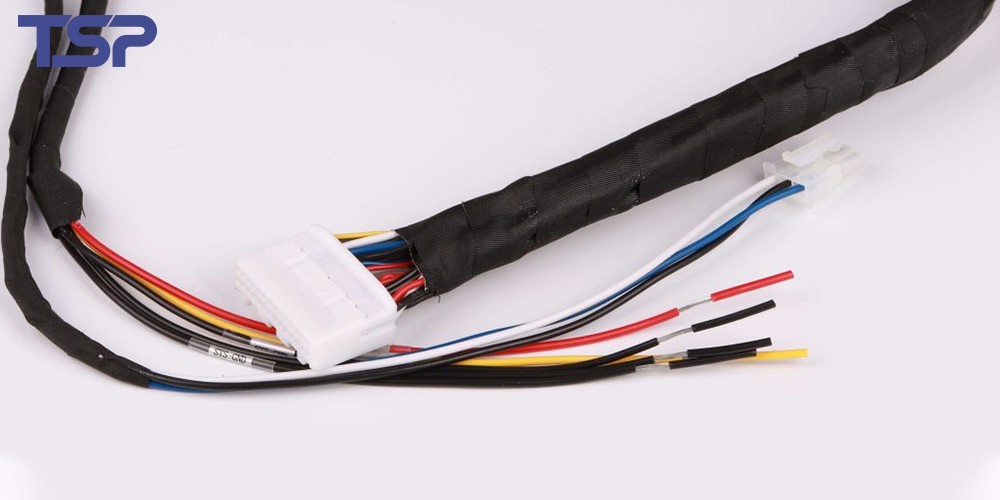

With more than 26 years of precision manufacturing experience, TSP provides fully compliant, high-reliability wire harness and cable assembly solutions trusted by global OEMs in healthcare, diagnostics, and medical device manufacturing.

Understanding Medical Wire Harnesses

A medical wire harness organizes and protects multiple wires or cables that transmit power and signals within medical equipment such as imaging systems, ventilators, surgical robots, and patient monitoring devices.

Unlike industrial harnesses, medical versions must withstand:

Sterilization processes (autoclave, EtO, gamma)

Frequent flexing and cleaning

Biocompatibility and safety regulations

Traceability and documentation requirements

Each of these factors makes certification and compliance crucial from design through production.

Key Certifications and Standards for Medical Wire Harnesses

ISO 13485 – Medical Device Quality Management System

Ensures consistent quality and traceability in manufacturing.

A must for any supplier in the medical device supply chain.

UL and CSA Safety Certifications

Verifies material safety, insulation performance, and flammability resistance.

RoHS and REACH Compliance

Guarantees restriction of hazardous substances and chemical safety.

IPC/WHMA-A-620

Defines acceptability standards for wire harness assemblies.

FDA and CE Requirements

For devices entering U.S. or EU markets, ensuring electrical safety and biocompatibility compliance.

ISO 9001 and ISO 14001

Reinforces TSP’s integrated commitment to quality and environmental management.

At TSP, we combine these standards into a single, robust production workflow—backed by meticulous testing and validation.

Why Certification Matters for OEMs

Patient Safety – Certified harnesses minimize electrical faults and contamination risk.

Global Market Access – Compliance enables export to regulated regions such as the EU, U.S., and Japan.

Design Traceability – Each component can be tracked from raw material to finished device.

Reliability Under Stress – Certified materials maintain integrity after sterilization or long-term use.

Partnering with a certified manufacturer ensures your product can pass both regulatory review and long-term operational demands.

How to Design a Certified Medical Wire Harness

Early Collaboration – Involve your harness supplier (TSP) at the design stage to ensure material and process compliance.

Select Medical-Grade Materials – Use biocompatible insulation, high-purity copper, and low-outgassing overmolds.

Plan for Sterilization – Choose materials and seals that survive repeated autoclaving.

Define Documentation Flow – Maintain DHR (Device History Record) and DMR (Device Master Record) for traceability.

Validate and Test – Perform electrical continuity, insulation resistance, flex-life, and environmental stress testing.

TSP’s engineering team offers DFM (Design for Manufacturability) and DFT (Design for Testability) support to shorten validation time and accelerate certification.

TSP’s Advantage in Medical Wire Harness Manufacturing

Comprehensive in-house capabilities: tool & mold design, metal stamping, insert molding, wire harness assembly, and testing—all under one roof.

Cleanroom assembly environment for sensitive medical products.

Certified to ISO 9001, ISO 14001, and IATF 16949, with processes aligned to ISO 13485 and IPC/WHMA-A-620.

Custom engineering support from prototype to mass production.

Global footprint – facilities in China, Mexico, and Morocco ensure flexible supply and local support.

By integrating tooling, molding, and assembly, TSP minimizes supply chain risks while maintaining world-class quality and cost efficiency.

Applications of TSP Medical Harness Solutions

Patient monitoring and imaging systems

Diagnostic analyzers

Surgical and robotic instruments

Life-support and respiratory equipment

Portable and wearable healthcare devices

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone