When it comes to metal casting, precision is often the most important factor engineers and manufacturers consider. Whether you are designing automotive components, aerospace parts, or high-performance electrical connectors, choosing the right casting method can make the difference between a flawless product and costly rework.

Two of the most common casting processes—investment casting and permanent mold casting—are often compared for their accuracy, surface finish, and cost efficiency. But which method is truly more precise?

Understanding the Two Casting Processes

Investment Casting (Lost Wax Casting)

Uses a wax pattern coated in ceramic slurry to create a mold.

Once hardened, the wax is melted away, leaving a cavity for molten metal.

Each mold is expendable, meaning it’s used only once.

Capable of producing highly complex shapes with excellent surface detail.

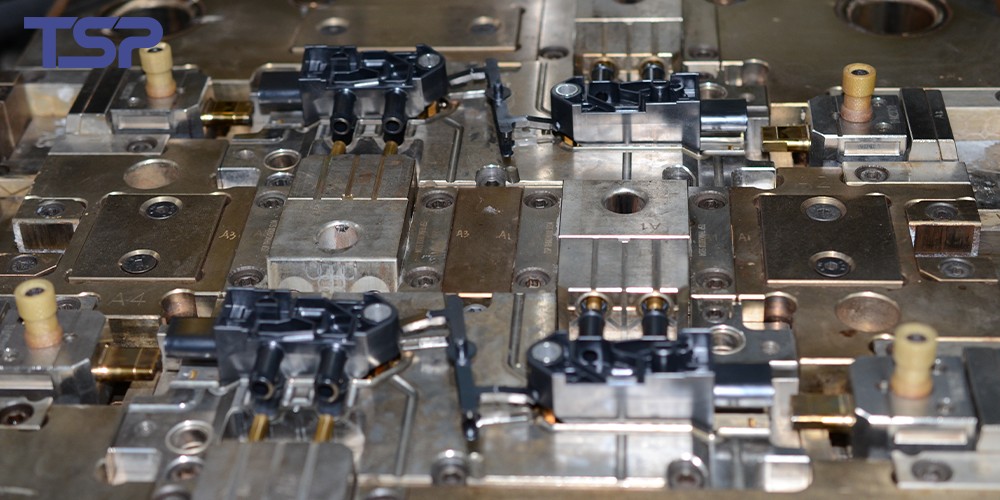

Permanent Mold Casting

Uses reusable metal molds, often made from steel or iron.

Molten metal is poured or injected into the mold under gravity or pressure.

The mold can be used hundreds or even thousands of times, making it efficient for medium-to-high production volumes.

Delivers consistent dimensions across multiple parts.

Precision Comparison: Which Method Is More Accurate?

Dimensional Accuracy

Investment Casting:

Tolerances can reach ±0.1 mm to ±0.2 mm depending on the part size.

Particularly effective for thin walls and intricate geometries.

Permanent Mold Casting:

Typical tolerances are ±0.25 mm to ±0.5 mm, slightly less precise.

Best for parts with simpler shapes but requiring uniformity over many units.

✅ Winner: Investment Casting – superior accuracy, especially for complex or small components.

Surface Finish

Investment Casting:

Produces a smooth finish (Ra 1.6–3.2 µm) without much post-processing.

Ideal when cosmetic appearance or reduced machining is critical.

Permanent Mold Casting:

Surface finish is generally rougher (Ra 3.2–6.3 µm).

Often requires secondary machining or polishing.

✅ Winner: Investment Casting – finer surface detail and smoother finish.

Geometric Complexity

Investment Casting:

Can achieve thin walls, internal cavities, intricate features, and undercuts.

Flexible for parts like turbine blades, aerospace brackets, or electrical connector housings.

Permanent Mold Casting:

Limited in geometry due to the rigidity of reusable molds.

Best suited for simpler, heavier-walled parts.

✅ Winner: Investment Casting – unmatched capability for complex geometries.

Production Consistency

Investment Casting:

High precision per part, but since each mold is single-use, variation may occur across large batches.

Permanent Mold Casting:

Extremely consistent part-to-part accuracy due to reusable molds.

Better for applications requiring long runs of identical parts.

✅ Winner: Permanent Mold Casting – better repeatability in medium-to-high volume production.

So, Which Is More Precise?

If we define precision as dimensional accuracy, surface finish, and complexity, then investment casting is generally more precise than permanent mold casting. It allows manufacturers to produce parts with tighter tolerances, smoother finishes, and more intricate details.

However, if production consistency across thousands of units is your priority, permanent mold casting holds the advantage.

Choosing the Right Process

Choose Investment Casting If:

You need high precision for complex or detailed designs.

Surface finish is important, and you want to minimize machining.

Your project involves low-to-medium production runs.

Choose Permanent Mold Casting If:

Your design is relatively simple but requires high consistency.

You need medium-to-high production volumes.

Tooling investment is acceptable for long-term cost savings.

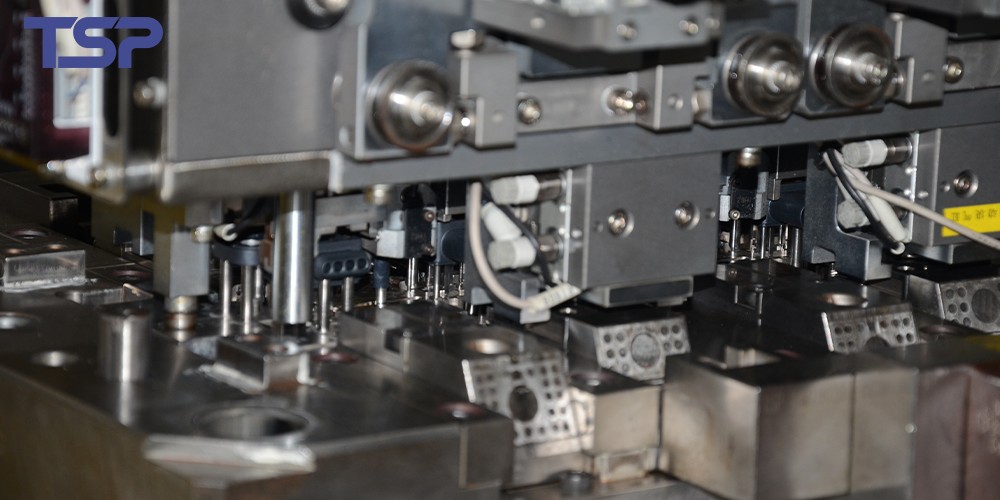

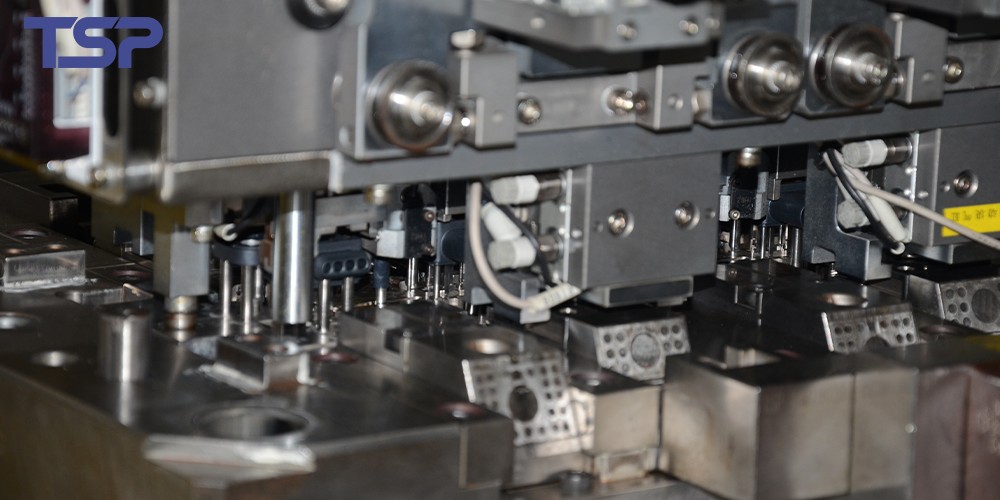

How This Relates to Precision Wiring Harness Components

As a precision wiring harness manufacturer, we understand that the performance of your electrical systems depends not only on the harness itself but also on the quality of cast connectors, terminals, and housings used in the assembly.

When complex connector housings or brackets are required, investment casting ensures tighter tolerances and smoother finishes.

For large-volume applications, permanent mold casting delivers consistency and durability.

By combining the right casting process with our expertise in precision wiring harness manufacturing, we ensure that every assembly meets the highest standards of reliability, accuracy, and durability.

Final Thoughts

So, what is more precise: investment casting or permanent mold casting?

➡️ Investment casting is more precise overall, especially when it comes to complex shapes and fine tolerances.

But the best choice depends on your project’s design requirements, batch size, and cost considerations.

At TSP, we specialize in precision wiring harnesses and work closely with our partners to ensure every component—from the cast housing to the finished harness—meets the strictest quality standards.

👉 If you’re looking for high-precision harness solutions for automotive, aerospace, medical, or industrial applications, contact us today.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone