When people ask “How long does a wiring harness last?”, they usually expect a simple number—5 years, 10 years, or the entire life of a vehicle. The truth is more complex. A wiring harness is designed to be durable, but its actual lifespan depends on multiple factors such as material quality, environmental conditions, and how well it was manufactured.

In this article, we’ll break down the average lifespan of a wiring harness, the factors that shorten or extend it, the signs of deterioration, and why choosing a precision-engineered harness matters for long-term reliability.

How Long Does a Wiring Harness Last?

Most wiring harnesses are designed to last as long as the equipment or vehicle itself. In ideal conditions, a harness can function reliably for 15–20 years or more. However, many sources note that 5–10 years is when issues may start appearing, especially in harsh environments.

Passenger cars: 10–15 years, often matching the vehicle’s life span.

Heavy equipment / off-road vehicles: 5–8 years due to vibration, dust, and extreme weather.

Marine / high-moisture environments: 3–7 years unless special waterproof harnesses are used.

So, the answer is: a wiring harness can last the entire life of a vehicle, but real-world conditions often reduce its effective lifespan.

Key Factors That Affect Lifespan

A harness doesn’t just fail because of age. Here are the most common reasons:

Material Quality

Insulation type (PVC vs cross-linked polyethylene vs silicone).

Connector plating (tin vs gold vs nickel).

Shielding and protective tubing.

Environmental Conditions

Heat: Engine compartments can exceed 120°C, accelerating insulation breakdown.

Moisture & Salt: Corrosion weakens terminals.

Chemicals: Oils and solvents can degrade insulation.

Mechanical Stress

Constant vibration.

Bending and friction against sharp surfaces.

Poorly secured harnesses rattling inside the engine bay.

Installation & Design

Poor crimping or soldering.

Incorrect routing, leaving wires exposed to heat or abrasion.

Low-quality connectors or terminals.

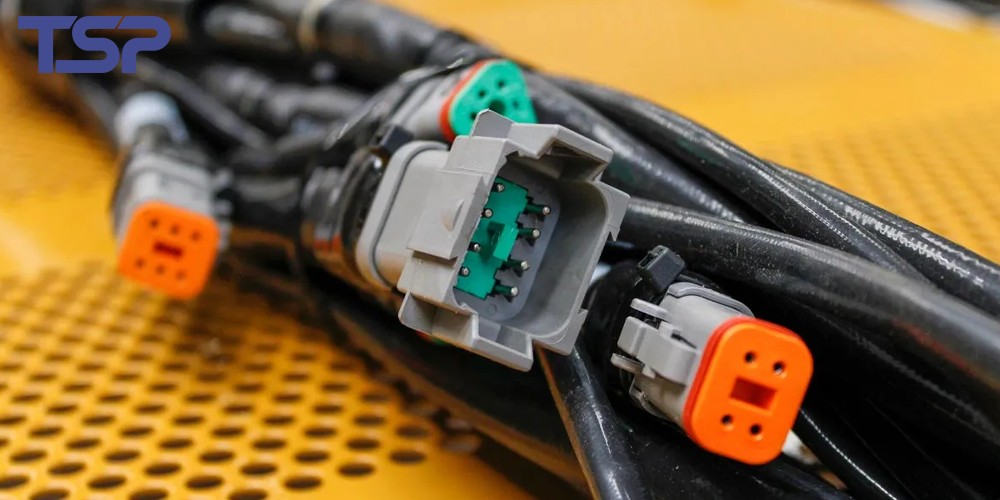

Signs That a Wiring Harness Is Failing

Before complete failure, most harnesses show warning signs:

Intermittent electrical problems (lights flickering, sensors malfunctioning).

Visible cracks, brittleness, or melting of insulation.

Corroded or discolored connectors.

Short circuits or blown fuses happening repeatedly.

Rodent damage (common in stored vehicles).

If these appear, inspection and partial repair may extend life, but full replacement is sometimes the only safe option.

Can You Repair or Should You Replace?

Repairable cases: Localized corrosion, one or two damaged connectors, minor insulation wear.

Replacement needed: Multiple failures, severe corrosion, heat-damaged harnesses, or safety-critical systems.

Professional repair requires the correct wire gauge, OEM-spec connectors, and proper sealing methods like heat-shrink tubing. Improper fixes (like wrapping with tape or using cheap quick-connects) can cause bigger problems later.

How to Extend the Life of Your Wiring Harness

Keep connectors clean and sealed.

Secure harnesses away from sharp edges and moving parts.

Use protective conduits and heat shields in high-temperature zones.

Choose precision-manufactured harnesses that are built with high-grade insulation, corrosion-resistant terminals, and strict quality control.

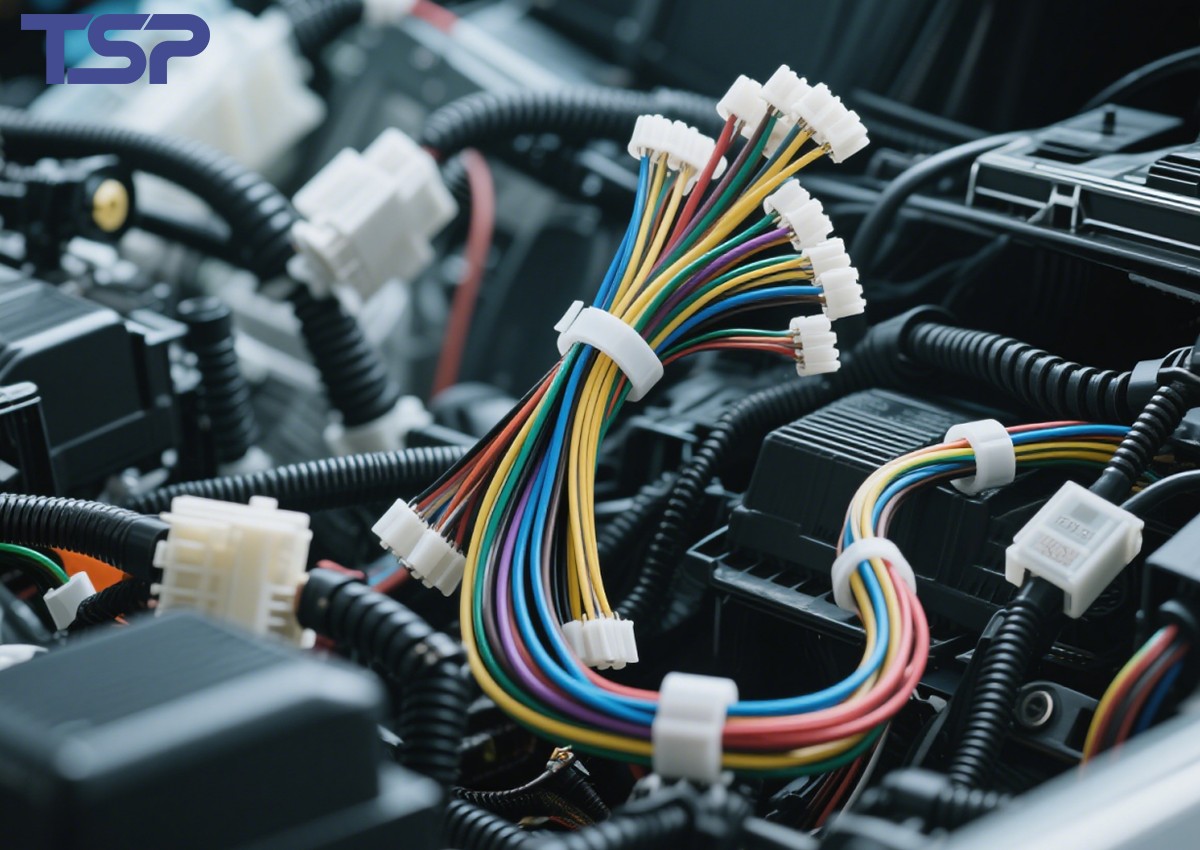

Why Precision Manufacturing Matters

A wiring harness is not just a bundle of wires—it’s the nervous system of your car or machine. Small differences in design and manufacturing quality can add or subtract years from its lifespan.

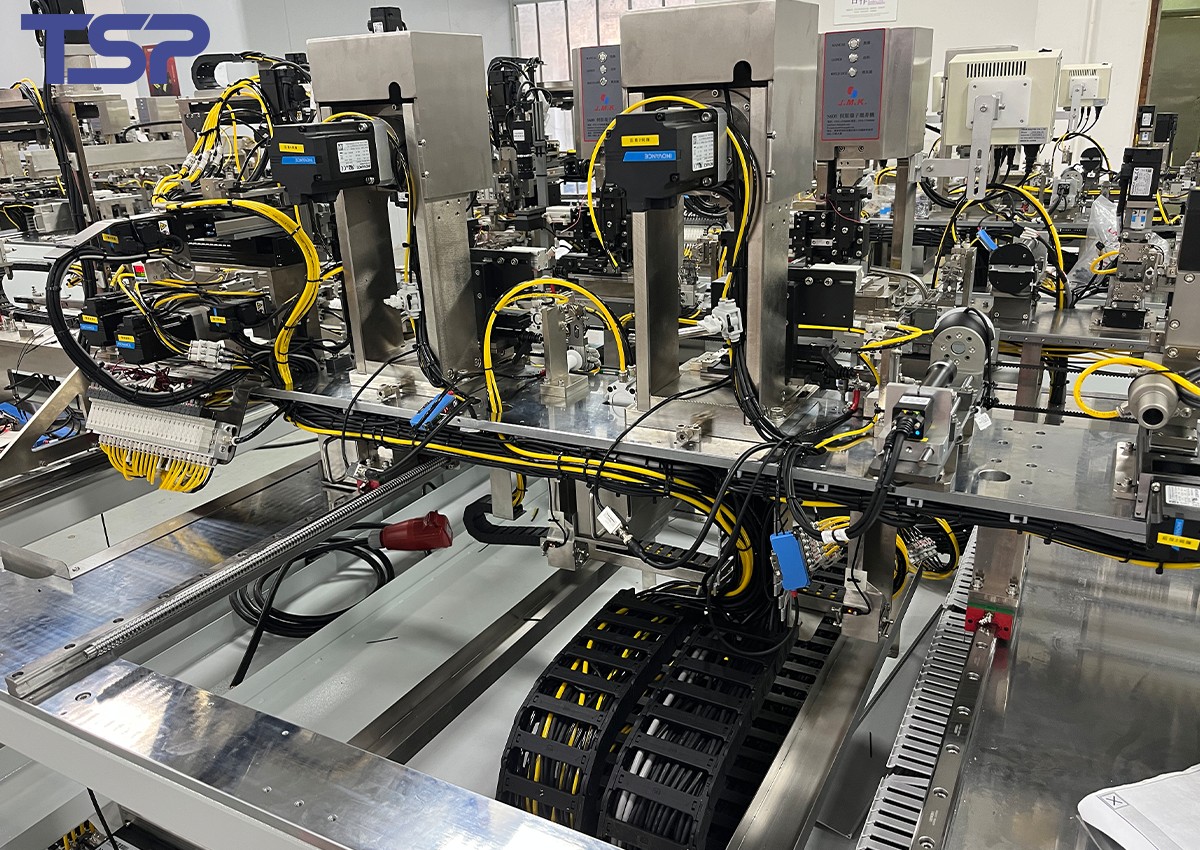

As a precision wiring harness manufacturer, we use:

High-temperature-resistant insulation materials for engine compartments.

Custom connector solutions with anti-corrosion plating.

Automated crimping and assembly to eliminate human error.

Strict testing (continuity, pull-force, salt-spray, vibration) to ensure reliability.

This means our harnesses are engineered not just to last, but to outperform standard harnesses in harsh conditions.

Conclusion

So, how long does a wiring harness last?

In theory: the life of your car or equipment.

In practice: anywhere from 5 to 20 years, depending on materials, environment, and quality.

The best way to ensure long service life is simple: start with a precision-engineered harness built to withstand the conditions you operate in.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone