In electric vehicles (EVs) and hybrid systems, high-voltage (HV) wires are critical for transferring power between the battery, inverter, motor, and charging system. Choosing the right type of HV cable not only affects vehicle performance, but also determines long-term safety, stability, and efficiency.

This guide explains everything you need to know—from material selection to wire size and insulation type—in plain language, whether you’re a technician, buyer, or product manager.

🚗 Why High Voltage Wires Matter in EVs

Unlike traditional vehicles that use low-voltage (12V or 24V) systems, electric vehicles use much higher voltages, typically up to 800V or even 1000V.

These high voltages enable:

Faster charging

More efficient power transmission

Smaller cable sizes for same performance

But with higher voltage comes more technical requirements and safety concerns, which is why proper wire selection is essential.

🧱 Key Characteristics of High Voltage Automotive Wires

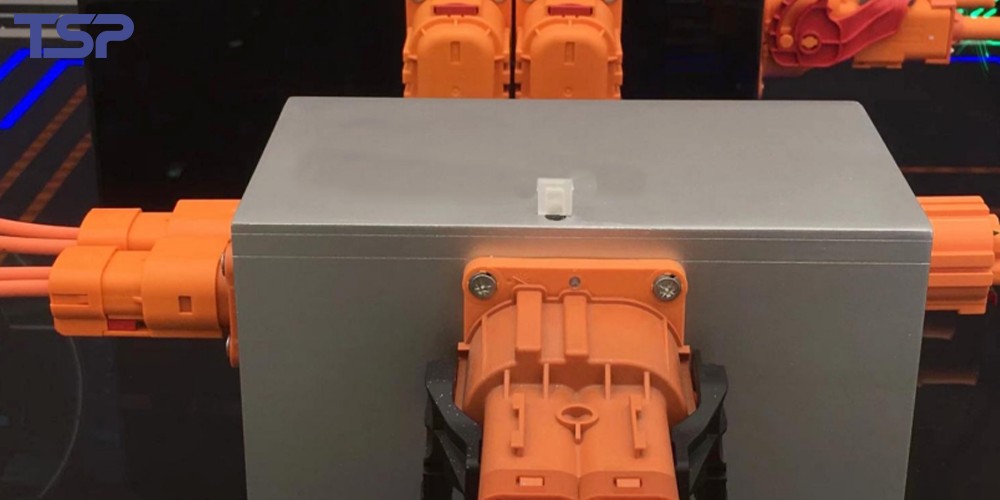

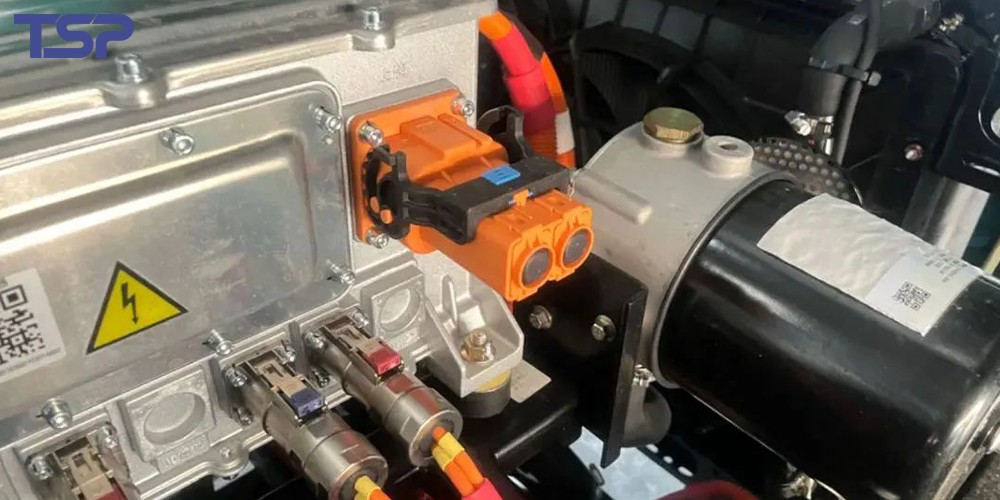

🟠 Color Identification

Orange is the standard color for high-voltage wires.

Often has a black or blue stripe to differentiate different signal or power lines.

Makes it easier to identify during installation or maintenance.

⚡ Voltage Rating

Most HV wires for EVs are rated for 600V–1000V DC.

Wires should pass high-voltage endurance tests like:

1000V for 30 minutes without breakdown

Instant surge test up to 5000V

🌡️ Temperature Resistance

Must withstand extreme temperature environments:

Continuous: -40°C to +150°C

Short bursts: up to 200°C

This protects the wire during fast charging, regenerative braking, or motor overheating.

🔰 Shielding (Electromagnetic Protection)

Motors, inverters, and battery systems generate EMI (electromagnetic interference).

Shielded HV cables protect other components (e.g., signal wires, ECUs) from interference.

Common shielding: tinned copper braid or aluminum foil, with high shielding effectiveness (≥85%).

🧪 Copper vs. Aluminum: Which Conductor to Use?

| Material | Best For | Advantages | Disadvantages |

|---|---|---|---|

| Copper | Most EV wiring | High conductivity, durable, easy to crimp/weld | Heavy, more expensive |

| Aluminum | Large cross-section cables (≥35mm²) | Lightweight, cost-saving | Lower strength, needs larger size |

🔍 Example:

To match the conductivity of 25mm² copper, you need around 42mm² aluminum.

👉 Aluminum cables are often used in battery-to-inverter connections or long-distance power delivery.

📏 How to Choose the Right Wire Size (Cross-Section)

Choosing the wrong wire size can result in:

Voltage drop (loss of power)

Overheating

Damage to insulation or connector

Worst case: fire or system failure

🔢 Key Considerations:

Operating Current

Match wire cross-section to your average load current

Use current–temperature derating curves provided by the cable manufacturer

Peak Load or Surge Current

During startup, acceleration, or fast charging, current can spike.

Wire must handle these brief surges without insulation damage

Ambient Temperature

Higher temperature = higher resistance

If routing through battery packs, engine rooms, or motor areas, choose a wire with extra heat tolerance

Fusing Coordination

Fuse rating should be lower than the point at which the wire emits smoke or burns

Always test wire + fuse combinations to ensure safe protection behavior

Connector Compatibility

Make sure the wire diameter fits into HV connector crimp barrels

Some systems use open-barrel or closed-barrel terminals

🧵 Types of High Voltage Wire Insulation Materials

| Type | Features | Use Cases | Pros | Cons |

|---|---|---|---|---|

| Silicone Rubber (SI) | Very soft, handles up to 180–200°C | Battery packs, internal wiring, BMS | Flexible, high temp | Tears easily, costly |

| Cross-linked Polyolefin (XLPO) | Tough and durable | Main power cables, underbody wiring | Good oil/abrasion resistance | Less flexible in cold |

| TPE/TPU | Thermoplastic, high strength | Robot arms, EV charging | Good balance of cost/flexibility | Lower temp than XLPO |

| Shielded Types | With copper braid or foil | Inverter, fast charger, motor wiring | Blocks EMI, stable signal | Higher cost, less flexible |

⚙️Common Applications for High Voltage Cables

| Application | Typical Cable Specs |

|---|---|

| Battery to Inverter | 50–70 mm², shielded XLPO, up to 1000V |

| Motor Drive Wiring | 25–50 mm², shielded, temp ≥150°C |

| On-Board Charger (OBC) | 10–16 mm², single or double shielding |

| High-Power Charging (Fast DC) | 70–95 mm², double shielded, highly heat-resistant |

| Battery Module Jumpers | 6–16 mm², flexible silicone wire, short length |

❓ Common Questions from Buyers

Q1: Can I use aluminum cables in place of copper?

✅ Yes, but the size must be increased, and terminals must support aluminum crimping.

Q2: What’s the most common size used?

🔌 Depends on the system, but 16 mm², 25 mm², and 35 mm² are popular for main power distribution.

Q3: Do I always need shielding?

💡 Not always. Shielding is needed near high-speed inverters, motors, and where EMI is a concern.

Q4: Can I use standard industrial cables for EVs?

⚠️ Not recommended. Automotive HV cables must meet standards like ISO 6722, LV 216, and ISO 19642.

🧠 Final Checklist Before You Choose:

✅ Confirm working voltage and peak current

✅ Select suitable conductor (copper or aluminum)

✅ Choose proper insulation type based on usage

✅ Ensure compatibility with connectors

✅ Verify standards compliance (ISO, LV, RoHS, etc.)

✅ Test with fuse + harness for real-world validation

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone