A Complete Guide for Manufacturers and Engineers

1. What Is Precision Injection Molding?

Precision injection molding is a manufacturing process used to make plastic parts that require tight dimensional tolerances, high repeatability, and consistent quality. This process ensures that every molded part comes out nearly identical—down to a fraction of a millimeter.

Compared to standard injection molding, precision molding uses more accurate machines, better molds, and tighter process controls. It is often used in industries like medical, electronics, aerospace, and automotive, where accuracy is critical.

2. What Makes It Different from Regular Molding?

The key difference lies in tolerance, repeatability, and part quality.

Precision molding can achieve tolerances of ±0.01 mm or even tighter. It also uses scientific molding techniques, which means each step—filling, packing, cooling, and ejection—is carefully controlled and measured.

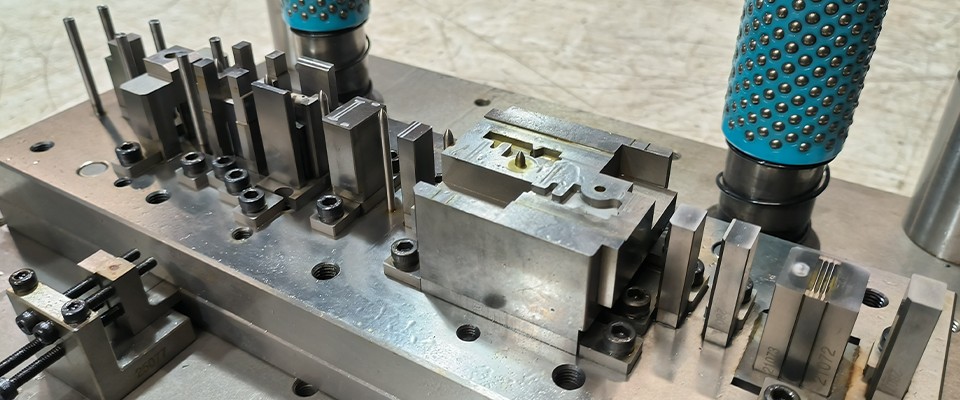

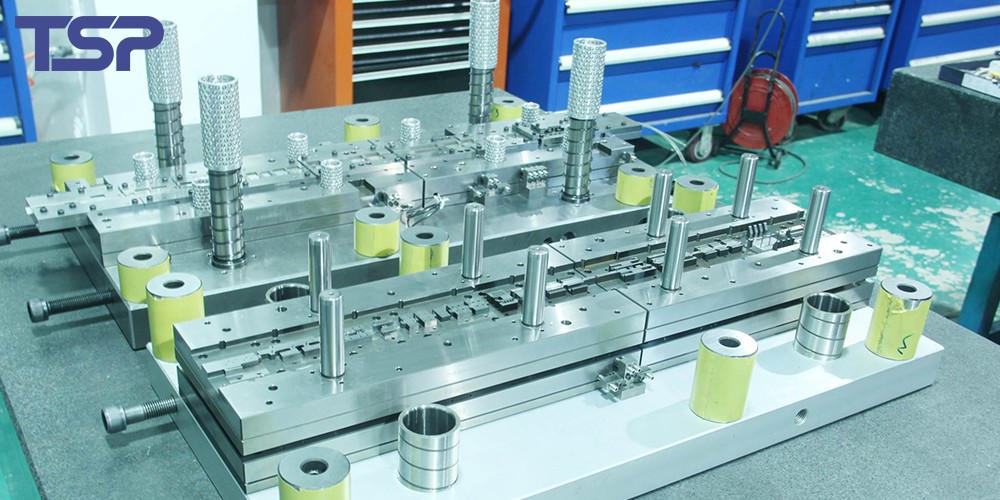

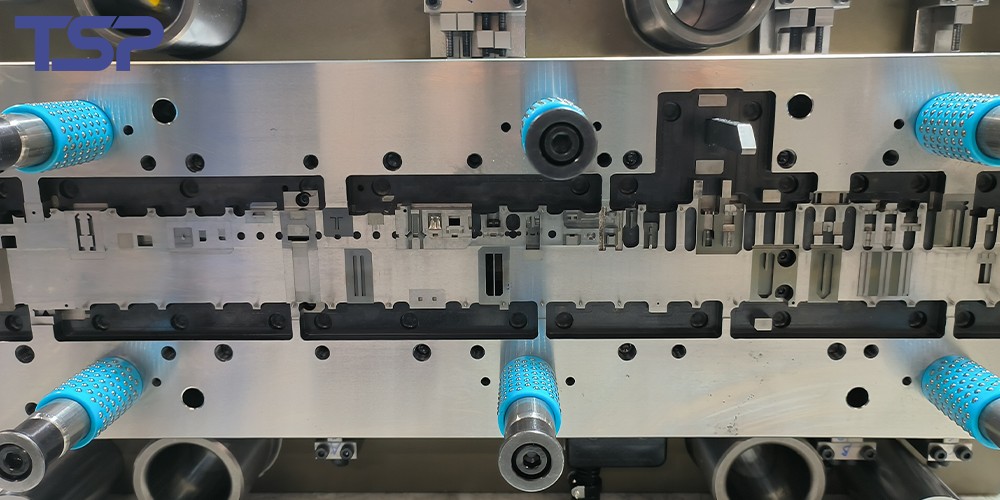

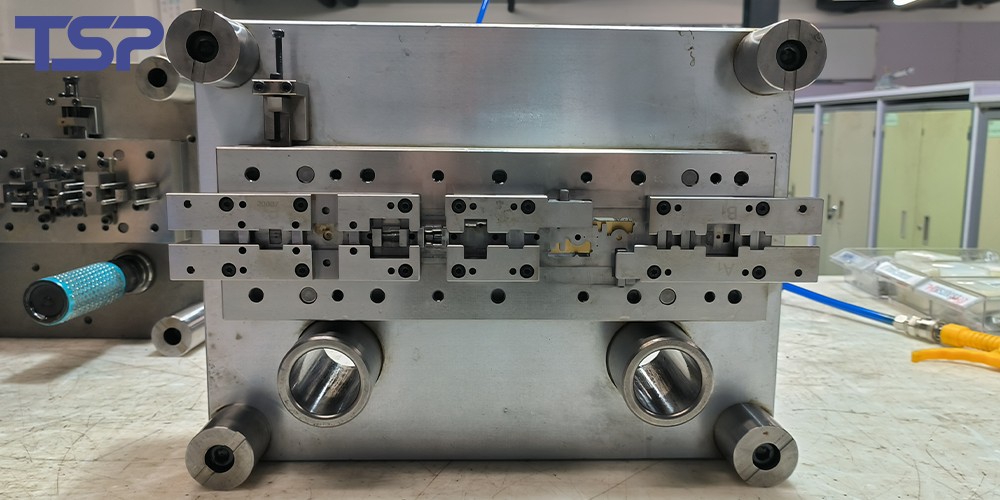

Another big factor is the mold itself. To get precise results, you need a high-quality mold that is built with accuracy and durability in mind. Poor molds can lead to part defects, inconsistent dimensions, and long-term costs.

3.Why the Mold Is So Important

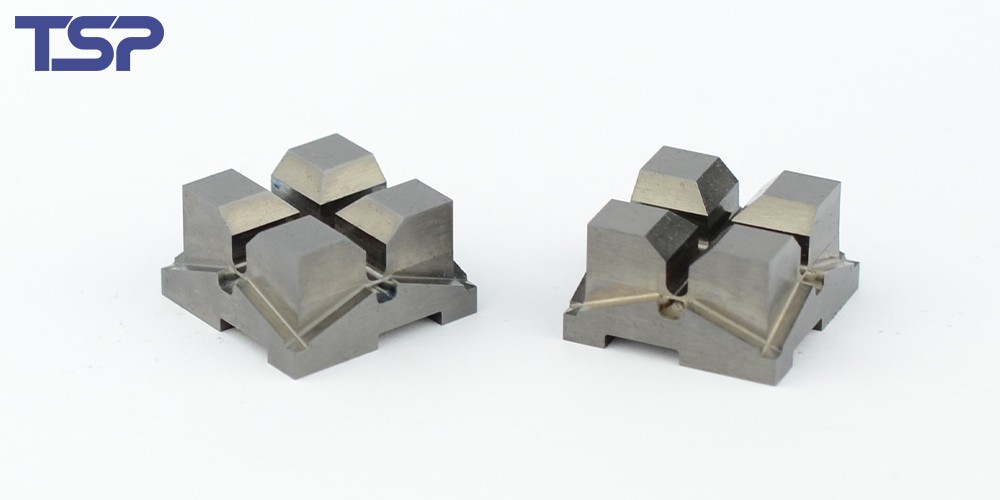

No matter how advanced the machine is, it cannot produce perfect parts without a well-designed mold. In precision molding, the mold must be:

- Built to very tight tolerances

- Made with high-hardness steel

- Designed for balanced flow and cooling

- Resistant to wear over millions of cycles

At TSP, we specialize in precision mold making. We focus on every detail to ensure your mold supports high-speed, high-accuracy production.

4. How Scientific Molding Supports Precision

Scientific molding is a method that uses data and sensors to control the molding process. Sensors placed inside the mold measure pressure, temperature, and material flow, so that the machine can adjust in real-time.

This improves part quality, reduces defects, and keeps each cycle consistent. Scientific molding is especially useful when working with complex or delicate parts where a small mistake could lead to failure.

5. Industries That Use Precision Injection Molding

Precision molding is used in industries where accuracy and performance are non-negotiable. Some key industries include:

- Medical devices – e.g., syringe components, inhalers, diagnostic tools

- Electronics – e.g., connectors, micro parts, sensor housings

- Automotive – e.g., interior clips, safety components

- Optics – e.g., lenses, camera casings

- Aerospace – e.g., lightweight structural elements

These applications often require parts that are tiny, complex, and must function perfectly over time.

6. What Tolerances Can You Expect?

| Feature | Standard Molding | Precision Molding |

|---|---|---|

| Tolerance | ±0.05–0.1 mm | ±0.005–0.01 mm |

| Part Consistency | Moderate | High (6σ or better) |

| Mold Lifespan (steel mold) | 100,000–500,000 shots | 1,000,000+ shots |

| Surface Finish | Basic | Glossy or optical |

7. Advantages of Precision Molding

Here are some key benefits of using precision injection molding:

- ✅ Better part consistency – Every part meets the design spec

- ✅ Fewer defects – Less rework and waste

- ✅ Faster cycles – Especially when paired with good cooling design

- ✅ Automation ready – Works well in robotic assembly lines

- ✅ Supports micro parts – Ideal for small, high-precision parts

8. Why Precision Starts with the Mold

If you want precise parts, you need a precise mold. It’s the most important part of the whole process. A poor-quality mold causes warping, flashing, short shots, and delays.

At TSP, we help manufacturers build better products by supplying custom precision molds that match the tightest tolerances and the toughest production demands.

Additional Insight 1: Materials Matter

Choosing the right plastic material is just as important as the mold. Precision molding often uses materials like PPS, PEEK, PC, and LCP that have low shrinkage and stable flow.

We can help you match your design needs with the right material to reduce warpage and improve dimensional control.

Additional Insight 2: Maintenance Equals Performance

Even the best mold needs proper care. Regular maintenance and polishing keep surfaces clean and the mold cavity within tolerance. Our molds are built for long tool life and come with documentation and support to make maintenance easier.

Additional Insight 3: Cost vs. Value

Precision molding may cost more upfront—but the long-term savings in part quality, lower scrap rates, and shorter cycle times can easily pay off. When you choose a high-end mold, you’re investing in stable production and higher profits.

Additional Insight 4: Partnering with a Mold Expert

Many molding defects come from mold design problems. That’s why it’s smart to work with an experienced mold maker who understands your product and production needs.

We don’t just make molds—we help you optimize your entire molding process.

9. Ready to Start Your Precision Molding Project?

If you’re building high-performance parts that need to meet tight tolerances, we can help. Contact our team today to learn how our custom precision molds can bring your project to life.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone