In today’s car industry, cars are quickly becoming smart and connected. The wiring harness is important, even if it goes unnoticed. This small part powers your headlights, connects your infotainment system, and coordinates your engine sensors. It makes sure everything works smoothly behind the scenes.

But what exactly is a wiring harness in a car, and why is it so essential in today’s vehicles?

This article gives a clear overview of automotive wiring harnesses. It combines technical details with real-world uses. This is good for engineers and buyers. Also, it is helpful for anyone who wants to learn about high-performance wire harness solutions.

What Is a Wiring Harness in a Car?

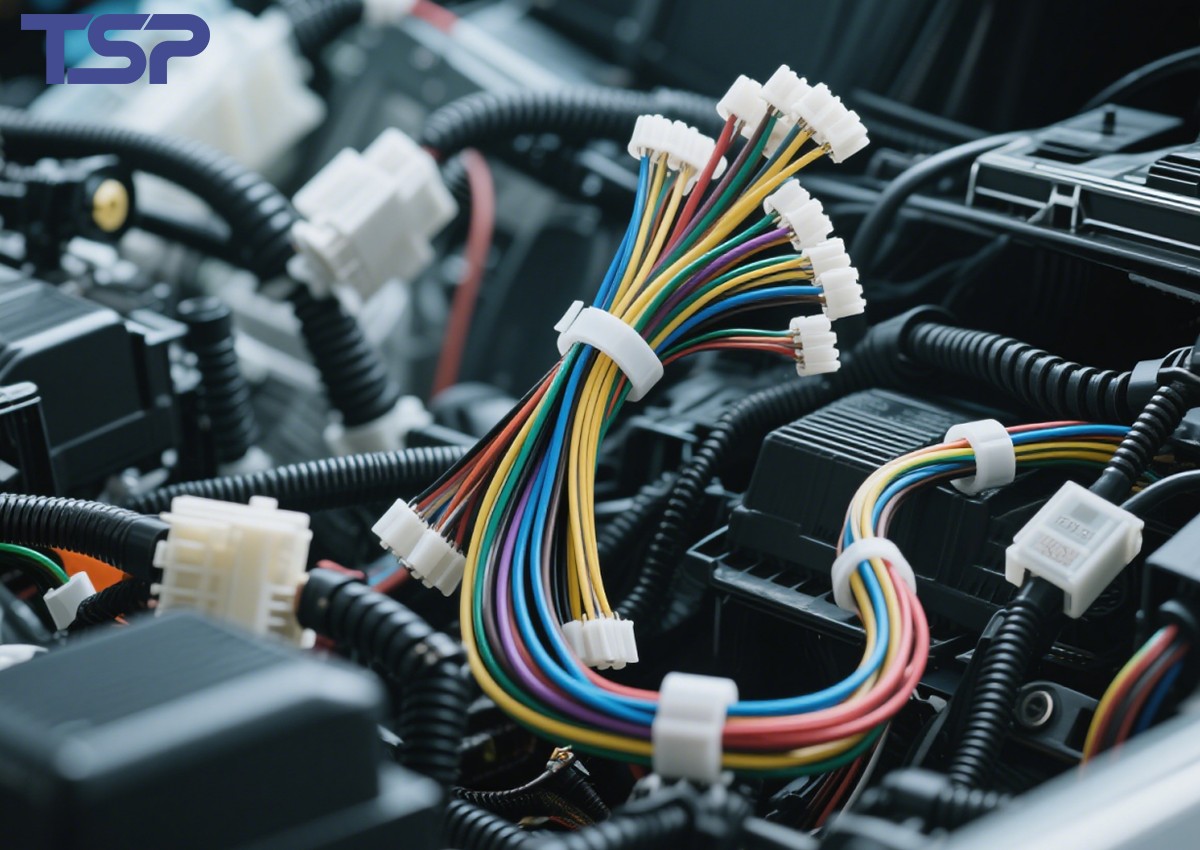

A wiring harness, also called a cable harness or wire loom, is a set of electrical wires. It includes terminals, connectors, and protective sheaths. Engineers bundle these components together to efficiently transmit electrical power and signals to different parts of the car.

Think of the wiring harness as the central nervous system of your vehicle. Just like your body uses nerves to send signals from your brain to your limbs, a car uses wiring harnesses. These harnesses send signals from control modules to actuators, lights, sensors, and more.

Without a wiring harness, each car part would need its own wire. This would create a messy and confusing situation. It would also increase weight, cost, and the chance of errors.

What Does a Wiring Harness Do?

The core functions of a car wiring harness include:

- Power Distribution: Supplying electricity from the battery or alternator to various systems (engine control, lighting, infotainment, etc.)

- Signal Transmission: Sending data and commands between control units and devices (e.g., from sensors to the ECU)

- Protection & Organization: Preventing shorts, abrasion, moisture ingress, and electromagnetic interference (EMI)

- Ease of Assembly: Enabling modular assembly on car production lines, reducing labor time and error rates

Real-World Example:

When you turn on your car’s ignition:

- The engine control harness delivers power to the starter motor

- The dashboard harness activates indicators and warning lights

- The body harness unlocks doors and turns on courtesy lights

All this happens within milliseconds, thanks to the coordinated wiring infrastructure.

Components of a Car Wiring Harness (with More Depth)

| Component | Description |

|---|---|

| Wires | Typically copper or aluminum; carry current and signals across systems |

| Terminals | Connect wire ends to plugs or metal contact points for circuits |

| Connectors | Plastic housings holding multiple terminals; enable plug-and-play systems |

| Insulation | Protects wires from heat, oil, water, vibration (often PVC, XLPE, or Teflon) |

| Fuse Holders | Protect circuits from overcurrent |

| Shielding Foils | Block EMI for critical signal cables like CAN bus or audio wires |

| Grommets/Seals | Prevent water or dust from entering junction points |

| Tapes & Sleeves | Bundle wires together and reduce friction during vibration |

You must carefully choose each of these parts. This choice depends on a few factors.

It depends on the vehicle’s voltage. It also depends on the temperature areas. Lastly, the location where someone uses the vehicle, such as the engine bay or passenger cabin, determines the outcome.

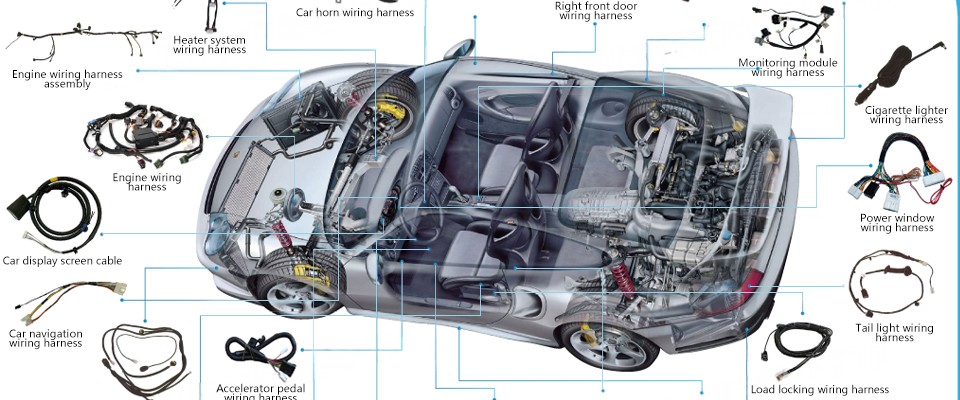

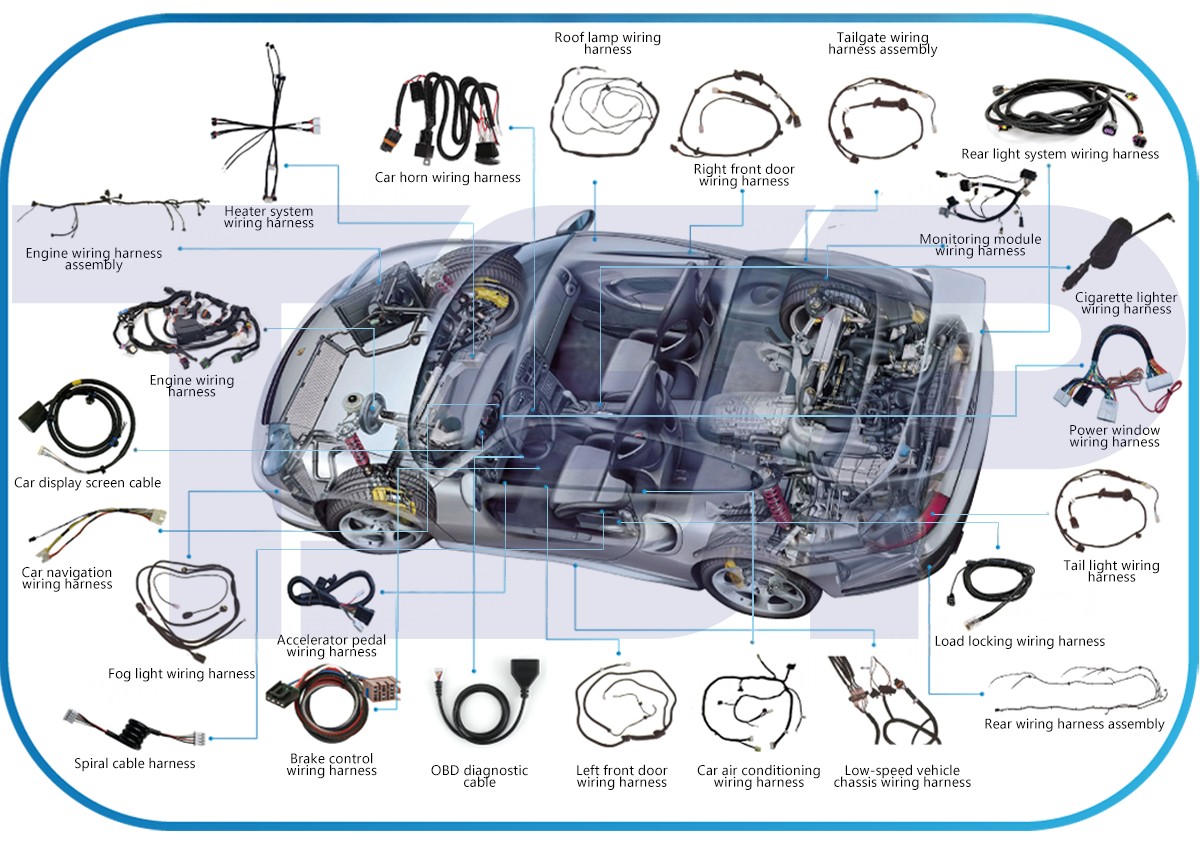

Where Are Wiring Harnesses Found in a Car?

The vehicle spreads out the wiring harnesses. Manufacturers usually design each harness for a specific purpose or area. Common types include:

1. Engine Wiring Harness

- Connects ECU with ignition system, injectors, crankshaft sensors, oxygen sensors

- Must endure extreme heat and vibration

2. Chassis Harness

- Controls brake lights, fuel pump, ABS, and rear components

3. Dashboard Harness

- Links the instrument cluster, infotainment, climate control, warning lights

4. Body Harness

- Powers locks, windows, mirrors, wipers, seat heaters

5. Lighting Harness

- Runs from fuse box to headlights, taillights, fog lights, indicators

6. Battery & High-Voltage Harness (in EVs)

- Used to transfer power in hybrid/electric vehicles

- Requires robust insulation and shielding

Why Is the Wiring Harness So Important?

The wiring harness is usually the second most expensive part of making a car, right after the engine. That’s because it:

- Reduces manufacturing errors

- Improves safety by preventing short circuits

- Reduces weight vs individual wire runs

- Enhances modularity and diagnostic access

- Simplifies repair and maintenance (via OBD, module systems)

🚗 A luxury car may contain over 70 individual harnesses and more than 5 kilometers of wiring!

What Happens If a Wiring Harness Fails?

When someone damages a wiring harness or it stops working, it can cause serious electrical problems. These issues can range from small glitches to total system shutdowns. A broken wire in the engine harness can cause misfires, starting issues, or turn on the check engine light. A corroded connector in the lighting harness could result in headlight failure, posing safety risks on the road.

In many cases, identifying wiring harness faults requires specialized diagnostic tools and visual inspection for worn-out insulation, melted sheathing, or damaged terminals. Choosing a high-quality, well-made harness lowers the chances of downtime, warranty claims, and repair costs. At our factory, every harness undergoes 100% electrical testing to guarantee long-term performance in real-world conditions.

Customization for Diverse Vehicle Applications

Different types of vehicles demand different wire harness designs. For instance:

- Electric vehicles (EVs) require harnesses with strong insulation for high voltage. They also need lightweight aluminum wires and smart routing to handle battery packs and inverters.

- Heavy-duty trucks and agricultural vehicles require rugged, waterproof harnesses that can withstand mud, vibration, and extreme temperatures.

- Luxury cars and smart vehicles need CAN-bus and Ethernet-capable harnesses to support advanced infotainment and ADAS systems.

This is where custom wire harness manufacturing becomes essential. We provide full customization services. This includes layout planning, connector selection, EMI shielding, and environmental protection. We aim to meet the specific needs of your industry or application.

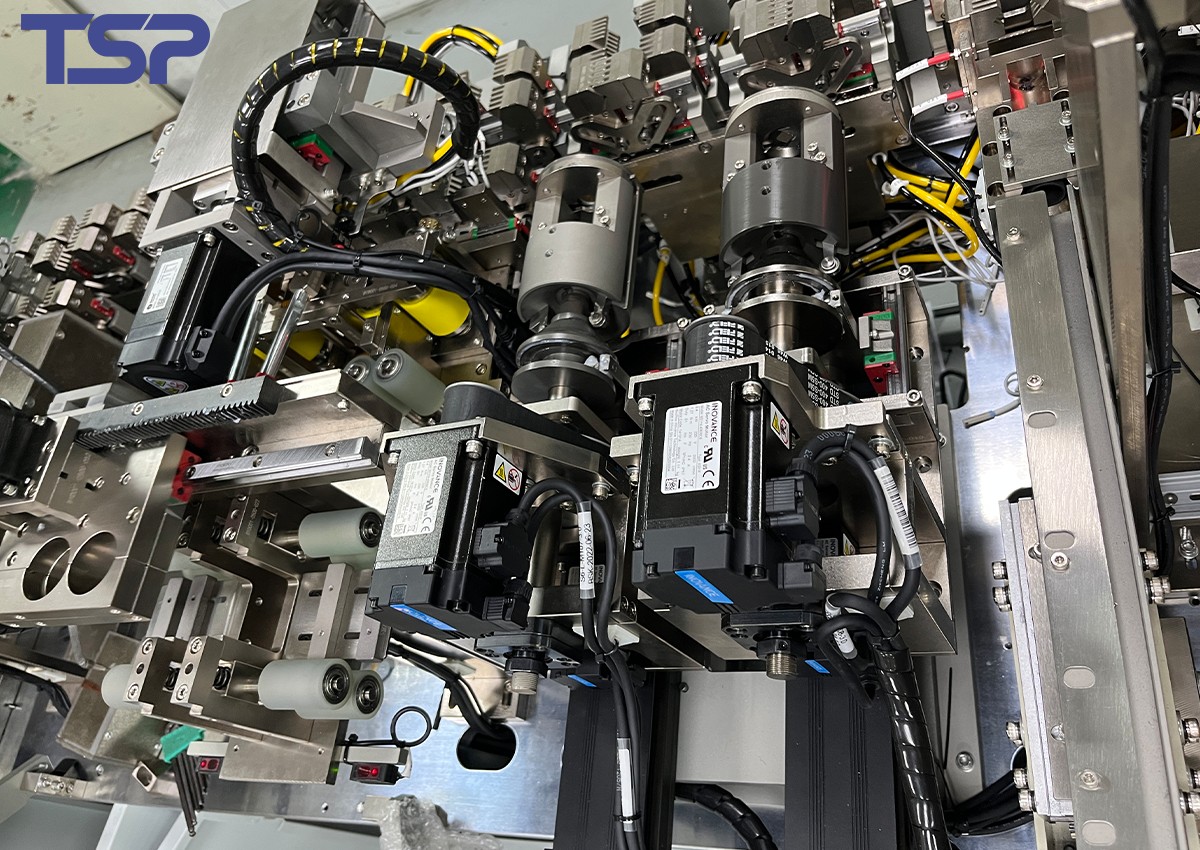

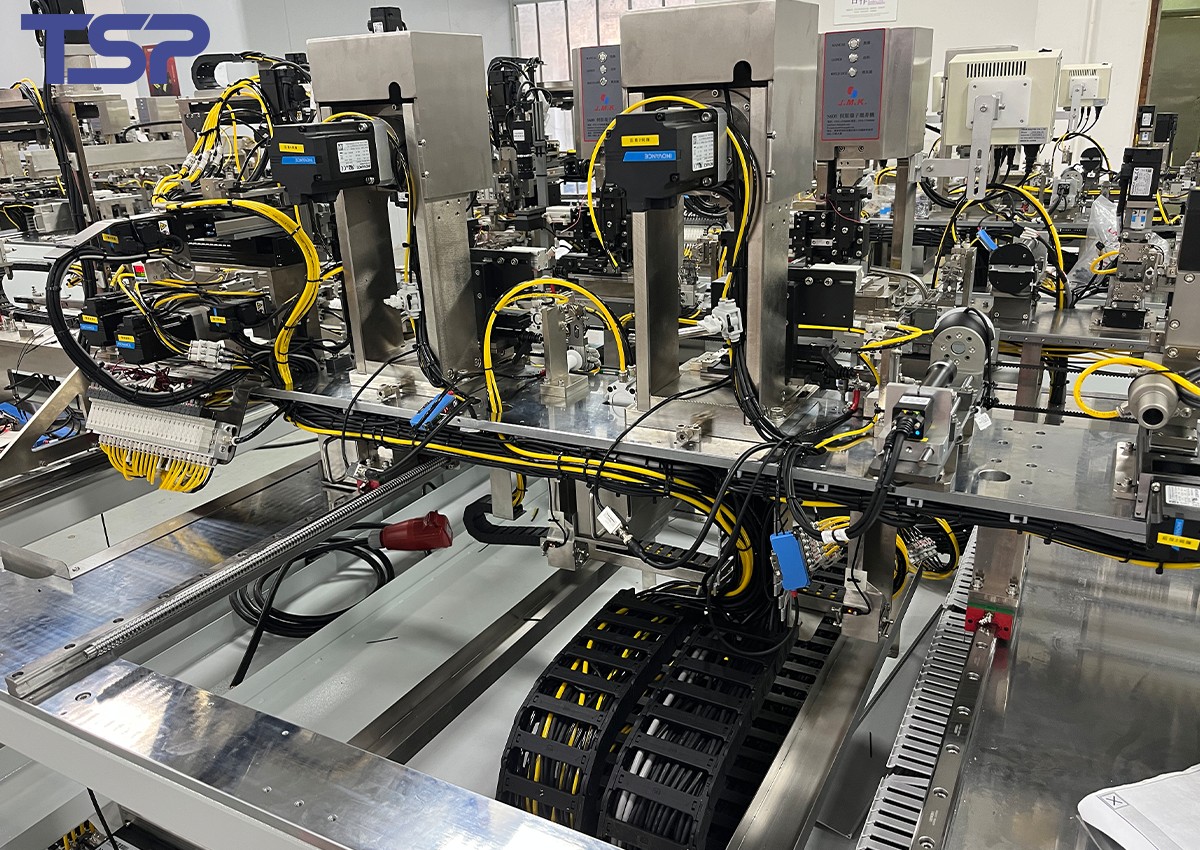

How Is a Wiring Harness Manufactured?

Producing a wire harness is labor-intensive and highly customized, often following these stages:

- Design & Routing Plan (using CAD)

- Wire Cutting & Stripping

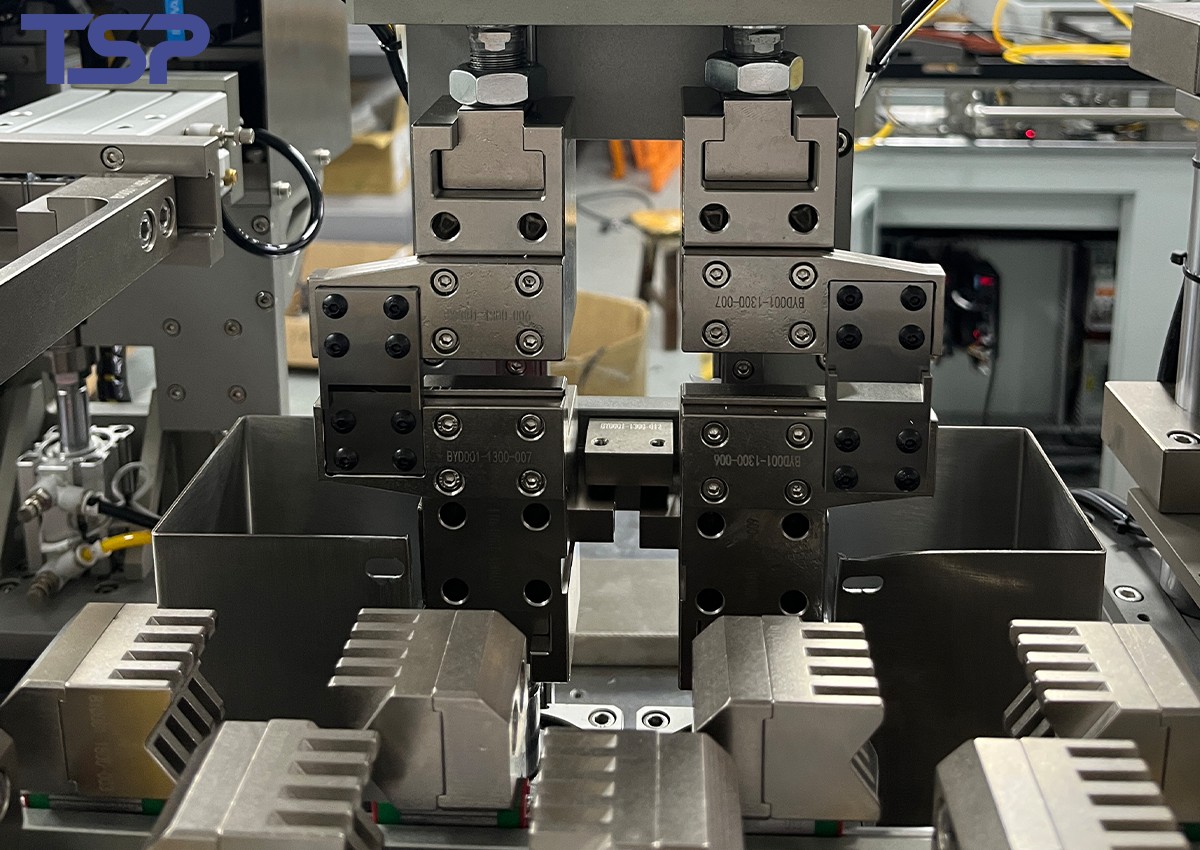

- Crimping Terminals and Pins

- Insertion into Connectors

- Bundling with Sleeves or Tapes

- Electrical Testing (continuity, resistance, insulation breakdown)

- Labeling, Packing, and Quality Control

Precision matters: even a single loose crimp can cause system failure.

What Makes a High-Quality Wiring Harness?

A premium wire harness is defined by:

- Precise assembly tolerance (especially for sensor/signal wires)

- Automated crimping & testing

- Environmental sealing (IP67 or higher)

- Material compliance (UL, RoHS, CE)

- Smart routing design (low EMI, thermal balancing)

As a precision harness manufacturer, we use advanced technology and strict testing methods. This ensures long-lasting performance for both high-speed EVs and tough off-road trucks.

Trends Driving the Future of Automotive Wiring

- Electric Vehicles (EVs): Require lightweight aluminum harnesses, better heat management, high-voltage routing

- Autonomous Systems: Need more sensors and data transfer cables (Ethernet, CAN, LIN)

- Smart Connectivity: Integration with smartphones, apps, cloud diagnostics

- Flexible Printed Circuits (FPC): Replacing bulky bundles in dashboards

- Weight Reduction: OEMs pushing to cut 1–2kg per vehicle via harness redesign

Why Partner with Us for Precision Automotive Harnesses?

We are not just wire assemblers—we are engineers, problem-solvers, and innovators. Here’s what sets our wire harnesses apart:

| Feature | Your Benefit |

|---|---|

| ISO/TS-certified factory | Guaranteed quality and compliance |

| Custom harness engineering | Tailored to your specs, applications, and environments |

| Full-service OEM/ODM | Design → Prototyping → Production |

| Specialized in tight tolerance | Ideal for EVs, sensors, and medical harnesses |

| Global supply capabilities | On-time delivery, logistics coordination |

Whether you’re building electric vehicles, agricultural equipment, robotics, or medical devices, we help you stay ahead of the curve.

Get in Touch

Need a customized automotive wiring harness that balances cost, weight, durability, and precision?

📩 Contact us today to request a sample, discuss your technical specs, or get a quote. Let us bring 20+ years of expertise into your product’s wiring backbone.

Conclusion

A car’s wiring harness is its lifeline—silently connecting every electronic system and enabling the modern driving experience. With vehicles getting smarter and more electrified, the demand for high-performance, custom wire harnesses is greater than ever.

As a precision harness manufacturer, we are here to help you meet your needs. We offer tailored solutions, high quality, and great reliability.

To read more: TSP Shanghai Achieves 1000KW Solar Power Milestone