Our vision is to be your trusted partner in creating life-saving medical devices. With a focus on reliability and durability, we are dedicated to delivering exceptional value by upholding the standards that matter most to you. Through continuous innovation and a comprehensive product range, we help medical device OEMs—both large and small—turn ideas into impactful solutions.

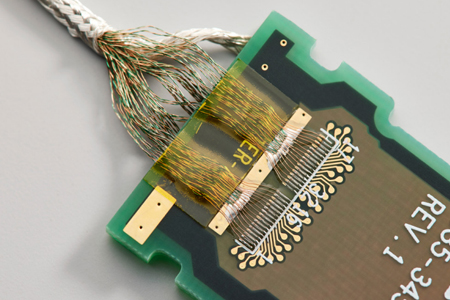

TSP provides a convenient one-stop solution for custom connectors, cables, and cable assemblies designed for visualization systems in catheters and various imaging systems. Our connectors, cables, and assemblies are engineered to work seamlessly together, accommodating a range of complexities to enhance overall performance. We offer solutions with high pin counts (up to 612 pins), zero insertion force, compact sizes, fine pitch, high durability cycle life, and shielded connectors, enabling efficient transmission of power, data, and signals.

We’re more than just a components supplier. With TSP, you gain an integrated solutions partner capable of developing your idea from prototyping through to volume manufacturing. This connected value offers you a competitive edge in today’s fast-paced marketplace.

We are a vital partner in transforming your ideas into reality with speed and precision. This is where the commitment to lasting connections becomes tangible – collaborating with customers to drive innovation in key medical specialties.

Supplying leading medical device companies with essential components and sub-assemblies to create interventional devices for diagnosing and treating cardiovascular conditions.

A comprehensive range of technologies, capabilities, and services to support the development of components for robotic surgery, laparoscopy, and electrosurgical systems.

A wide selection of miniaturized components and sub-assemblies designed to enhance ergonomics and data acquisition, driving the development of advanced high-density imaging devices.

Assisting IVD manufacturers in the design, development, testing, and production of innovative point-of-care IVD technologies utilizing microfluidic platforms.

From standard and custom metal shafts and hypotubes to specialized high-density cable assemblies and medical-grade polymers, TE offers the scale, global reach, and expertise across a variety of manufacturing processes. This unique blend enables us to transform your concepts into reality—whether your project requires a trusted partner in metals, polymer extrusions, laser processing, connectors, cables, or other specialized capabilities.

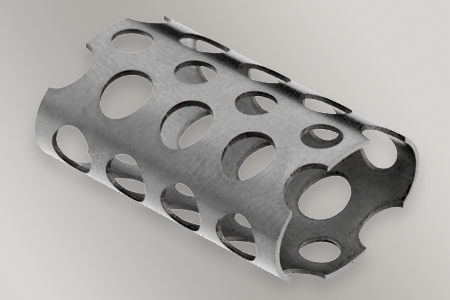

Our advanced laser welding and cutting capabilities enhance the manufacturing of catheters and guidewires, offering greater flexibility in materials and design options.

With expertise in fine wire termination as small as 0.004 inches in pitch, we enable the packaging of a high volume of signal or energy-delivery channels within a compact form factor.

Our production process flow outlines each step in the manufacturing journey, from initial design and material selection to final assembly and quality testing. By integrating advanced technologies and streamlined procedures, we ensure precision, efficiency, and consistent quality at every stage, delivering reliable and innovative products to meet our customers’ needs.

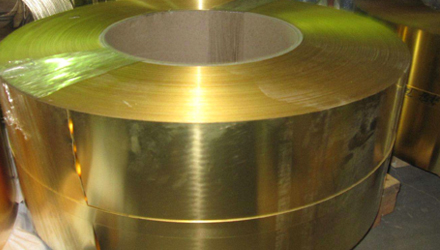

Material Selection – Use of Imported High-Quality Raw Materials

TSP selects premium international-grade 59-1 (Special Grade A) brass, also known as instrument-grade brass. It has a high copper content, superior hardness, minimal impurities, and is resistant to deformation. This results in smoother current signal transmission and a lower signal loss rate.

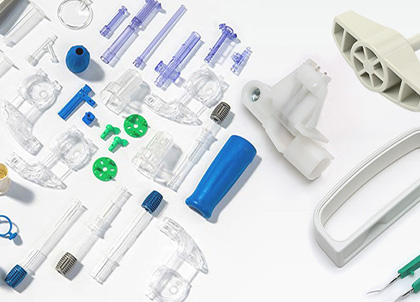

Material Selection – High-Quality Plastic Granules

We use premium-grade plastic granules with properties specifically suited for medical products, ensuring the production of new, high-performance materials for optimal functionality and safety.

Stamping – High-Speed Integrated Stamping

TSP uses 21 large-scale high-speed stamping machines imported from abroad to stamp the pins into a single integrated form, ensuring product quality and filtering out products with twists, cracks, or deformation.

Plating – 5-Layer Plating Process

On a fully automated 65-meter circular plating line, the products undergo a five-layer plating process, ensuring they can withstand temperatures of 260/280°C.

Rigorous Testing – Passed 24-hour salt spray test.

Injection Molding – Precision Molding Process

With 35 injection molding machines imported from abroad, TSP uses high-performance PET plastic materials to ensure reliable performance even under long-term high-temperature conditions. The excellent electrical insulation and export-standard injection molding process guarantee the product’s longevity.

Assembly – Fully Automated Assembly Process

Various components are assembled through fully automated systems, ensuring quality and the removal of defective products. The meticulous control over surface appearance reflects strict technical standards and demonstrates TSP’s commitment to delivering exceptional quality.

Testing – Rigorous Quality Control to International Standards

With stringent testing procedures, each product is individually inspected by quality control personnel. The products undergo salt spray testing and 280°C high-temperature testing to ensure no defects are overlooked.

Get the latest on industry solutions:

With the rapid growth of the medical injection molding industry, manufacturers are facing an increasing number of challenges. From meeting

Medical injection molding products play a critical role in ensuring patient safety and effective medical treatment. However, product quality doesn’t

In the rapidly evolving world of medical technology, connectors play a critical role in ensuring the proper functioning and safety

We’re here to help you find the right connector and sensor solutions for your mobility needs. Reach out to us for more information or to discuss your project